Same, I was used to sharpening tools and knives.Yes indeed. I didn't. And I was applying most of that excessive pressure to the spine, where it did very little except wear out the razor prematurely.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dilemma

- Thread starter kayvee

- Start date

Slash McCoy

I freehand dog rockets

Not using 9µ film? Why not? If you are wearing out the 3µ trying to remove the bevel set scratches, and failing, and you are getting 9µ film included in your film kit, USE it. From 9 to 3 is a pretty manageable jump. I do it routinely.

- Thread starter

- #23

- Thread starter

- #24

You should lap it. It probably isn't very flat (mine wasn't) and it tends to get a little glassy between uses, for me. No need to soak, it doesn't take on a lot of water. Just keep the surface wet when you're using it.BTW, I received my Naniwa Fuji 8K today and it is super smooth to touch. Does this even need to be lapped before first use? Does it need to be soaked?

Slash McCoy

I freehand dog rockets

You tell us. You are running quickly through your 3µ. I get at least a dozen razors from a piece of film.I use my Shapton Pro 1500 to set bevel and I hope am setting the edge properly. Is the 9um still necessary afterwards?

If you KNOW that your plate is very flat, then try this. Right off the 1500, hit the bevel with your sharpie. Set up your 9µ film and give it a couple of laps, no more, and examine your bevel. If your shapton was doing its job, you should see that you have extremely good contact all along the bevel all the way out to the edge, and BTW, no sparklies with the edge turned straight up at your eye and tipped forward and back. That will tell you a bit more on whether or not you need it.

Are you honing in hand, or on the bench?

- Thread starter

- #27

I ran through an entire sheet honing one razor. Some of it was me learning. Some of it was not realizing my razor had a warp and that I had to have a different movement on the hone. Some of it was learning that movement and ripping the edges of the film in the process. Long story short, the last strip of film looks like this now.I get at least a dozen razors from a piece of film

Great suggestion, I'll try this out and report.If you KNOW that your plate is very flat, then try this. Right off the 1500, hit the bevel with your sharpie. Set up your 9µ film and give it a couple of laps, no more, and examine your bevel. If your shapton was doing its job, you should see that you have extremely good contact all along the bevel all the way out to the edge, and BTW, no sparklies with the edge turned straight up at your eye and tipped forward and back. That will tell you a bit more on whether or not you need it.

Are you honing in hand, or on the bench?

I found that I couldn't do both the movement I needed to execute and the appropriate pressure with one hand and the hone in the other. So I honed on the bench.

My journey is documented in this thread as well. Observing the edge under a scope - https://www.badgerandblade.com/forum/threads/observing-the-edge-under-a-scope.640325/

Slash McCoy

I freehand dog rockets

pretty much any stone should get lapped when you receive it. If it is already flat then it only takes a half dozen laps to prove it, so not much stone wasted. And then you KNOW it is flat, no question about it, if you use a valid method.BTW, I received my Naniwa Fuji 8K today and it is super smooth to touch. Does this even need to be lapped before first use? Does it need to be soaked?

Slash McCoy

I freehand dog rockets

There's your problem, or at least a part of it. When you hone in an unsupported hand, it gives. It yields. It rolls as needed. It aligns itself and it is easy to regulate pressure. Many beginners will furiously and desperately try to control the razor with two hands, and you need to accept the fact that even a milling machine is not capable of the sort of accuracy you are striving for as you attempt to be a machine instead of an organic carbon based unit. Hone in hand. Let it happen. It takes longer to learn to bench hone properly than to hone in hand. An expert will get the same results either way. A beginner should hone in hand.I ran through an entire sheet honing one razor. Some of it was me learning. Some of it was not realizing my razor had a warp and that I had to have a different movement on the hone. Some of it was learning that movement and ripping the edges of the film in the process. Long story short, the last strip of film looks like this now.

View attachment 1674645

Great suggestion, I'll try this out and report.

I found that I couldn't do both the movement I needed to execute and the appropriate pressure with one hand and the hone in the other. So I honed on the bench.

My journey is documented in this thread as well. Observing the edge under a scope - https://www.badgerandblade.com/forum/threads/observing-the-edge-under-a-scope.640325/

Also, keep the shoulder off the honing media whether you use film or stone.

That is a good stone. Maybe you can manage a jump from 1500 to 8k if you use it with diamond plate slurry, followed by enough water only laps to finish. It is a quick forgiving stone.BTW, I received my Naniwa Fuji 8K today and it is super smooth to touch. Does this even need to be lapped before first use? Does it need to be soaked?

Otherwise, the Hayabusa 4k slots perfectly between the Shapton 1.5 and the Fuji and it is not terribly expensive. I've never tried going straight to the 8k...not something that particularly interests me, but it may work.That is a good stone. Maybe you can manage a jump from 1500 to 8k if you use it with diamond plate slurry, followed by enough water only laps to finish. It is a quick forgiving stone.

rbscebu

Girls call me Makaluod

From the look of your 3μm film, you are allowing the stabiliser and possibly the shoulder of your SR to ride up onto the honing surface. You need to pay more attention to prevent this.I ran through an entire sheet honing one razor. Some of it was me learning. Some of it was not realizing my razor had a warp and that I had to have a different movement on the hone. Some of it was learning that movement and ripping the edges of the film in the process. Long story short, the last strip of film looks like this now.

View attachment 1674645

Great suggestion, I'll try this out and report.

I found that I couldn't do both the movement I needed to execute and the appropriate pressure with one hand and the hone in the other. So I honed on the bench.

My journey is documented in this thread as well. Observing the edge under a scope - https://www.badgerandblade.com/forum/threads/observing-the-edge-under-a-scope.640325/

Please hone with your lapping film substrate held in your unsupported non-dominant hand. @Slash McCoy is totally correct in this. It is only after you are getting consistently great results from in-hand honing that you should consider honing on-bench.

It may feel awkward initially to hone in-hand but many things in SR shaving feel that way at first. Again like SR shaving, it won't be long before in-hand honing starts to feel quite natural.

Being able to hone knives in hand with pocket stones was really the only skill from knife sharpening that translated into razor honing, and I'm greatful for it. When I started honing razors I had some problems because I was honing on the bench, but once I got my first old washita and started doing razors in hand it got much much easier. I can hone a razor pretty quickly if the bevel is set.There's your problem, or at least a part of it. When you hone in an unsupported hand, it gives. It yields. It rolls as needed. It aligns itself and it is easy to regulate pressure. Many beginners will furiously and desperately try to control the razor with two hands, and you need to accept the fact that even a milling machine is not capable of the sort of accuracy you are striving for as you attempt to be a machine instead of an organic carbon based unit. Hone in hand. Let it happen. It takes longer to learn to bench hone properly than to hone in hand. An expert will get the same results either way. A beginner should hone in hand.

Also, keep the shoulder off the honing media whether you use film or stone.

In the beginning, removing as many variables as possible is always best. If the razor is warped, get a razor that isn't. If your not sure your stones are flat, lap them.

Be actively involved in the process, watch the undercut, listen to the sound, feel the razor on the stone. Take notes.

There are many threads here about bevel setting, read them, be 100% sure you have a good bevel before moving on. I think the two hardest things for beginners are a good bevel set and using too much pressure.

Be actively involved in the process, watch the undercut, listen to the sound, feel the razor on the stone. Take notes.

There are many threads here about bevel setting, read them, be 100% sure you have a good bevel before moving on. I think the two hardest things for beginners are a good bevel set and using too much pressure.

It will absorb a little water slowly for about 5 minutes. You can either continue to spray it or soak it for 5 minutes. Once saturated the water will pool on top without soaking in.BTW, I received my Naniwa Fuji 8K today and it is super smooth to touch. Does this even need to be lapped before first use? Does it need to be soaked?

It will go out of flat between uses, almost like the surface grows in places, so it must be flattened before each use. This is more pronounced early on when the stone is new.

It is an outstanding stone both for razors and knives. Interestingly fast for its grit level. Hard but just soft enough to make it easy to flatten and clean.

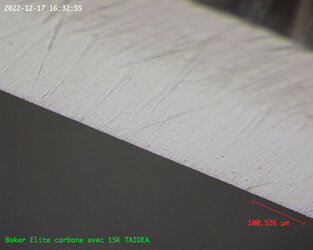

Is that an empirical statement? I do agree we should advice newcomers to buy hones that are approved and time tested by experienced honers, however, defining something as being "garbage" without personal experience should IMO be discouraged. In this case, Taidea is a professional company that is very serious about these new type of hones. When these first came out, they had some problems caused by temperature and humdity during the hardening process, what made them "sweat" and lose tiny pieces. When I contacted Taidea about it, they assured me these problems are solved now and they offered me a complete new set without charges. I will soon be testing them and will report afterwards. The reason I did not give up on them is because the edge off the 15K (0.62µ!) feels exceptionally sharp and smooth, even natural. If the new set does not show the problems I had with the earlier ones, I'll be happy to endorse them!The working assumption should be that the stones you are considering are garbage. You would be much better off getting one or two more good stones for the same amount of money you are considering spending on garbage.

I think that might even be better, or at least as good as the shapton 16k in terms of the final finish.Je confirme les très bons résultats de la pierre de verre Taidea 15KView attachment 1681183

Fair enough. I had cranked up the intensity in my words because the persuasion situation seemed to call for it. I was unaware that the serious problems had been claimed to be fixed.Is that an empirical statement? I do agree we should advice newcomers to buy hones that are approved and time tested by experienced honers, however, defining something as being "garbage" without personal experience should IMO be discouraged. In this case, Taidea is a professional company that is very serious about these new type of hones. When these first came out, they had some problems caused by temperature and humdity during the hardening process, what made them "sweat" and lose tiny pieces. When I contacted Taidea about it, they assured me these problems are solved now and they offered me a complete new set without charges. I will soon be testing them and will report afterwards. The reason I did not give up on them is because the edge off the 15K (0.62µ!) feels exceptionally sharp and smooth, even natural. If the new set does not show the problems I had with the earlier ones, I'll be happy to endorse them!

I did qualify it with "working assumption," which pretty clearly took it out of the realm of empirical statements, or at least that's what I intended. I suppose if I were writing it now, I'd say something like "as a new honer, you should think of these stones as a high-risk situation, unless there are very clear reports of good honing experiences on the exact stones you are considering, from people who have honed a lot of razors"

It's not about the looks but about how it shaves but to me, that is where it stands out. It is plenty sharp, super smooth ,skin friendly and has the most "natural" feeling I have ever come across with any synthetic hone. However, there were problems with some badges of these stones in the past. According to Taidea these problems are solved now and I will be testing a new set soon and will report.I think that might even be better, or at least as good as the shapton 16k in terms of the final finish.