The following instructions will enable you to measure the blade gap of most typical safety razors to an accuracy of +/- .001 inch.

The following instructions are revised from the earlier post

and I hope easier to follow ...

=================

IDEA !!!

=================

If we could find a few razor owners who would calculate blade gap measurements to replicate/verify each other's results we can easily create a comprehensive table of relative blade gap measurements.

Background:

Here's the trick ...

Imagine I have a photograph showing myself standing by a tree.

My image, in the picture, measures only 1 inch (head to foot).

The tree, in the picture, is 2 inches from it's highest branch to the ground.

But ...

I know my "actual" height is 6 feet.

Since the tree, in the picture, is 2 inches = 2x taller than me, in the picture,

the tree must be 2x6 feet in reality or 12 feet tall.

Now imagine that I have a photograph of the head of a razor - straght on looking "into the gap between the blade edge and the safety bar.

If I zoom in (or magnify it) by some factor I could increase the head's length on the screen to say 50 inches.

My image is now much too big to be contained entirely on the screen but if I scroll to the part of the image where the gap appears, I can simply measure it - on the screen directly.

All double edge razor blades have a fixed length and must fit snuggly in the head of the razor.

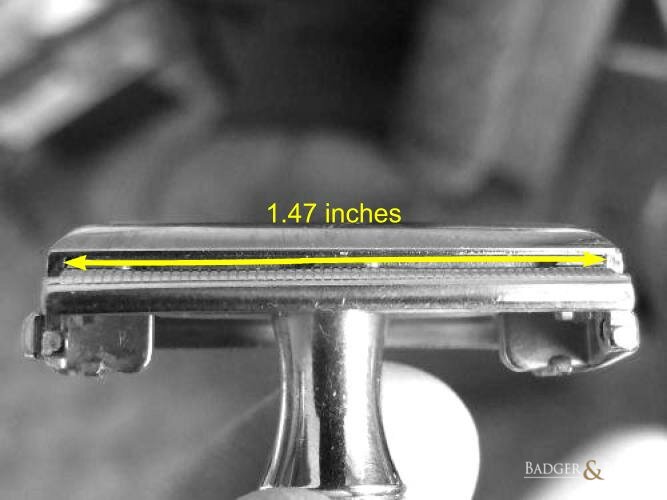

* That space is 1.47 inches long and easily visible on a picture of the razor

If the gap is, for example 1 inch wide on the screen

I can now calculate the actual gap size by the following formula:

===========================================

THE FORMULA

Actual gap = 1.47 x gap measured on screen / blade length magnified

===========================================

This is the trick that makes it possible to measure the blade gap of any safety razor.

Step 1:

Take a picture of a razor straight on

Step 2:

Magnify that picture using a computer and display it on the screen (about 30-40x)

Step 3:

Measure the gap (now on screen it is aprox 3/4 of an inch)

Step 4:

Calculate the actual gap size from the formula

===========================================

What do you need?

a) ruler [12 - 15 inches] with markings of 1/16 of an inch and perhaps a 2nd one [6 inches] with finer markings of 1/32 of an inch.

b) a digital camera that can focus on an object "close up" at a distance if less than 8 inches from the lens

c) a computer with software that can zoom in and out to resize your photo on screen

d) a calculator or basic arithmetic ability

TIME REQUIRED:

AFTER YOU'VE DONE A FEW - is a matter of only a few minutes per razor.

The first few times through the process, however, will take a little longer.

===========================================

STEP 1: Take a digital photo of the razor.

I hold the camera with my right hand and the razor in my left and found no tripod was required if there was bright daylight (or even normal artificial light available).

Take a picture of the razor WITH A BLADE INSERTED (it's easier to see) - as close to the lens as your camera can focus - so the head of the razor is as big as possible (but still remains completely contained in the picture).

Tips:

- No flash is needed. Natural daylight is best and should come from behind you.

- Try to get the camera to look directly into the gap between the blade and the safety bar.

The difference between the razor being perfectly vertical (top of blade slightly visible) or tilted slightly away from the camera (so only the blade edge is seen) makes less than a 0.001 inch difference and will not significantly effect the final results.

- rotate the handle so the corners of the blade are at right angles to the line from the lens to the razor.

- take several shots so you increase your chance of getting a good sharp "straight on" result

===========================================

STEP 2: Computer magnification

Upload your pictures from your camera to the computer and then ...

a) select the best - sharpest - shot looking "straight on" the razor gap.

c) Make NOTE of the magnification factor needed to make the head size equal to about 30 - 50" on the screen

The exact way you do this depends on your camera's resolution and your computer software.

Typically the original shot needs to be reduced to fit on the screen say by 50% where the blade length space will appear to be say 12 inches.

To get the head up to a 36" inch magnification it must be increased 3x.

This would result in a "MAGNIFICATION FACTOR" of 6x

300% / 50% = 6x

===========================================

STEP 3: Measure the (6x magnified) gap on the screen

EXAMPLE:

9/16 inch = 0.5625 = 0.563 inch

===========================================

STEP 4: Calculate the actual size of the gap.

THE FORMULA

Actual gap = 1.47 x gap measured on screen / blade length magnified

1.47 x 0.563 / 36

= 0.0229891

= .023" +/- .001 inch

If you do everything right, the "gap" result - for any given safety razor - will be between 15 and 45 (1/1000's of an inch).

That's all there is to it.

After a few values are measured & calculated an average value is established and the razors can be ranked by blade gap size.

The following instructions are revised from the earlier post

and I hope easier to follow ...

=================

IDEA !!!

=================

If we could find a few razor owners who would calculate blade gap measurements to replicate/verify each other's results we can easily create a comprehensive table of relative blade gap measurements.

Background:

Here's the trick ...

Imagine I have a photograph showing myself standing by a tree.

My image, in the picture, measures only 1 inch (head to foot).

The tree, in the picture, is 2 inches from it's highest branch to the ground.

But ...

I know my "actual" height is 6 feet.

Since the tree, in the picture, is 2 inches = 2x taller than me, in the picture,

the tree must be 2x6 feet in reality or 12 feet tall.

Now imagine that I have a photograph of the head of a razor - straght on looking "into the gap between the blade edge and the safety bar.

If I zoom in (or magnify it) by some factor I could increase the head's length on the screen to say 50 inches.

My image is now much too big to be contained entirely on the screen but if I scroll to the part of the image where the gap appears, I can simply measure it - on the screen directly.

All double edge razor blades have a fixed length and must fit snuggly in the head of the razor.

* That space is 1.47 inches long and easily visible on a picture of the razor

If the gap is, for example 1 inch wide on the screen

I can now calculate the actual gap size by the following formula:

===========================================

THE FORMULA

Actual gap = 1.47 x gap measured on screen / blade length magnified

===========================================

This is the trick that makes it possible to measure the blade gap of any safety razor.

Step 1:

Take a picture of a razor straight on

Step 2:

Magnify that picture using a computer and display it on the screen (about 30-40x)

Step 3:

Measure the gap (now on screen it is aprox 3/4 of an inch)

Step 4:

Calculate the actual gap size from the formula

===========================================

What do you need?

a) ruler [12 - 15 inches] with markings of 1/16 of an inch and perhaps a 2nd one [6 inches] with finer markings of 1/32 of an inch.

b) a digital camera that can focus on an object "close up" at a distance if less than 8 inches from the lens

c) a computer with software that can zoom in and out to resize your photo on screen

d) a calculator or basic arithmetic ability

TIME REQUIRED:

AFTER YOU'VE DONE A FEW - is a matter of only a few minutes per razor.

The first few times through the process, however, will take a little longer.

===========================================

STEP 1: Take a digital photo of the razor.

I hold the camera with my right hand and the razor in my left and found no tripod was required if there was bright daylight (or even normal artificial light available).

Take a picture of the razor WITH A BLADE INSERTED (it's easier to see) - as close to the lens as your camera can focus - so the head of the razor is as big as possible (but still remains completely contained in the picture).

Tips:

- No flash is needed. Natural daylight is best and should come from behind you.

- Try to get the camera to look directly into the gap between the blade and the safety bar.

The difference between the razor being perfectly vertical (top of blade slightly visible) or tilted slightly away from the camera (so only the blade edge is seen) makes less than a 0.001 inch difference and will not significantly effect the final results.

- rotate the handle so the corners of the blade are at right angles to the line from the lens to the razor.

- take several shots so you increase your chance of getting a good sharp "straight on" result

===========================================

STEP 2: Computer magnification

Upload your pictures from your camera to the computer and then ...

a) select the best - sharpest - shot looking "straight on" the razor gap.

c) Make NOTE of the magnification factor needed to make the head size equal to about 30 - 50" on the screen

The exact way you do this depends on your camera's resolution and your computer software.

Typically the original shot needs to be reduced to fit on the screen say by 50% where the blade length space will appear to be say 12 inches.

To get the head up to a 36" inch magnification it must be increased 3x.

This would result in a "MAGNIFICATION FACTOR" of 6x

300% / 50% = 6x

===========================================

STEP 3: Measure the (6x magnified) gap on the screen

EXAMPLE:

9/16 inch = 0.5625 = 0.563 inch

===========================================

STEP 4: Calculate the actual size of the gap.

THE FORMULA

Actual gap = 1.47 x gap measured on screen / blade length magnified

1.47 x 0.563 / 36

= 0.0229891

= .023" +/- .001 inch

If you do everything right, the "gap" result - for any given safety razor - will be between 15 and 45 (1/1000's of an inch).

That's all there is to it.

After a few values are measured & calculated an average value is established and the razors can be ranked by blade gap size.

Last edited by a moderator:

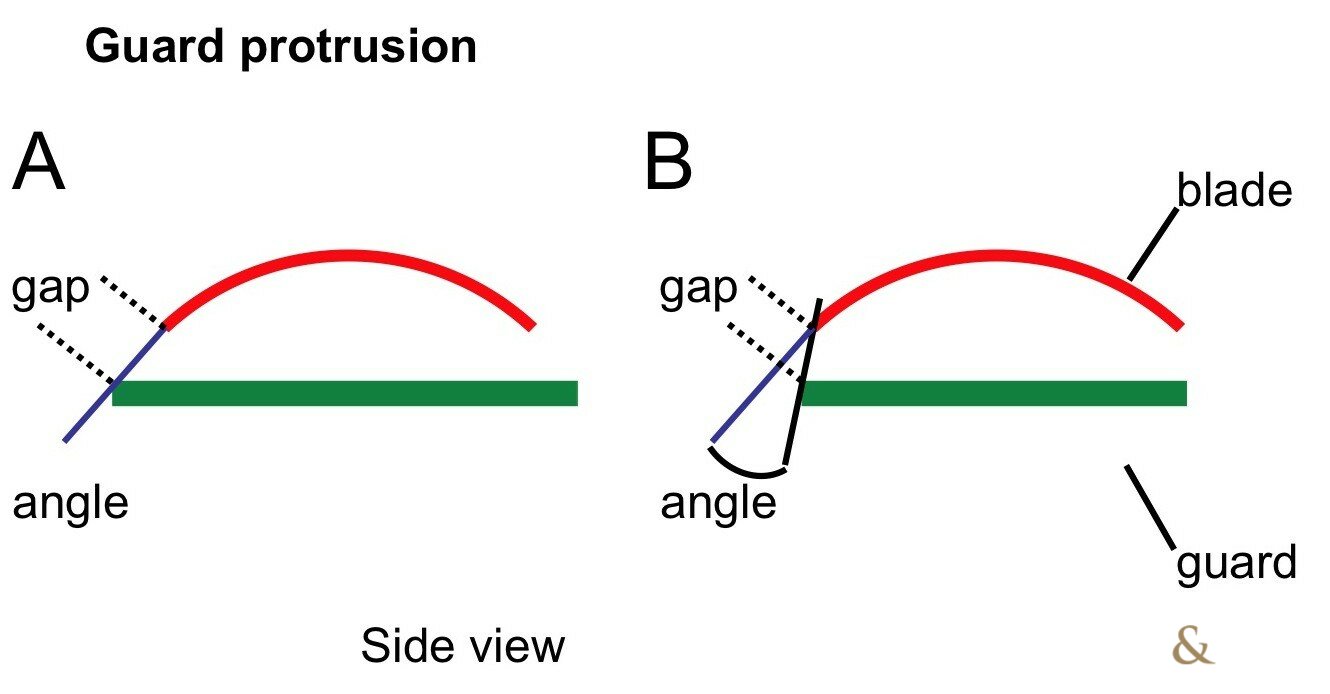

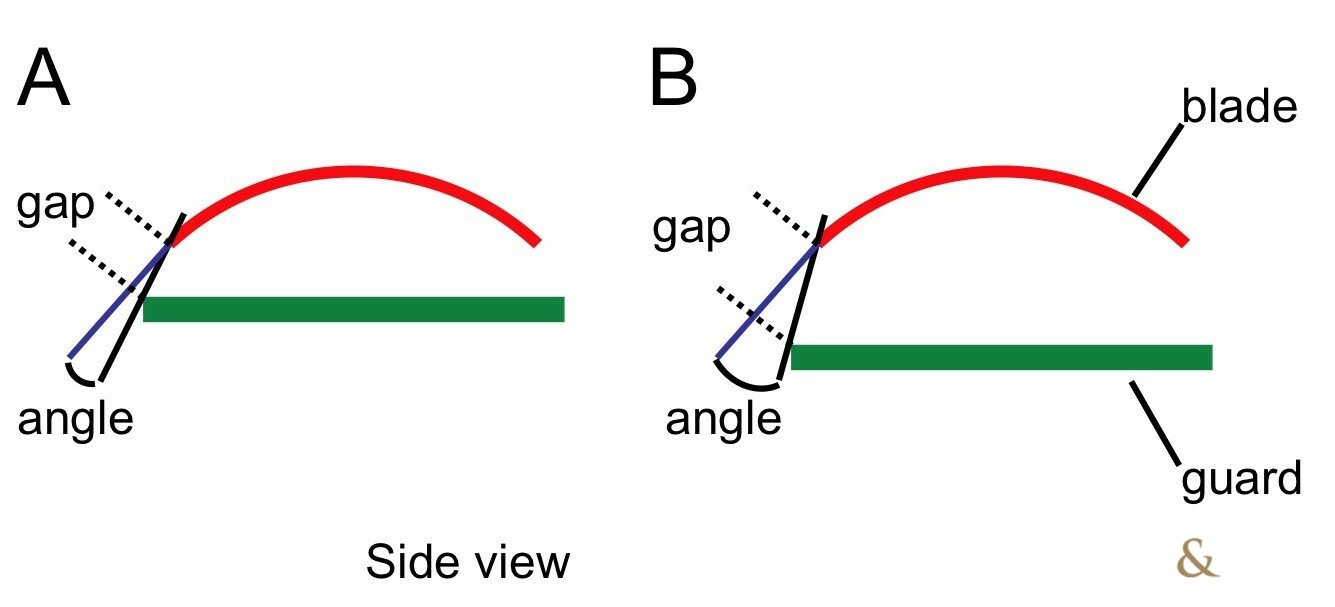

). The reason is illustrated here:

). The reason is illustrated here: