Brill! Really interesting to read your take on that video @helicopter. I thought you'd have a far better idea of what was being shown and what it all meant.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Blade Sharpness Research Project

- Thread starter helicopter

- Start date

Ha! Here's fun ...

Syed Sheharyar Ali (Treet Corporation CEO) has a personal website/blog at Syed Sheharyar Ali - https://syedsheharyarali.com - he's the grandson of Treet founder Syed Wajid Ali. I found an interesting insight into the business of razor blade making in Pakistan in his website: Razor Wars: What does Gillette’s local manufacturing decision mean for its rivals? – Syed Sheharyar Ali - https://syedsheharyarali.com/razor-wars-what-does-gillettes-local-manufacturing-decision-mean-for-its-rivals/

I love the explanantion for what happened to SuperMax: "So, what happened to Supermax? After all, it has been decades since anyone in Pakistan has shaved using a Supermax razor. According to sources familiar with the matter, Supermax was a family-owned business, and it was killed off by what often kills off family-owned businesses: a family dispute."

Haha! I'd commented above that the fall of SuperMax was worthy of a Netflix drama akin to 'Succession'.

I also found the source information for Wikipedia's statement that Treet was founded as a joint venture with American Safety Razor Corporation: Treet Corporation: Nurturing Growth, Embracing Integrity – Syed Sheharyar Ali - https://syedsheharyarali.com/treet-corporation-nurturing-growth-embracing-integrity/

... which finally gives me the answer as to why Treet (USA) had the same logo as Treet (Pakistan) although I thought it was into the 1950s when ASR acquired Treet, along with Personna & PAL rather than 1947 when Treet (Pakistan) was founded. There might be some artistic license as to when the company was actually founded and what exactly they were doing at the time. The Treet Razor Blade Company might have come into the fold after a short number of years.

Fun read, although I had to lookup what a "concomitant consonance" might be!

You all might have guessed by now, I'm a "Treet man" ... and a "Lord man". Fascinating to really lift the lid.

Syed Sheharyar Ali (Treet Corporation CEO) has a personal website/blog at Syed Sheharyar Ali - https://syedsheharyarali.com - he's the grandson of Treet founder Syed Wajid Ali. I found an interesting insight into the business of razor blade making in Pakistan in his website: Razor Wars: What does Gillette’s local manufacturing decision mean for its rivals? – Syed Sheharyar Ali - https://syedsheharyarali.com/razor-wars-what-does-gillettes-local-manufacturing-decision-mean-for-its-rivals/

I love the explanantion for what happened to SuperMax: "So, what happened to Supermax? After all, it has been decades since anyone in Pakistan has shaved using a Supermax razor. According to sources familiar with the matter, Supermax was a family-owned business, and it was killed off by what often kills off family-owned businesses: a family dispute."

Haha! I'd commented above that the fall of SuperMax was worthy of a Netflix drama akin to 'Succession'.

From the scant reading I have done about the company and its spin-offs (like RK) it's real brother vs brother stuff and worthy of a TV series like 'Succession'.

I also found the source information for Wikipedia's statement that Treet was founded as a joint venture with American Safety Razor Corporation: Treet Corporation: Nurturing Growth, Embracing Integrity – Syed Sheharyar Ali - https://syedsheharyarali.com/treet-corporation-nurturing-growth-embracing-integrity/

... which finally gives me the answer as to why Treet (USA) had the same logo as Treet (Pakistan) although I thought it was into the 1950s when ASR acquired Treet, along with Personna & PAL rather than 1947 when Treet (Pakistan) was founded. There might be some artistic license as to when the company was actually founded and what exactly they were doing at the time. The Treet Razor Blade Company might have come into the fold after a short number of years.

Fun read, although I had to lookup what a "concomitant consonance" might be!

You all might have guessed by now, I'm a "Treet man" ... and a "Lord man". Fascinating to really lift the lid.

- Thread starter

- #1,043

This is the V12 Super Platinum blade, which was made in India in January of 2023 for GreatWhite Global Private Limited, Jadavji Anchorwala Enterprise, Indian and UK companies that are not manufacturers. I am not sure who actually made it, but it is of good quality, standard 100 micron thickness, mild in sharpness, with very good durability and consistency. I only paid 79 cents for the tuck of ten at The Razor Company.

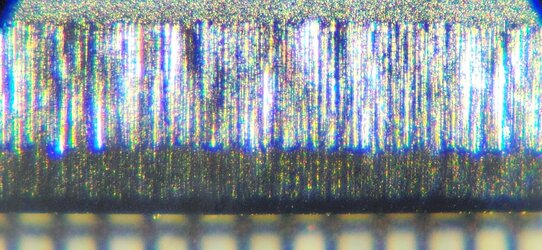

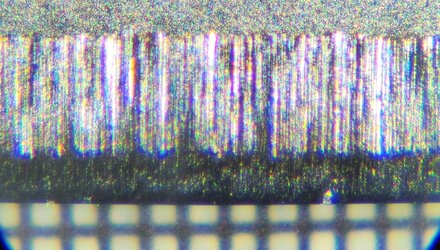

It is a three stage grind with metallic coating. The primary grind abrasives are coarse and crude, but not in any way that should effect the apex.

After the test, the edge is in excellent condition, with a little bit of small chipping, and some coating wear.

P6 and P12 measurements have higher standard deviation, so the true curve is probably closer to the standard platinum coated J-shape.

It is quite mild, and quality of my example is excellent.

Blade Sharpness Test Index

It is a three stage grind with metallic coating. The primary grind abrasives are coarse and crude, but not in any way that should effect the apex.

After the test, the edge is in excellent condition, with a little bit of small chipping, and some coating wear.

| Date | 20-Nov-2024 | Blade Thickness, mm | 0.100 | ||

| Blade | GreatWhite GPL | V12 | Super Platinum | India | 15-Jan-2023 |

| Wear on Edge | 0 | 3 | 6 | 9 | 12 |

| Edges Measured | Bottom / Top | Bottom / Top | Bottom / Top | Bottom / Top | Bottom / Top |

| Measurement Medium | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 |

| Dulling Substrate | New | Paper | Paper | Paper | Paper |

| Measurements | 20 | 20 | 20 | 20 | 20 |

| Adj. Std. Dev. | 7 | 9 | 12 | 8 | 12 |

| Median F (g) | 63.5 | 60 | 63 | 63.5 | 63 |

| Mean F (g) Top | 64 | 65 | 70 | 68 | 69 |

| Mean F (g) Bottom | 64 | 58 | 62 | 62 | 63 |

| Mean F (g) | 64 | 61 | 66 | 65 | 66 |

| BESS Adj. Factor | 1.22 | 1.22 | 1.22 | 1.22 | 1.22 |

| Avg. Adj. F (g) Top | 78 | 79 | 86 | 82 | 84 |

| Avg. Adj. F (g) Bottom | 78 | 70 | 76 | 76 | 76 |

| Median Adj. F (g) | 77 | 73 | 77 | 77 | 77 |

| Mean Adj. F (g) | 78 | 75 | 81 | 79 | 80 |

P6 and P12 measurements have higher standard deviation, so the true curve is probably closer to the standard platinum coated J-shape.

It is quite mild, and quality of my example is excellent.

Blade Sharpness Test Index

Attachments

- Thread starter

- #1,044

This is the Jiangxi Xirui Rhinoceros XR red tall A77 blade. Unlike the 90 micron short version of this blade tested previously, this one is a standard 100 micron blade.

It is very durable and consistent, and unlike the short and thin version, this one is quite mild in sharpness. As I mentioned previously, my testing procedure doesn't reflect the fact that these blades should see less wear than blades with shorter edges since each millimeter of edge needs to do less work per pass and per shave. The paper cuts push the entire edge through stacked sheets of paper, so the longer edge is doing a proportional (to its length) amount of work. In practice, it should be very durable and consistent.

The three stage grind and metallic coating are done very nicely with good abrasives and even transitions.

The edge held up very well to the testing procedure. The failure mode of the steel is small chipping, typical of high quality razor steel.

It is the mildest A77 blade tested so far.

It is not quite the mildest blade from an A77 blade producer. One of the cloud DE blades was even milder.

Due to the fact that it will be used in shavettes, it should feel fairly sharp subjectively, anyway, but it might give someone like me problems going against the grain on spots with thick and coarse hair.

Blade Sharpness Test Index

It is very durable and consistent, and unlike the short and thin version, this one is quite mild in sharpness. As I mentioned previously, my testing procedure doesn't reflect the fact that these blades should see less wear than blades with shorter edges since each millimeter of edge needs to do less work per pass and per shave. The paper cuts push the entire edge through stacked sheets of paper, so the longer edge is doing a proportional (to its length) amount of work. In practice, it should be very durable and consistent.

The three stage grind and metallic coating are done very nicely with good abrasives and even transitions.

The edge held up very well to the testing procedure. The failure mode of the steel is small chipping, typical of high quality razor steel.

It is the mildest A77 blade tested so far.

It is not quite the mildest blade from an A77 blade producer. One of the cloud DE blades was even milder.

| Date | 20-Nov-2024 | Blade Thickness, mm | 0.100 | ||

| Blade | Jiangxi Xirui | Rhinoceros XR | A77 1.7 Red | China | 1-Jan-2024 |

| Wear on Edge | 0 | 3 | 6 | 9 | 12 |

| Edges Measured | Bottom / Top | Bottom / Top | Bottom / Top | Bottom / Top | Bottom / Top |

| Measurement Medium | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 |

| Dulling Substrate | New | Paper | Paper | Paper | Paper |

| Measurements | 20 | 20 | 20 | 20 | 20 |

| Adj. Std. Dev. | 5 | 7 | 6 | 7 | 8 |

| Median F (g) | 66 | 65 | 63 | 65 | 67.5 |

| Mean F (g) Top | 68 | 63 | 63 | 68 | 67 |

| Mean F (g) Bottom | 65 | 66 | 65 | 67 | 69 |

| Mean F (g) | 66 | 64 | 64 | 68 | 68 |

| BESS Adj. Factor | 1.22 | 1.22 | 1.22 | 1.22 | 1.22 |

| Avg. Adj. F (g) Top | 83 | 76 | 77 | 82 | 81 |

| Avg. Adj. F (g) Bottom | 79 | 81 | 79 | 82 | 84 |

| Median Adj. F (g) | 81 | 79 | 77 | 79 | 82 |

| Mean Adj. F (g) | 81 | 79 | 78 | 82 | 83 |

Due to the fact that it will be used in shavettes, it should feel fairly sharp subjectively, anyway, but it might give someone like me problems going against the grain on spots with thick and coarse hair.

Blade Sharpness Test Index

This is the Jiangxi Xirui Rhinoceros XR red tall A77 blade. Unlike the 90 micron short version of this blade tested previously, this one is a standard 100 micron blade.

The packing is different, but I think this might be the A77 Rhinocerous blade I used, not the one you reviewed previously. Mine were tall and looked like this:

That explains why I was surprised at the sharpness on the earlier review - it wasn't the same blade! The results here seem more consistent with my experience and you are right - not sharp enough for ATG for me.

- Thread starter

- #1,046

This is Sotraco's Lord Premium New Platinum Super Stainless plastic tuck blade. It is thin, mild, and has typical durability and consistency. Relative to most Sotraco blades, including the regular white paper tuck Lord Platinum I tested, it is more durable and consistent.

It doesn't have a date code. The stenciling and blade wrapper match the white paper tuck Lord New Platinum.

The grind is done with fine but uneven abrasives. There are scratches from the secondary grind near the bevel, and we do see some spots with moderate local failure in the testing.

The steel is in good condition after the test with a failure mode of small chipping typical of high quality razor blade steel. We don't see that with most Sotraco blades. It is possible this one is done with a different alloy.

Performance doesn't closely match any of the other Sotraco blades tested. It is milder, more durable, and more consistent than products from this company tend to be.

It is pretty well balanced, so there is a decent chance it is reasonably close to nominal specification.

It is mild with typical durability and consistency.

I don't really trust this company to produce anything resembling their nominal specifications, so it is hard to say if the performance of this one is representative or intentional. It is possible they used a better steel. It is possible they were more careful with maintaining belts. It is also possible that it is supposed to be the same as the other Lord Platinum except for the packaging and the difference in performance we see is just inconsistency in the product.

Blade Sharpness Test Index

It doesn't have a date code. The stenciling and blade wrapper match the white paper tuck Lord New Platinum.

The grind is done with fine but uneven abrasives. There are scratches from the secondary grind near the bevel, and we do see some spots with moderate local failure in the testing.

The steel is in good condition after the test with a failure mode of small chipping typical of high quality razor blade steel. We don't see that with most Sotraco blades. It is possible this one is done with a different alloy.

Performance doesn't closely match any of the other Sotraco blades tested. It is milder, more durable, and more consistent than products from this company tend to be.

It is pretty well balanced, so there is a decent chance it is reasonably close to nominal specification.

| Date | 20-Nov-2024 | Blade Thickness, mm | 0.090 | ||

| Blade | Sotraco | Lord | Platinum Premium | Egypt | 1-Jan-2024 |

| Wear on Edge | 0 | 3 | 6 | 9 | 12 |

| Edges Measured | Top / Bottom | Top / Bottom | Top / Bottom | Top / Bottom | Top / Bottom |

| Measurement Medium | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 |

| Dulling Substrate | Paper | Paper | Paper | New | Paper |

| Measurements | 20 | 20 | 20 | 20 | 20 |

| Adj. Std. Dev. | 9 | 7 | 14 | 13 | 25 |

| Median F (g) | 60.5 | 59 | 60 | 65 | 62.5 |

| Mean F (g) Top | 60 | 60 | 63 | 67 | 82 |

| Mean F (g) Bottom | 65 | 60 | 63 | 65 | 60 |

| Mean F (g) | 62 | 60 | 63 | 66 | 71 |

| BESS Adj. Factor | 1.22 | 1.22 | 1.22 | 1.22 | 1.22 |

| Avg. Adj. F (g) Top | 73 | 73 | 76 | 81 | 101 |

| Avg. Adj. F (g) Bottom | 79 | 73 | 77 | 80 | 73 |

| Median Adj. F (g) | 74 | 72 | 73 | 79 | 76 |

| Mean Adj. F (g) | 76 | 73 | 76 | 81 | 87 |

It is mild with typical durability and consistency.

I don't really trust this company to produce anything resembling their nominal specifications, so it is hard to say if the performance of this one is representative or intentional. It is possible they used a better steel. It is possible they were more careful with maintaining belts. It is also possible that it is supposed to be the same as the other Lord Platinum except for the packaging and the difference in performance we see is just inconsistency in the product.

Blade Sharpness Test Index

Last edited:

I think the engineering term for this is "less sh*tty."It is milder, more durable, and more consistent than products from this company tend to be.

- Thread starter

- #1,048

This is the MERS Razor Works (UK) Super Shave X Platinum blade, which is a private label Chinese blade. It is a thin blade, mild in sharpness, with fair balance, and poor durability and consistency.

The graphic design is fairly generic, which suits this blade. It does have a date code, which might be the only good thing we see here.

The three stage grind is done with typical abrasives. There are some scratches from the primary grind near the apex, but they aren't the only places where the edge shows poor performance.

The failure mode of the steel is lots of medium chipping, and some medium denting. If this is Sandvik steel as advertised, then they didn't get the heat treatment right.

I think we can skip the special summary for this one. It's not like anyone is going to want to look for an OEM version of it anyway.

It's not terrible, but it also isn't good.

Blade Sharpness Test Index

The graphic design is fairly generic, which suits this blade. It does have a date code, which might be the only good thing we see here.

The three stage grind is done with typical abrasives. There are some scratches from the primary grind near the apex, but they aren't the only places where the edge shows poor performance.

The failure mode of the steel is lots of medium chipping, and some medium denting. If this is Sandvik steel as advertised, then they didn't get the heat treatment right.

I think we can skip the special summary for this one. It's not like anyone is going to want to look for an OEM version of it anyway.

| Date | 20-Nov-2024 | Blade Thickness, mm | 0.090 | ||

| Blade | MERS | Super Shave X | Platinum | China | 20-May-2020 |

| Wear on Edge | 0 | 3 | 6 | 9 | 12 |

| Edges Measured | Top / Bottom | Top / Bottom | Top / Bottom | Top / Bottom | Top / Bottom |

| Measurement Medium | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 |

| Dulling Substrate | Paper | Paper | Paper | New | Paper |

| Measurements | 20 | 20 | 20 | 20 | 20 |

| Adj. Std. Dev. | 11 | 22 | 17 | 21 | 21 |

| Median F (g) | 65.5 | 71 | 79.5 | 89.5 | 94 |

| Mean F (g) Top | 61 | 85 | 90 | 101 | 104 |

| Mean F (g) Bottom | 68 | 63 | 71 | 81 | 85 |

| Mean F (g) | 65 | 74 | 80 | 91 | 94 |

| BESS Adj. Factor | 1.22 | 1.22 | 1.22 | 1.22 | 1.22 |

| Avg. Adj. F (g) Top | 75 | 104 | 109 | 123 | 127 |

| Avg. Adj. F (g) Bottom | 83 | 77 | 86 | 99 | 103 |

| Median Adj. F (g) | 80 | 86 | 97 | 109 | 115 |

| Mean Adj. F (g) | 79 | 90 | 98 | 111 | 115 |

It's not terrible, but it also isn't good.

Blade Sharpness Test Index

- Thread starter

- #1,049

This is Supermax's Zorrik Super Platinum blade, which is a mild extra-thin 85 micron blade with surprisingly typical durability and consistency, partially attributable to a persistent and impactful platinum based metallic coating.

It has a date code, which I like to see. This blade also comes with some free samples of the Super-Max branded Supermax-Stainless blade. The free sample is something we see when a manufacturer wants us to consider another one of their products. Often, it means the company is planning to drop an existing item, and they want customers to try one of their ongoing items so they don't consider a competitor's product as a replacement. I have seen this with Schick and Gillette cartridges when they are phasing out a cheaper and older version that is compatible with the same handle. I measured both of these, and included both in the charts here, so the Super-Max Stainless is up next for a summary report.

It is a flap tuck with some useful and unambiguous information printed on it; these were manufactured by Supermax Personal Care Private Limited, Thane, a contiguous suburb of Mumbai. That means these ones are gone now, because that plant closed in lat 2022.

It is a three stage grind with coarse and uneven scratches and transitions.

The failure mode of the steel is denting. It is an interesting blade with its extra-thin steel and durable coating.

The standard deviation climbs a good amount. The steel is wearing out before the coating, so we have local spots with higher and lower sharpness as the blade wears. This happens to some extent with nearly every coated blade, but the combination of thin but tough steel, coarse grind, and a durable coating here make it more impactful. I think this blade will actually change and feel quite different as it wears, even as average sharpness is fairly consistent. You can also see how from P3-P6, median force drops as average force climbs.

For an enthusiast who likes mild blades, and has already tried dozens of different blades, this one is a little more interesting than most, due to the unusual combination of design decisions. It doesn't really do anything especially well, though.

Blade Sharpness Test Index

It has a date code, which I like to see. This blade also comes with some free samples of the Super-Max branded Supermax-Stainless blade. The free sample is something we see when a manufacturer wants us to consider another one of their products. Often, it means the company is planning to drop an existing item, and they want customers to try one of their ongoing items so they don't consider a competitor's product as a replacement. I have seen this with Schick and Gillette cartridges when they are phasing out a cheaper and older version that is compatible with the same handle. I measured both of these, and included both in the charts here, so the Super-Max Stainless is up next for a summary report.

It is a flap tuck with some useful and unambiguous information printed on it; these were manufactured by Supermax Personal Care Private Limited, Thane, a contiguous suburb of Mumbai. That means these ones are gone now, because that plant closed in lat 2022.

It is a three stage grind with coarse and uneven scratches and transitions.

The failure mode of the steel is denting. It is an interesting blade with its extra-thin steel and durable coating.

The standard deviation climbs a good amount. The steel is wearing out before the coating, so we have local spots with higher and lower sharpness as the blade wears. This happens to some extent with nearly every coated blade, but the combination of thin but tough steel, coarse grind, and a durable coating here make it more impactful. I think this blade will actually change and feel quite different as it wears, even as average sharpness is fairly consistent. You can also see how from P3-P6, median force drops as average force climbs.

| Date | 21-Nov-2024 | Blade Thickness, mm | 0.085 | ||

| Blade | Supermax | Zorrik | Super Platinum | India | 1-Apr-2022 |

| Wear on Edge | 0 | 3 | 6 | 9 | 12 |

| Edges Measured | Top / Bottom | Top / Bottom | Top / Bottom | Top / Bottom | Top / Bottom |

| Measurement Medium | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 |

| Dulling Substrate | New | Paper | Paper | Paper | Paper |

| Measurements | 20 | 20 | 20 | 20 | 20 |

| Adj. Std. Dev. | 5 | 6 | 9 | 17 | 15 |

| Median F (g) | 69 | 62 | 60 | 65.5 | 69 |

| Mean F (g) Top | 70 | 62 | 64 | 67 | 78 |

| Mean F (g) Bottom | 69 | 61 | 61 | 66 | 66 |

| Mean F (g) | 70 | 61 | 62 | 66 | 72 |

| BESS Adj. Factor | 1.22 | 1.22 | 1.22 | 1.22 | 1.22 |

| Avg. Adj. F (g) Top | 86 | 76 | 78 | 81 | 95 |

| Avg. Adj. F (g) Bottom | 84 | 74 | 74 | 80 | 81 |

| Median Adj. F (g) | 84 | 75 | 73 | 80 | 84 |

| Mean Adj. F (g) | 85 | 75 | 76 | 81 | 88 |

For an enthusiast who likes mild blades, and has already tried dozens of different blades, this one is a little more interesting than most, due to the unusual combination of design decisions. It doesn't really do anything especially well, though.

Blade Sharpness Test Index

- Thread starter

- #1,050

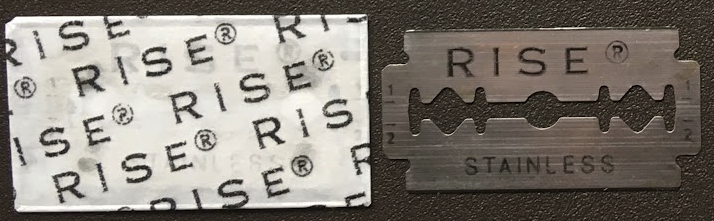

This is the Super-Max Stainless blade, which Supermax included with the Zorrik Super Platinum I measured in the previous test. You can look there for pictures of the blade and packaging and the standard carts, as I measured them together and included this with this one in that report.

This thin 90 micron blade is moderately sharp, with good initial consistency and balance, and typical durability. There is some kind of coating that has a small impact on performance, though it may just be polymer. The primary grind looks a little crude and coarse, but the secondary grind and honing are fairly typical.

The failure mode is some small chipping typical of good razor steel.

The Tigaksha RK Henson blade has very similar performance. The grind of that blade was much more even and of better quality than this one, but the transitions and grit sizes look about the same. That blade is also a raw Stainless spec 90 micron blade. Due to this, and some sort of Supermax location at the Tigaksha plant's campus on Google Maps, I suspect the two might be related. If you were sad to see the discontinuation of this blade, I would encourage you to take a look at the Tigaksha RK Henson Stainless blade.

I wasn't keeping a library of used test blades yet when I measured the RK Henson, but here is a scalable image of a new one. It is the same idea, just better abrasives.

I was skeptical of the claim it was "Specifically Designed for the Henson AL13," and now I am even more skeptical. I will concede that I haven't found another current Tigaksha blade of the same specification, at least not yet.

Blade Sharpness Test Index

This thin 90 micron blade is moderately sharp, with good initial consistency and balance, and typical durability. There is some kind of coating that has a small impact on performance, though it may just be polymer. The primary grind looks a little crude and coarse, but the secondary grind and honing are fairly typical.

The failure mode is some small chipping typical of good razor steel.

The Tigaksha RK Henson blade has very similar performance. The grind of that blade was much more even and of better quality than this one, but the transitions and grit sizes look about the same. That blade is also a raw Stainless spec 90 micron blade. Due to this, and some sort of Supermax location at the Tigaksha plant's campus on Google Maps, I suspect the two might be related. If you were sad to see the discontinuation of this blade, I would encourage you to take a look at the Tigaksha RK Henson Stainless blade.

I wasn't keeping a library of used test blades yet when I measured the RK Henson, but here is a scalable image of a new one. It is the same idea, just better abrasives.

I was skeptical of the claim it was "Specifically Designed for the Henson AL13," and now I am even more skeptical. I will concede that I haven't found another current Tigaksha blade of the same specification, at least not yet.

| Date | 21-Nov-2024 | Blade Thickness, mm | 0.090 | ||

| Blade | Supermax | Supermax | Stainless | India | 1-Apr-2022 |

| Wear on Edge | 0 | 3 | 6 | 9 | 12 |

| Edges Measured | Top / Bottom | Top / Bottom | Top / Bottom | Top / Bottom | Top / Bottom |

| Measurement Medium | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 |

| Dulling Substrate | New | Paper | Paper | Paper | Paper |

| Measurements | 20 | 20 | 20 | 20 | 20 |

| Adj. Std. Dev. | 7 | 7 | 14 | 14 | 16 |

| Median F (g) | 57.5 | 57 | 63 | 60.5 | 64 |

| Mean F (g) Top | 60 | 58 | 72 | 71 | 71 |

| Mean F (g) Bottom | 56 | 58 | 59 | 60 | 65 |

| Mean F (g) | 58 | 58 | 65 | 66 | 68 |

| BESS Adj. Factor | 1.22 | 1.22 | 1.22 | 1.22 | 1.22 |

| Avg. Adj. F (g) Top | 74 | 71 | 87 | 86 | 87 |

| Avg. Adj. F (g) Bottom | 68 | 70 | 72 | 74 | 80 |

| Median Adj. F (g) | 70 | 70 | 77 | 74 | 78 |

| Mean Adj. F (g) | 71 | 70 | 80 | 80 | 83 |

Blade Sharpness Test Index

- Thread starter

- #1,051

Before anyone asks...

No manufacturing location is specified on the Vidyut Super-Max Platinum

No manufacturing location is specified on the Vidyut Super-Max Platinum

- Thread starter

- #1,052

This is the Vidyut Zorrik Super Stainless blade made in India for Super-Max Limited, UK. It is a thin a crudely ground blade, very mild in sharpness with poor durability and consistency.

It doesn't have a date code.

Similar to the other Indian Super-Max UK blade, there is a tuck flap, but we don't get a specific manufacturing location.

It is a crude and blunt three stage grind, with short bevels, large uneven scratches, uneven transitions, and large scratches near the apex.

The failure mode of the steel is lots of medium chipping, which we usually see with thin steel or poor and fair quality.

I tried two of them looking for a good one, but they are both like this, and based on microscopic inspection of the grind, I think they came off the production line like this.

Blade Sharpness Test Index

It doesn't have a date code.

Similar to the other Indian Super-Max UK blade, there is a tuck flap, but we don't get a specific manufacturing location.

It is a crude and blunt three stage grind, with short bevels, large uneven scratches, uneven transitions, and large scratches near the apex.

The failure mode of the steel is lots of medium chipping, which we usually see with thin steel or poor and fair quality.

I tried two of them looking for a good one, but they are both like this, and based on microscopic inspection of the grind, I think they came off the production line like this.

| Date | 21-Nov-2024 | Blade Thickness, mm | 0.090 | ||

| Blade | Super-Max UK | Vidyut | Zorikk Super Stainless | India | 1-Jan-2024 |

| Wear on Edge | 0 | 3 | 6 | 9 | 12 |

| Edges Measured | Bottom / Top | Bottom / Top | Bottom / Top | Bottom / Top | Bottom / Top |

| Measurement Medium | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 |

| Dulling Substrate | New | Paper | Paper | Paper | Paper |

| Measurements | 20 | 20 | 20 | 20 | 20 |

| Adj. Std. Dev. | 22 | 30 | 26 | 29 | 21 |

| Median F (g) | 66.5 | 77 | 84 | 93 | 114.5 |

| Mean F (g) Top | 80 | 100 | 105 | 114 | 121 |

| Mean F (g) Bottom | 68 | 66 | 76 | 80 | 98 |

| Mean F (g) | 74 | 83 | 91 | 97 | 109 |

| BESS Adj. Factor | 1.22 | 1.22 | 1.22 | 1.22 | 1.22 |

| Avg. Adj. F (g) Top | 97 | 122 | 128 | 139 | 148 |

| Avg. Adj. F (g) Bottom | 83 | 81 | 93 | 97 | 119 |

| Median Adj. F (g) | 81 | 94 | 103 | 113 | 140 |

| Mean Adj. F (g) | 90 | 101 | 110 | 118 | 133 |

Blade Sharpness Test Index

Enjoying the SuperMax tests ... more, please!

I reckon the Vidyut/SuperMax Stainless you tested above (included with the Zorrik Super Platinums) was from the burgundy/yellow pack:

I also think it's a fair assumption that these three are all the same base blade - the blue/coral pack was the global export for a good while, then the V/blue pack with its Wizamet stylings! Burgundy/yellow domestic market. Clearly, look and feel are very important for the Indian subcontinent market.

I rather formed the opinion that the other generation of Super Stainless were all the same - the green/yellow, blue and blue+ ... and the off-brand Ninja. If you have these blades it would be really fun to see if they're all in the same ballpark ... and in the same ballpark as the stainless blades with the cursive Super-Max branding.

I reckon the Vidyut/SuperMax Stainless you tested above (included with the Zorrik Super Platinums) was from the burgundy/yellow pack:

I also think it's a fair assumption that these three are all the same base blade - the blue/coral pack was the global export for a good while, then the V/blue pack with its Wizamet stylings! Burgundy/yellow domestic market. Clearly, look and feel are very important for the Indian subcontinent market.

I rather formed the opinion that the other generation of Super Stainless were all the same - the green/yellow, blue and blue+ ... and the off-brand Ninja. If you have these blades it would be really fun to see if they're all in the same ballpark ... and in the same ballpark as the stainless blades with the cursive Super-Max branding.

Attachments

I concur ...This is Supermax's Zorrik Super Platinum blade, which is a mild extra-thin 85 micron blade with surprisingly typical durability and consistency, partially attributable to a persistent and impactful platinum based metallic coating.

It has a date code, which I like to see. This blade also comes with some free samples of the Super-Max branded Supermax-Stainless blade. The free sample is something we see when a manufacturer wants us to consider another one of their products. Often, it means the company is planning to drop an existing item, and they want customers to try one of their ongoing items so they don't consider a competitor's product as a replacement. I have seen this with Schick and Gillette cartridges when they are phasing out a cheaper and older version that is compatible with the same handle. I measured both of these, and included both in the charts here, so the Super-Max Stainless is up next for a summary report.

View attachment 1947330View attachment 1947331

It is a flap tuck with some useful and unambiguous information printed on it; these were manufactured by Supermax Personal Care Private Limited, Thane, a contiguous suburb of Mumbai. That means these ones are gone now, because that plant closed in lat 2022.

View attachment 1947332

It is a three stage grind with coarse and uneven scratches and transitions.

View attachment 1947333

The failure mode of the steel is denting. It is an interesting blade with its extra-thin steel and durable coating.

View attachment 1947334

View attachment 1947341

The standard deviation climbs a good amount. The steel is wearing out before the coating, so we have local spots with higher and lower sharpness as the blade wears. This happens to some extent with nearly every coated blade, but the combination of thin but tough steel, coarse grind, and a durable coating here make it more impactful. I think this blade will actually change and feel quite different as it wears, even as average sharpness is fairly consistent. You can also see how from P3-P6, median force drops as average force climbs.

Date 21-Nov-2024

Blade Thickness, mm 0.085 Blade Supermax Zorrik Super Platinum India 1-Apr-2022 Wear on Edge 0 3 6 9 12 Edges Measured Top / Bottom Top / Bottom Top / Bottom Top / Bottom Top / Bottom Measurement Medium Stren 6 .22 Stren 6 .22 Stren 6 .22 Stren 6 .22 Stren 6 .22 Dulling Substrate New Paper Paper Paper Paper Measurements 20 20 20 20 20 Adj. Std. Dev. 5 6 9 17 15 Median F (g) 69 62 60 65.5 69 Mean F (g) Top 70 62 64 67 78 Mean F (g) Bottom 69 61 61 66 66 Mean F (g) 70 61 62 66 72 BESS Adj. Factor 1.22 1.22 1.22 1.22 1.22 Avg. Adj. F (g) Top 86 76 78 81 95 Avg. Adj. F (g) Bottom 84 74 74 80 81 Median Adj. F (g) 84 75 73 80 84 Mean Adj. F (g) 85 75 76 81 88

View attachment 1947342 View attachment 1947343

For an enthusiast who likes mild blades, and has already tried dozens of different blades, this one is a little more interesting than most, due to the unusual combination of design decisions. It doesn't really do anything especially well, though.

Blade Sharpness Test Index

It's certainly "good enough" giving a smooth and clean shave, but nothing immediately obvious to latch onto that might warrant a bulk purchase.

To my face, this blade was also wrapped in the following brandings:

... to my face, these fell considerably short of the global market SuperMax Blue Diamond and the popular Diamond Edge platinum blades (which I'd say are the same as each other).

- Thread starter

- #1,055

This is the Super-Max Super Stainless Blue blade, which was made for Super-Max Ltd., London, UK. It is an extra-thin 85 micron blade with a blunt grind and the poor durability and consistency I would expect from that combination of design decisions. It is crudely ground. The balance is good enough that you shouldn't notice it.

The security hologram on the tuck has a Vidyut logo on it.

The three stage grind is crude, with coarse and uneven scratches including some large scratches bleeding into the tertiary bevel.

The failure mode of the steel is lots of medium chipping.

It is dull, and as durable and consistent as it could be with a blunt edge and 85 micron stock.

Both edges had poor performance. I started with one that was even worse, and re-started the procedure with a fresh blade part-way through the first set.

I think this is a blade we can all live without.

Blade Sharpness Test Index

The security hologram on the tuck has a Vidyut logo on it.

The three stage grind is crude, with coarse and uneven scratches including some large scratches bleeding into the tertiary bevel.

The failure mode of the steel is lots of medium chipping.

It is dull, and as durable and consistent as it could be with a blunt edge and 85 micron stock.

Both edges had poor performance. I started with one that was even worse, and re-started the procedure with a fresh blade part-way through the first set.

| Date | 22-Nov-2024 | Blade Thickness, mm | 0.085 | ||

| Blade | Super-Max UK | Super-Max | Super Stainless Blue | India | 1-Jan-2022 |

| Wear on Edge | 0 | 3 | 6 | 9 | 12 |

| Edges Measured | Bottom / Top | Bottom / Top | Bottom / Top | Bottom / Top | Bottom / Top |

| Measurement Medium | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 |

| Dulling Substrate | New | Paper | Paper | Paper | Paper |

| Measurements | 20 | 20 | 20 | 20 | 20 |

| Adj. Std. Dev. | 21 | 23 | 27 | 23 | 21 |

| Median F (g) | 78.5 | 81 | 103 | 107.5 | 122.5 |

| Mean F (g) Top | 89 | 86 | 110 | 117 | 124 |

| Mean F (g) Bottom | 80 | 84 | 86 | 95 | 98 |

| Mean F (g) | 84 | 85 | 98 | 106 | 111 |

| BESS Adj. Factor | 1.22 | 1.22 | 1.22 | 1.22 | 1.22 |

| Avg. Adj. F (g) Top | 109 | 105 | 134 | 142 | 151 |

| Avg. Adj. F (g) Bottom | 97 | 103 | 105 | 116 | 120 |

| Median Adj. F (g) | 96 | 98 | 126 | 131 | 149 |

| Mean Adj. F (g) | 103 | 104 | 120 | 129 | 136 |

I think this is a blade we can all live without.

Blade Sharpness Test Index

This is the Super-Max Super Stainless Blue blade, which was made for Super-Max Ltd., London, UK. It is an extra-thin 85 micron blade with a blunt grind and the poor durability and consistency I would expect from that combination of design decisions. It is crudely ground. The balance is good enough that you shouldn't notice it.

I think this is a blade we can all live without.

My post-shave notes simply said "Not up to the regular SuperMax Super/Stainless" by which I meant the trio of blades I showed abov - the Economy, the coral/blue pack and the Wizamet-styled blue pack.

There is a Blue+ (which RBC have in their catalogue) but I've not tried it.

- Thread starter

- #1,057

This is the Topaz Stainless blade from Malhotra IPL, which is one of the RK/Supermax family businesses. This one doesn't specify a production location, but it is an Indian blade. It is thin, crudely ground, blunt, mild in sharpness, and quite durable and consistent.

It looks like an unusual polymer coating. The three stage grind is crude and blunt.

After testing, the steel is in good condition with a failure mode of small chipping. The heavy polymer coating is still visible near the primary-secondary grind transition.

Performance doesn't resemble any of the other blades that might be related to it.

Blade Sharpness Test Index

It looks like an unusual polymer coating. The three stage grind is crude and blunt.

After testing, the steel is in good condition with a failure mode of small chipping. The heavy polymer coating is still visible near the primary-secondary grind transition.

Performance doesn't resemble any of the other blades that might be related to it.

| Date | 22-Nov-2024 | Blade Thickness, mm | 0.090 | ||

| Blade | Malhotra Int'l | Topaz | Stainless Micronised | India | 1-Jun-2022 |

| Wear on Edge | 0 | 3 | 6 | 9 | 12 |

| Edges Measured | Bottom / Top | Bottom / Top | Bottom / Top | Bottom / Top | Bottom / Top |

| Measurement Medium | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 |

| Dulling Substrate | New | Paper | Paper | Paper | Paper |

| Measurements | 20 | 20 | 20 | 20 | 20 |

| Adj. Std. Dev. | 7 | 8 | 10 | 14 | 12 |

| Median F (g) | 78 | 76 | 76 | 72.5 | 82 |

| Mean F (g) Top | 77 | 80 | 82 | 87 | 87 |

| Mean F (g) Bottom | 77 | 75 | 74 | 70 | 75 |

| Mean F (g) | 77 | 77 | 78 | 78 | 81 |

| BESS Adj. Factor | 1.22 | 1.22 | 1.22 | 1.22 | 1.22 |

| Avg. Adj. F (g) Top | 94 | 97 | 100 | 106 | 107 |

| Avg. Adj. F (g) Bottom | 94 | 92 | 90 | 85 | 91 |

| Median Adj. F (g) | 95 | 93 | 93 | 88 | 100 |

| Mean Adj. F (g) | 94 | 94 | 95 | 95 | 99 |

Blade Sharpness Test Index

- Thread starter

- #1,058

This is the Dollar Platinum blade, which was made for distribution in Pakistan by the Middlesex, UK Super-Max Ltd. It is a standard 100 micron blade, mild in sharpness, with typical durability, consistency, and balance.

It is a typical three stage grind with a visible metallic coating half way up the tertiary bevel. The grind looks similar to RK New Chromium.

The steel is in good condition after the test, with some small chipping at the edge.

It is mild in sharpness with typical durability and consistency. The impact of the metallic coating is less than we typically see with platinum based coatings, but it is in the right range for mild platinum or chrome. Performance of this 100 micron blade is very similar to the 90 micron RK New Chromium and the 95 micron Vidyut Super-Max Platinum. Having done absolutely no additional sleuthing for this one, I am guessing it is a Tigaksha blade of the same grind and coating as the RK New Chromium.

Blade Sharpness Test Index

It is a typical three stage grind with a visible metallic coating half way up the tertiary bevel. The grind looks similar to RK New Chromium.

The steel is in good condition after the test, with some small chipping at the edge.

It is mild in sharpness with typical durability and consistency. The impact of the metallic coating is less than we typically see with platinum based coatings, but it is in the right range for mild platinum or chrome. Performance of this 100 micron blade is very similar to the 90 micron RK New Chromium and the 95 micron Vidyut Super-Max Platinum. Having done absolutely no additional sleuthing for this one, I am guessing it is a Tigaksha blade of the same grind and coating as the RK New Chromium.

| Date | 22-Nov-2024 | Blade Thickness, mm | 0.100 | ||

| Blade | Super-Max UK | Dollar | Platinum | India | 1-Jan-2022 |

| Wear on Edge | 0 | 3 | 6 | 9 | 12 |

| Edges Measured | Bottom / Top | Bottom / Top | Bottom / Top | Bottom / Top | Bottom / Top |

| Measurement Medium | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 |

| Dulling Substrate | New | Paper | Paper | Paper | Paper |

| Measurements | 20 | 20 | 20 | 20 | 20 |

| Adj. Std. Dev. | 8 | 18 | 25 | 23 | 23 |

| Median F (g) | 67 | 64 | 65.5 | 67.5 | 73.5 |

| Mean F (g) Top | 65 | 62 | 65 | 63 | 71 |

| Mean F (g) Bottom | 71 | 73 | 84 | 86 | 92 |

| Mean F (g) | 68 | 67 | 74 | 74 | 81 |

| BESS Adj. Factor | 1.22 | 1.22 | 1.22 | 1.22 | 1.22 |

| Avg. Adj. F (g) Top | 79 | 76 | 79 | 77 | 86 |

| Avg. Adj. F (g) Bottom | 87 | 89 | 102 | 105 | 112 |

| Median Adj. F (g) | 82 | 77 | 80 | 82 | 90 |

| Mean Adj. F (g) | 83 | 82 | 91 | 91 | 99 |

Blade Sharpness Test Index

- Thread starter

- #1,059

This is the Starmaxx Superior Stainless HQ SMS 200 blade, which is made in India for the 2023 London company. Starmaxx UK Limited has a UAE website. I am not sure if Starmaxx is a reincarnation of some part of the R.K. Malhotra Supermax business, but the timing is right.

The tuck of five blades doesn't have an open flap. My tuck, as a bonus, came with one damaged blade and three good blades, rather than the usual five good blades. The tuck was in pristine condition, so the damage must have occurred before they went into the tuck.

There wasn't any evidence of damage to the individual I tested. It is a mid-thin 95 micron blade, mild-moderate in sharpness, with excellent durability and consistency. Despite the "Superior Stainless" branding, performance indicates a platinum based metallic coating.

The three stage grind is done with uneven abrasives, but the geometry prevents the scratches from weakening the apex.

After the test, we can see the failure mode of the steel is some small chipping, typical of good razor blade steel. The persistent polymer and metallic coatings are still visible.

There isn't another Indian 95 micron blade of similar performance and grind, though it is similar to the 100 micron V12. Use of 85 and 95 micron steels along with the normal 90 and 100 microns is an interesting choice by Indian blade producers.

It is fairly good for a moderate-mild blade ground with cheap abrasives, but it isn't worth the $11/100 street price. There are vastly superior blades at that price point. Also, positioning it as "Superior Stainless" when it clearly has a metallic coating is misleading and rubs me a bad way; I probably wouldn't even buy it if it were $5/100.

Blade Sharpness Test Index

The tuck of five blades doesn't have an open flap. My tuck, as a bonus, came with one damaged blade and three good blades, rather than the usual five good blades. The tuck was in pristine condition, so the damage must have occurred before they went into the tuck.

There wasn't any evidence of damage to the individual I tested. It is a mid-thin 95 micron blade, mild-moderate in sharpness, with excellent durability and consistency. Despite the "Superior Stainless" branding, performance indicates a platinum based metallic coating.

The three stage grind is done with uneven abrasives, but the geometry prevents the scratches from weakening the apex.

After the test, we can see the failure mode of the steel is some small chipping, typical of good razor blade steel. The persistent polymer and metallic coatings are still visible.

There isn't another Indian 95 micron blade of similar performance and grind, though it is similar to the 100 micron V12. Use of 85 and 95 micron steels along with the normal 90 and 100 microns is an interesting choice by Indian blade producers.

| Date | 23-Nov-2024 | Blade Thickness, mm | 0.095 | ||

| Blade | Starmaxx UK | Starmax | Superior Stainless | India | 1-Jan-2024 |

| Wear on Edge | 0 | 3 | 6 | 9 | 12 |

| Edges Measured | Bottom / Top | Bottom / Top | Bottom / Top | Bottom / Top | Bottom / Top |

| Measurement Medium | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 | Stren 6 .22 |

| Dulling Substrate | New | Paper | Paper | Paper | Paper |

| Measurements | 20 | 20 | 20 | 20 | 20 |

| Adj. Std. Dev. | 10 | 4 | 4 | 9 | 12 |

| Median F (g) | 66.5 | 60 | 60.5 | 62 | 65.5 |

| Mean F (g) Top | 60 | 59 | 59 | 60 | 64 |

| Mean F (g) Bottom | 74 | 61 | 62 | 70 | 72 |

| Mean F (g) | 67 | 60 | 60 | 65 | 68 |

| BESS Adj. Factor | 1.22 | 1.22 | 1.22 | 1.22 | 1.22 |

| Avg. Adj. F (g) Top | 73 | 72 | 72 | 73 | 78 |

| Avg. Adj. F (g) Bottom | 90 | 75 | 75 | 86 | 88 |

| Median Adj. F (g) | 81 | 73 | 74 | 76 | 80 |

| Mean Adj. F (g) | 82 | 74 | 74 | 79 | 83 |

It is fairly good for a moderate-mild blade ground with cheap abrasives, but it isn't worth the $11/100 street price. There are vastly superior blades at that price point. Also, positioning it as "Superior Stainless" when it clearly has a metallic coating is misleading and rubs me a bad way; I probably wouldn't even buy it if it were $5/100.

Blade Sharpness Test Index

Nice to see your sarcasm submodule is in fine fettle, todayMy tuck, as a bonus, came with one damaged blade and three good blades, rather than the usual five good blades.

And that's some "damage" there: it looks as if it were intended for a can of Pringles chips ("crisps") rather than a tuck of razor blades.

And they should have printed on the tuck: "Special - four blades for the price of five!"*

/Acey

*- For me, anytime the factory line cannot even get the packaging executed properly, it casts my doubts on everything upstream.

Last edited:

Similar threads

- Replies

- 2

- Views

- 457

- Replies

- 12

- Views

- 1K