So your Uncle gave you his old straight, or a friend picked one up for you because they know you shave like 'a crazyman', but you've only gotten as far as a DE (and the occasional lusting at straights in SOTD pics) you want to use it - only its a bit rough and you don't know quite what to do with it - what do you do? Sure, you can send it out to a pro, but that's expensive, and you're feeling pretty handy..........

After seeing more and more of these kinds of questions, I thought I'd create a thread showing that anyone with only the basic tools can bring a razor back to life well. Sure it wont be as good as one that a superpro has fixed, but there is a certain satisfaction that goes along with fixing it up yourself. I should also caveat that I'm no expert - but this is what works for me. I'll be working on a blade I saw on ebay, and even though it was a bit rough I couldnt help myself but get it anyway.

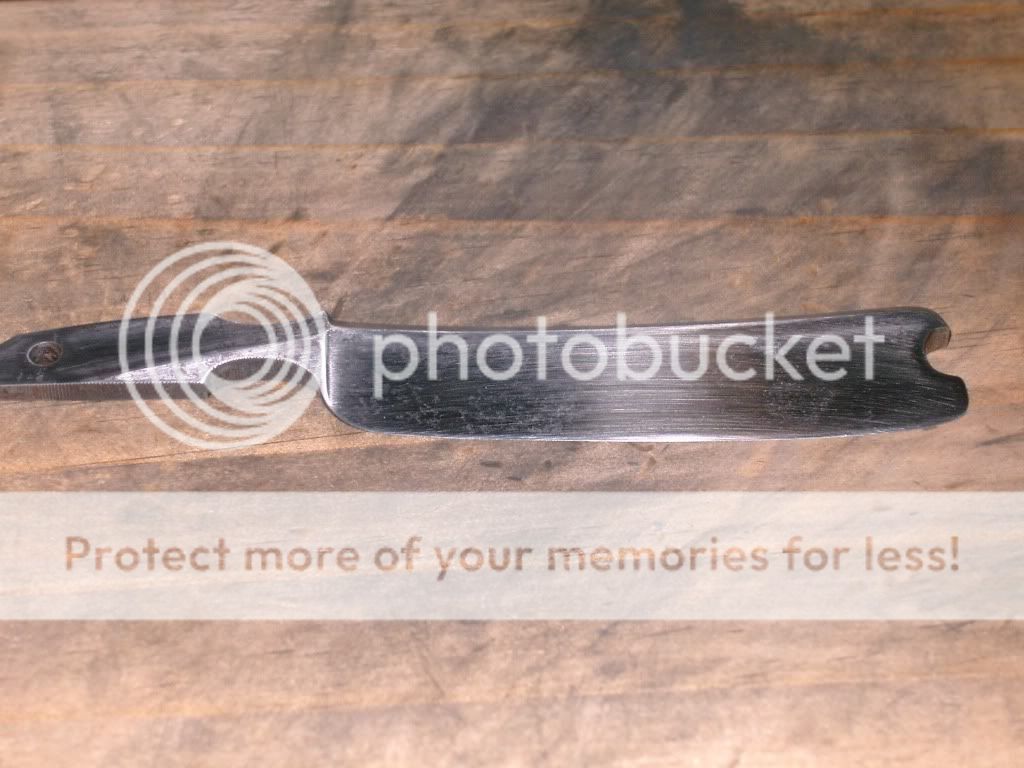

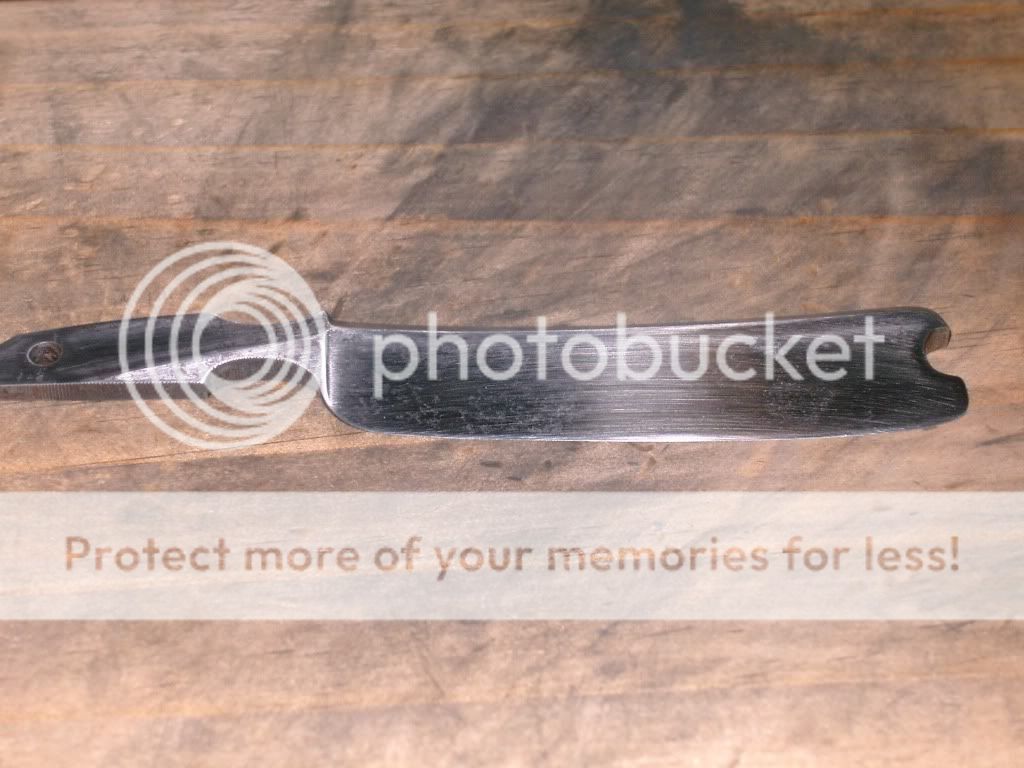

So here it is, just slid out of the envelope. The scales are clearly shot, and need to go. I used a hand drill with a tiny drill bit to drill out the pin on both sides, then I pushed a nail through and out it popped.

Lets get a better look at the condition of the blade...

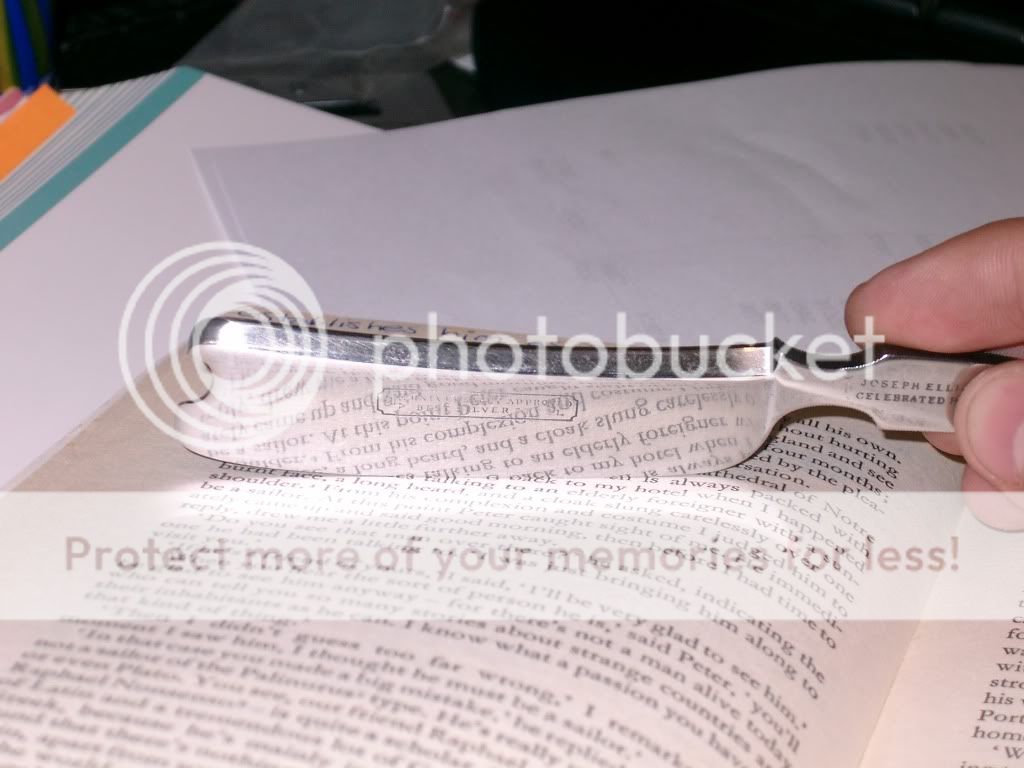

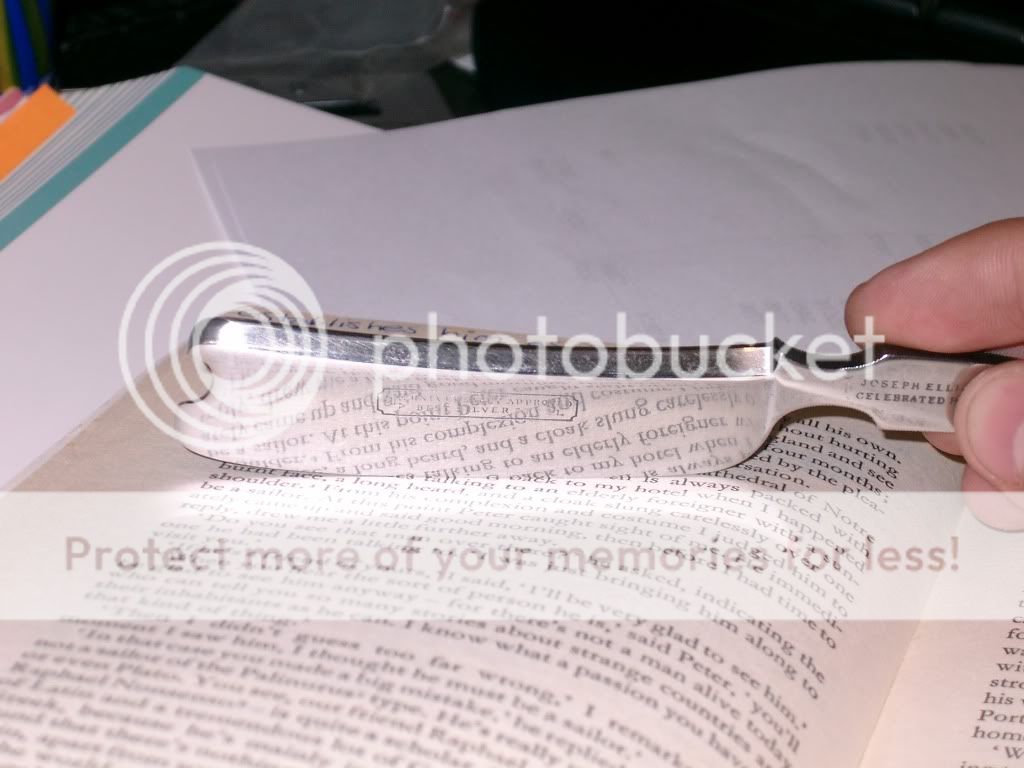

Bummer. Worse than I thought. This is even after I'd given it a little polish with a rag and Brasso to see what was loose junk and what was actually rust/stain on the blade.

However, most importantly, the edge is fine. If there was rust right on the edge it would probably not be worth saving it, and even if it was - its outside the skill range of the average guy.

You can see the brown patches of rust - there's sure to be pitting under there. There's also these strange scratches (check out the second pic in paticular) that will need dealing with.

So now what... now we need to remove metal. That gets rid of the junk just on the surface, but also by removing metal across the entire blade it makes the pits shallower. This is a wedge so its no problem to remove metal, but you have to be more careful on a more hollow (thinner) grind.

The weapon of choice for the shaver without a dremel is wet&dry sandpaper! I start at 240 grit, you can go lower but I dont like to make such deep scratches.

This is after a decent bit of sanding with 240. I sand in a circular motion, and then just when I'm about to move up a grit, do some sanding along the length of the blade. You can see that the rust and discolouration has been removed, but the pitting remains. The horisontal scratches are from the sandpaper.

Its frustrating as hell to stay at this grit when all you want to do is start moving up - but you really want to remove all the pitting you plan on removing at this level.

Once you've removed all you want to or can (because it's a thin blade, or like this one you dont want to remove interesting stamps on the blade) then you start moving up. Then its 360, 400, 600, 800, 1200 and 2000 if you can find it (often at auto shops). Remember to remove all the scratches of the previos grit before you move to the next one. I spray a little WD40 on the blade every so often while im sanding, and it seems to make it go a little easier.

You can stop here if you like, the blade has all the rust removed, and will look pretty good, and have a fairly decent satin finish. If you want to go down the mirror polish road though, you need some more tools.

No, not a dremel... micromesh! I picked up a lot of cloth backed micromesh in grits 1500, 1800, 2400, 3200, 3600, 4000, 6000, 8000, 12000 on ebay for like $30. Use it just like sandpaper.

And after some attention from the micromesh.....

Looking good, though still not perfect. Some more rag and brasso action is needed!

Until...

Shazam! Mirror polish with only hand tools!

There's still a bit of pitting in the blade that I could have removed, but I like the looks of it being a little worn and used, I think it goes with this blades crazy curves and points.

So thats it, easy as pie. It will take a couple hours for all that sanding, but it's worth it in the end. Not a professional finish, but one you've done yourself and can be proud of

And finally, at work, in one of my favourite SOTD pics

After seeing more and more of these kinds of questions, I thought I'd create a thread showing that anyone with only the basic tools can bring a razor back to life well. Sure it wont be as good as one that a superpro has fixed, but there is a certain satisfaction that goes along with fixing it up yourself. I should also caveat that I'm no expert - but this is what works for me. I'll be working on a blade I saw on ebay, and even though it was a bit rough I couldnt help myself but get it anyway.

So here it is, just slid out of the envelope. The scales are clearly shot, and need to go. I used a hand drill with a tiny drill bit to drill out the pin on both sides, then I pushed a nail through and out it popped.

Lets get a better look at the condition of the blade...

Bummer. Worse than I thought. This is even after I'd given it a little polish with a rag and Brasso to see what was loose junk and what was actually rust/stain on the blade.

However, most importantly, the edge is fine. If there was rust right on the edge it would probably not be worth saving it, and even if it was - its outside the skill range of the average guy.

You can see the brown patches of rust - there's sure to be pitting under there. There's also these strange scratches (check out the second pic in paticular) that will need dealing with.

So now what... now we need to remove metal. That gets rid of the junk just on the surface, but also by removing metal across the entire blade it makes the pits shallower. This is a wedge so its no problem to remove metal, but you have to be more careful on a more hollow (thinner) grind.

The weapon of choice for the shaver without a dremel is wet&dry sandpaper! I start at 240 grit, you can go lower but I dont like to make such deep scratches.

This is after a decent bit of sanding with 240. I sand in a circular motion, and then just when I'm about to move up a grit, do some sanding along the length of the blade. You can see that the rust and discolouration has been removed, but the pitting remains. The horisontal scratches are from the sandpaper.

Its frustrating as hell to stay at this grit when all you want to do is start moving up - but you really want to remove all the pitting you plan on removing at this level.

Once you've removed all you want to or can (because it's a thin blade, or like this one you dont want to remove interesting stamps on the blade) then you start moving up. Then its 360, 400, 600, 800, 1200 and 2000 if you can find it (often at auto shops). Remember to remove all the scratches of the previos grit before you move to the next one. I spray a little WD40 on the blade every so often while im sanding, and it seems to make it go a little easier.

You can stop here if you like, the blade has all the rust removed, and will look pretty good, and have a fairly decent satin finish. If you want to go down the mirror polish road though, you need some more tools.

No, not a dremel... micromesh! I picked up a lot of cloth backed micromesh in grits 1500, 1800, 2400, 3200, 3600, 4000, 6000, 8000, 12000 on ebay for like $30. Use it just like sandpaper.

And after some attention from the micromesh.....

Looking good, though still not perfect. Some more rag and brasso action is needed!

Until...

Shazam! Mirror polish with only hand tools!

There's still a bit of pitting in the blade that I could have removed, but I like the looks of it being a little worn and used, I think it goes with this blades crazy curves and points.

So thats it, easy as pie. It will take a couple hours for all that sanding, but it's worth it in the end. Not a professional finish, but one you've done yourself and can be proud of

And finally, at work, in one of my favourite SOTD pics

Thanks to my chat buddy SlagleRock for a proof read!

[/QUOTE]

Last edited: