A smiling razor is a big advantage to me and worth preserving. I believe they take a very consistent rolling x stroke to hone.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

honing off a chip

- Thread starter papi

- Start date

- Thread starter

- #22

thank you for the guide and tips, much appreciated.

- Thread starter

- #23

Just cut off the rust with a single edge razor blade and polish with 000 steel wool and WD40.

It does not matter how you remove the steel, the exact same amount of steel will need to be removed to the bottom of the chip and you will still need to cut a new bevel, not a big thing. When you do that, the heel will come around. It will need reprofiling anyway.

But this is an opportunity to make something unique and cool while making the repair, The steel must come off anyway.

Sounds like you plan to take your time and look at your options.

Trace your razor onto a piece of card stock, carefully cut out the razor profile. Now use the spine cut out, the positive or negative, does not matter to draw a matching spine profile on the posterboard edge, so that you remove a minimum of steel at the heel, the narrowest part of the razor.

You do not need to make the smile/curve exactly the same as the spine, so that the toe and heel match in width, but with the cardboard templates traced onto poster board you can experiment with different edge treatments before any steel is removed.

Once you have settled on one or two potential shapes, cut out the new shape and trace that profile onto the razor edge with a black sharpie. That will give you a very good preview of what the razor will look like when finished. You can mark either side differently and decide which profile you prefer. WD40 and a paper towel will remove all the sharpie.

Invest in a pair of plastic calipers, $10-15 and take lots of measurements before any steel is removed. Once you decide, remove the steel, I use a 140-diamond plate or a 600/1000 diamond file. The metal is thin and goes quickly, and like I said it does not matter how you do it, as long as you have lots of control.

As I said earlier, “Also, be aware that impact, chip damage often goes much deeper than the bottom of the chip, so do not be surprised if after the chip is removed, that the razor microchips after a few days shaving and stropping.”

Nice project, enjoy and learn something new.

View attachment 1735091

I have learned from everyone on this forum and it is my motto in life to do so.

With this razor stuff, I am sure you understand how we learn as we go with skills and experiences.

As you have noted it does not matter how you remove the metal you just do it carefully.

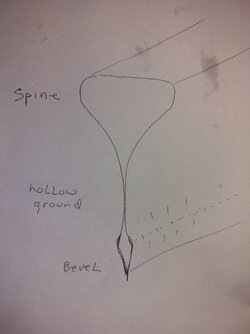

You know when you look at the profile of this blade from the front looking at the taper and hollow ground.

This Wade and Butcher has a very fine hollow ground maybe it is a double hollow ground, not sure. You know how it is a bit thicker at the edge and then bevels to an apex. Above the edge it really is hollow, much more hollow than at the bevel.

I was forced to keep the repaired edge straight because the hollow ground follows the edge so nicely. The rust came off easily and did not leave any pits of any kind. Removing the metal was not difficult because this razor has a very thin profile.

As you said, above the chip can be compromised. It is compromised with a small blemish. It seems solid for, it's microscopic only in a color difference, like a blemish that you can not see without magnification. I can see the area where the chip once was by this tiny blemish. I do not want to take more metal off because the hollow ground is so nice and I really think it is not a problem.

I have not honed this razor yet above a 400-grit diamond stone. I just cleaned it up for now. It is a fine razor, that was very well made. I was able to micro-sand the horn handle and it's in clean condition. I know for a fact that all Wade and Butchers are not equal. I have myself a deal on this one.

I really enjoyed this and I know it is going to be a fine shaver. It will not take much to get a good shave-ready edge on this razor. I have been working with primitive hunks of metal and this one is like a good-running BMW in comparison to an old Volk's wagon.

I hope you guys do not mind me going on and on about things. It is so interesting for me.

I will advance to a smile razor eventually after I find a good razor to learn with. What I just learned, I am wondering if a smile razor has a different type of hollow ground. My instincts tell me that it is only tapered and not with a hollow ground. I do not know. If a smile is tappered then the taper changes as the edge curves up. I will get a smile edge razor that needs work and take specs eventually. I am curious though.

Thanks to all,

Attachments

Last edited:

- Thread starter

- #24

here is a drawing of what I was trying to write in the above reply.

The hollow ground becomes thicker at the bevel area. That follows straight at the edge and bevel.

I can understand how a machine grinder can perform that task.

When it comes down to a blade having a smile from the factory, I wonder who they hollow grind that and or how someone restoring a razor with a smile deals with that. I am not asking for an answer now, but I eventually will find this out.

the above razor is so very delicately made. It is rather amazing, to say the least.

Here is another point. A razor like this one will not last as long as others because once it is honed past that bulge at the bevel. It has lost its integrity. the bevel angle will be destroyed.

The hollow ground becomes thicker at the bevel area. That follows straight at the edge and bevel.

I can understand how a machine grinder can perform that task.

When it comes down to a blade having a smile from the factory, I wonder who they hollow grind that and or how someone restoring a razor with a smile deals with that. I am not asking for an answer now, but I eventually will find this out.

the above razor is so very delicately made. It is rather amazing, to say the least.

Here is another point. A razor like this one will not last as long as others because once it is honed past that bulge at the bevel. It has lost its integrity. the bevel angle will be destroyed.

Attachments

It's a compromise, which cannot be helped, your razor was a bellied hollow, and the chip so happened to be on the bellied part of the razor, so you could either bin the project or as you have rightly done remove it and create a new bevel. your razor is now a razor with a full hollow grind instead of a bellied hollow grind.

- Thread starter

- #26

That is something. There is actually a name for it, "bellied hollow" There is actually still a good portion of the belly left. I guess I over-exaggerated both in my drawing and also in my poorly written explanation.It's a compromise, which cannot be helped, your razor was a bellied hollow, and the chip so happened to be on the bellied part of the razor, so you could either bin the project or as you have rightly done remove it and create a new bevel. your razor is now a razor with a full hollow grind instead of a bellied hollow grind.

Thanks.

It's a used razor with a chip in the edge. Which is just about one of the most common things in the world of vintage straight razors. It's not a museum piece.

Sand the rust off. Get the blade on a stone and hone it.

You won't kill it and even if you do kill it there are pleny of those fish in the sea.

Hone till you clear the chip and a bit more, inspect. Set the bevel. Shave with the bevel set. If that flies you're good to go.

Seriously, open a window and let the hot air in here escape.

It's a razor. Hone it. Strop it. Shave with it. Done. Repeat.

Sand the rust off. Get the blade on a stone and hone it.

You won't kill it and even if you do kill it there are pleny of those fish in the sea.

Hone till you clear the chip and a bit more, inspect. Set the bevel. Shave with the bevel set. If that flies you're good to go.

Seriously, open a window and let the hot air in here escape.

It's a razor. Hone it. Strop it. Shave with it. Done. Repeat.

- Thread starter

- #28

Hay buddy, I just buried my brother 36 hours ago and this took my mind off things. I won't be bothering with this anymore. I don't want to walk on pins and needles worrying about ruffling your feathers over something as insignificant as a Razor. Maybe you would like to talk about the science of grit a little more to show that you have the ability to read and pick up some information, to show off your shiny razors. 99 percent of the time people do not mind what you refer to the hot air.It's a used razor with a chip in the edge. Which is just about one of the most common things in the world of vintage straight razors. It's not a museum piece.

Sand the rust off. Get the blade on a stone and hone it.

You won't kill it and even if you do kill it there are pleny of those fish in the sea.

Hone till you clear the chip and a bit more, inspect. Set the bevel. Shave with the bevel set. If that flies you're good to go.

Seriously, open a window and let the hot air in here escape.

It's a razor. Hone it. Strop it. Shave with it. Done. Repeat.

I have a feeling that I was sharpening tools when you were a little boy or if not you were not even born. If you are older start acting your age.

so buzz off Gamma. I suppose the narrator will remove this reply so you can keep your puffed-up composure.

My condolences, sorry for your loss.

We're not buddies.

We are just two members of an internet discussion forum.

I buzz when I feel like it..and I don't feel like it.

You started this thread off by asking for suggestions about honing this blade....

If you want to hone it, then hone it.

It's a simple process. Steel, stone, hone, done.

My suggestion is to not make a big deal out of it and just hone it.

We're not buddies.

We are just two members of an internet discussion forum.

I buzz when I feel like it..and I don't feel like it.

You started this thread off by asking for suggestions about honing this blade....

If you want to hone it, then hone it.

It's a simple process. Steel, stone, hone, done.

My suggestion is to not make a big deal out of it and just hone it.

I’m so sorry for your loss. Please accept my sincere condolences!I just buried my brother 36 hours ago

- Thread starter

- #32

thank you I appreciate thatI’m so sorry for your loss. Please accept my sincere condolences!

- Thread starter

- #33

I should of addressed you as chump rather than buddy. I said buzz off because I am a gentleman and I would not want to be vulgar, even with serious matters in life.My condolences, sorry for your loss.

We're not buddies.

We are just two members of an internet discussion forum.

I buzz when I feel like it..and I don't feel like it.

You started this thread off by asking for suggestions about honing this blade....

If you want to hone it, then hone it.

It's a simple process. Steel, stone, hone, done.

My suggestion is to not make a big deal out of it and just hone it.

You like to criticize and it is unnecessary. Your were derogative and you don't even know it. Who needs that?

Like I said, I was sharpening tools in my trade before you were born. I am sure of it now by the way you replied.

If you suggest don't make a big deal out of it. What makes showing off your razors and your work and your stones and your knowledge of how synthetic stones are made so special for you?

Maybe someday you will buzz off when you feel like it.

God Bless all you guys. I really respect some of the kind ways people have gone out of their way to make this very interesting and actually fun.

Now I have lots of honing to do, with many hundreds of dollars of stones and a drawer full of used old rusty razors. I have learned everything I need to know, maybe too much from this last post.

I am too old for the conflicts where I have to be cautious about asking a couple legitimate questions, when there is a razor cop stalking the forum; ready to hand out tickets for violations with insults.

Not interested in taking any of the bait, but thanks for the laughs.

A used razor with a chip in the edge is a common occurrence.

In and of itself, it's not a big deal.

Honing a chipped razor is the same as honing any razor.

It's just that the chipped blade needs to be honed more.

That's it.

A used razor with a chip in the edge is a common occurrence.

In and of itself, it's not a big deal.

Honing a chipped razor is the same as honing any razor.

It's just that the chipped blade needs to be honed more.

That's it.

- Thread starter

- #35

Not interested in taking any of the bait, but thanks for the laughs.

A used razor with a chip in the edge is a common occurrence.

In and of itself, it's not a big deal.

Honing a chipped razor is the same as honing any razor.

It's just that the chipped blade needs to be honed more.

That's it.

what worked best for me with that razor was filing down the edge first with the blade perpendicular to the stone. I already received very sound good suggestions from people. Your about 2 days late.

by the way Thanks for the condolences.

Last edited:

- Thread starter

- #36

OK, lets move on now.

- Thread starter

- #38

thank you.OK, lets move on now.

Exactly - what matters is the results.

Pix of the finished blade would be ideal.

Pix of the finished blade would be ideal.

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 21

- Views

- 2K