Apollo-Mikron Education

- This is a thread to show people why zinc alloys (pot metal) in general are a bad choice for razors and especially if the razor has an "advanced" construction.

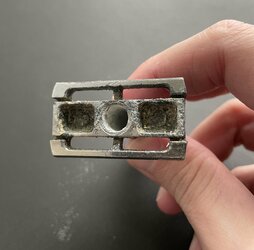

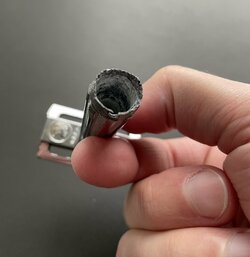

- I was recently given another Apollo-Mikron 2.gen razor for free because it wasn't functioning(first pictures). The corrosion of the metal was obvious though and I didn't expect much.

- Nevertheless I tried to use some lime scale remover and it cleaned the razor somewhat on the outside. That being said this razor was a total lost cause and it was corroded a lot which made it more or less impossible for me to take it apart in a gentle way.

- I therefore decided to take it apart using some different tools and some more force. I succeeded and I'm glad I did because I wanted to see how the 2.gen Apollo-Mikron looks inside compared to the 3.gen.

- The 2.gen is clearly not meant to be taken apart because some of the construction is press fitted together unlike the 3.gen where it's screwed together with threads.

- It's clearly to see where the manufacturer made some improvements and constructed the razor in a more optimal way with the 3.gen model. No wonder the 2.gen and I assume 1.gen will totally clog up with time and not work properly if not used wisely.

- The pictures shows the different parts after they have already been partly cleaned, so you can imagine what kind of disaster I was met with when I first got it opened

- Hopefully this thread will provide a little material to those interested in a bit of product development.

- These German tanks will always be awesome, but the overall condition is paramount, so be careful when looking for one for your collection.