“Does anyone knows is the scales can be celluloid with that color?”

Yup, celluloid, that color and swirl combination were popular but the swirl pattern can also off glass, keep an eye on them.

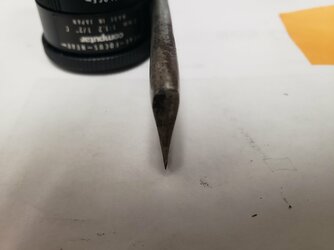

Nice clean up and heel reprofile. Love the badge/inlay.

Yup, celluloid, that color and swirl combination were popular but the swirl pattern can also off glass, keep an eye on them.

Nice clean up and heel reprofile. Love the badge/inlay.