Are the new blades the ones in the package on the left?I really enjoy these blade test because he answers a lot of questions that nag at me. Like a splinter in the back of my mind, to quote Morpheus.

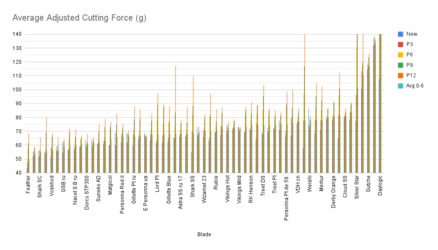

The test between pre and post June, 2020 Wizamets was a good example.

Your previous post brings up another:

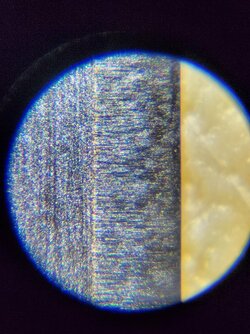

View attachment 1885278

The blades on the right. I've seen multiple claims that they're made in Israel but no proof. Yes, they probably are but there is nothing, zilch, nada on the box or tuck to indicate where they were made, just

Superior Technology from American Safety Razor Co., USA.

My Israeli Reds say Blades made in Israel right on the tuck and hanger. Yes, they may very well be the same blade/steel/grind but a test could answer that definitively.

So for me, that is one of the great side benefits of the tests and tedious work Dan is doing here and I hope I'm speaking for all of us by saying...

Thank You!

Personally I would judge the package on the left to be older than the other packages on the right.