- Thread starter

- #21

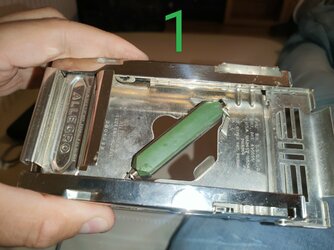

I found mine in an antique store for about $25, i started this thread because searching in 2013 didn't get much info about them. I thought it looked really cool and thought you should see it.

Our patents are the same except USA 1862452, i should probably verify that one.

So i guess it appears that:

- They may have started off as painted, then went shiny. Maybe had a cheap/expensive model.

- Then added tension setting later in the run.

- Shaving stuff is cool.

Post 17, picture 9 kinda shows how much the blade flexes over the stone on med. tension.

I saw one other of these back around 1998 while clearing out my grandmas house, in a big box of SE, DE, straight razor stuff that my aunt ended up taking. It was also shiny, had a spare triangle stone. I don't remember if it had a box or directions.

Our patents are the same except USA 1862452, i should probably verify that one.

So i guess it appears that:

- They may have started off as painted, then went shiny. Maybe had a cheap/expensive model.

- Then added tension setting later in the run.

- Shaving stuff is cool.

Post 17, picture 9 kinda shows how much the blade flexes over the stone on med. tension.

I saw one other of these back around 1998 while clearing out my grandmas house, in a big box of SE, DE, straight razor stuff that my aunt ended up taking. It was also shiny, had a spare triangle stone. I don't remember if it had a box or directions.