- Thread starter

- #61

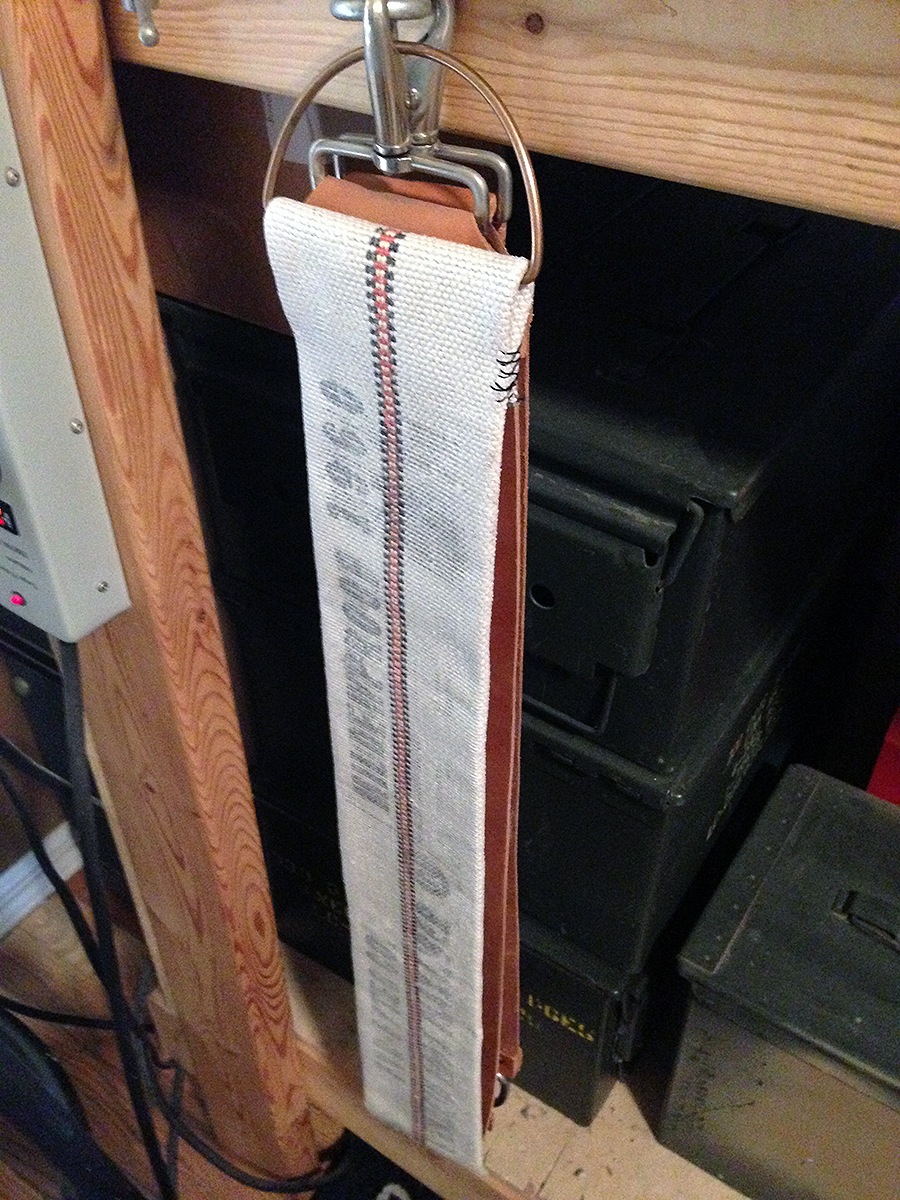

The bench top shortie is awesome!!

Thank you - I'm loving that piece. That was actually just a stitch-test that wound up working out well, I might make another one, maybe an inch longer. That one in the photo is great for the cabinet in the bathroom, I'd like a slightly longer one on the bench.

The amount of DIY and repurposed fire hose stuff out there is amazing - Wallets, handbags, purses, etc. I had no idea anyone was doing anything with this stuff until I started researching it.

Have no knowledge or association with seller but found these for those interested:

http://www.ebay.com/itm/221608283364?_trksid=p2060778.m1438.l2649&ssPageName=STRK%3AMEBIDX%3AIT

Has anyone confirmed if he's using all flax fiber hose or a blend? Doesn't matter in a better/worse way, just wondering.

If I don't get any negative feedback from anyone, I have a few pieces sitting on my desk to go out, just for fun. I know I used the word 'testing' and all but I really should have handled that differently - I just want to make sure I'm not sending people down a dead end and that there's no problems. The hose is, well - ugly, dirty, old, used, etc - and I was thinking that it could possibly be problematic or a waste of time. My experience so far is very good - but a few positive feedbacks from others would bolster my confidence.If you're asking for volunteers, I'd be happy to pay shipping (and beer money) on a piece....

Oh, and yeah - your name is on the top of the list.