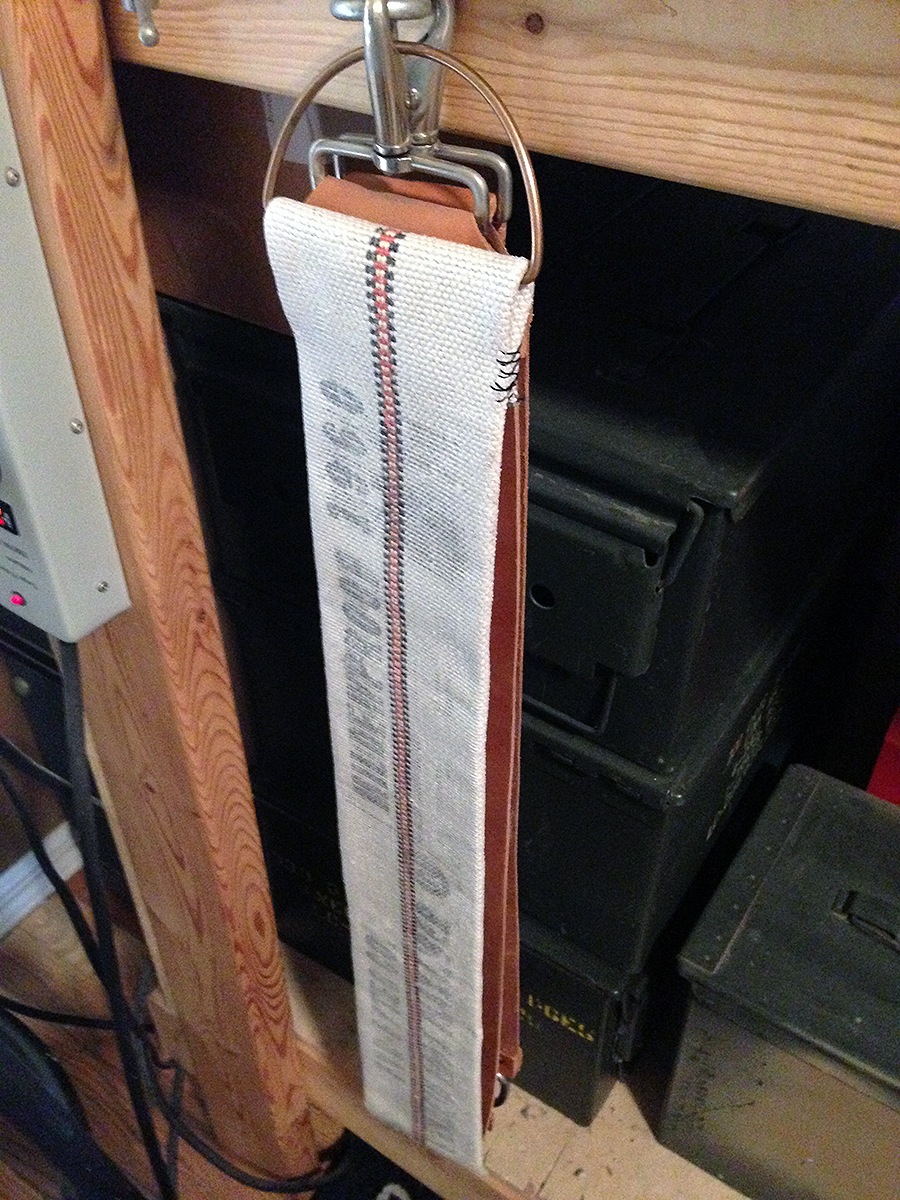

I came upon a length of old unlined fire hose in Iraq. I used hot soapy water, a stiff brush and elbow grease to clean it. When wet it gets stiff as a board. Once dry and worked a bit it softens right up. I used it for a couple years with really good results until I became interested in professionally made strops.

Chasmo

Chasmo