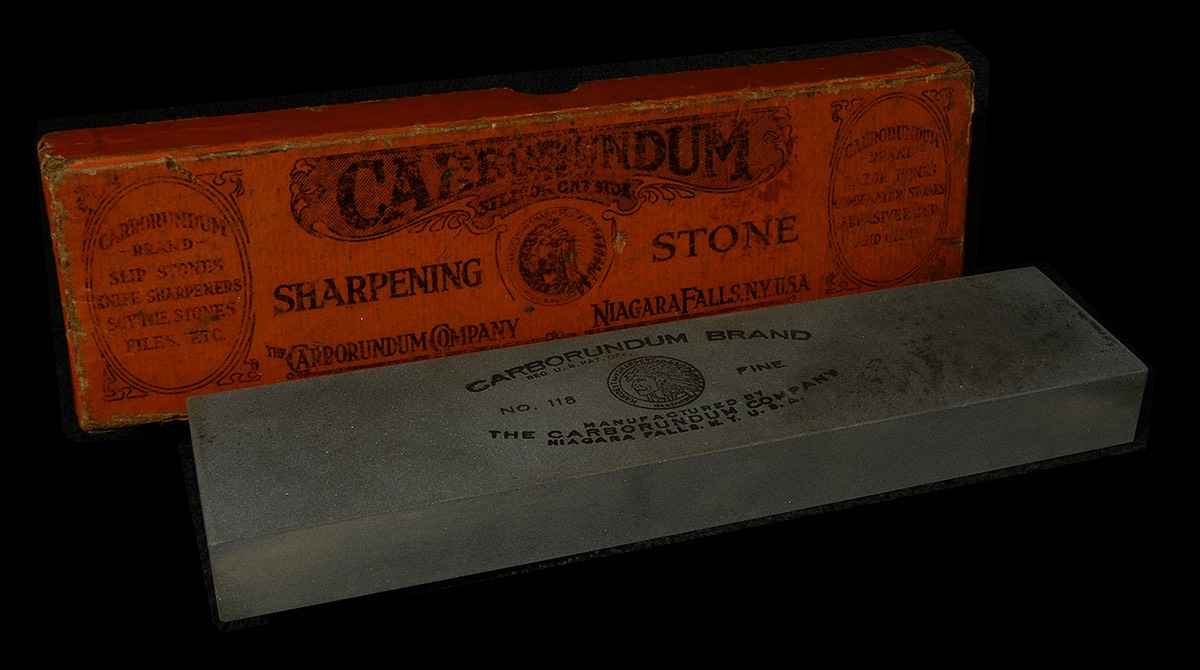

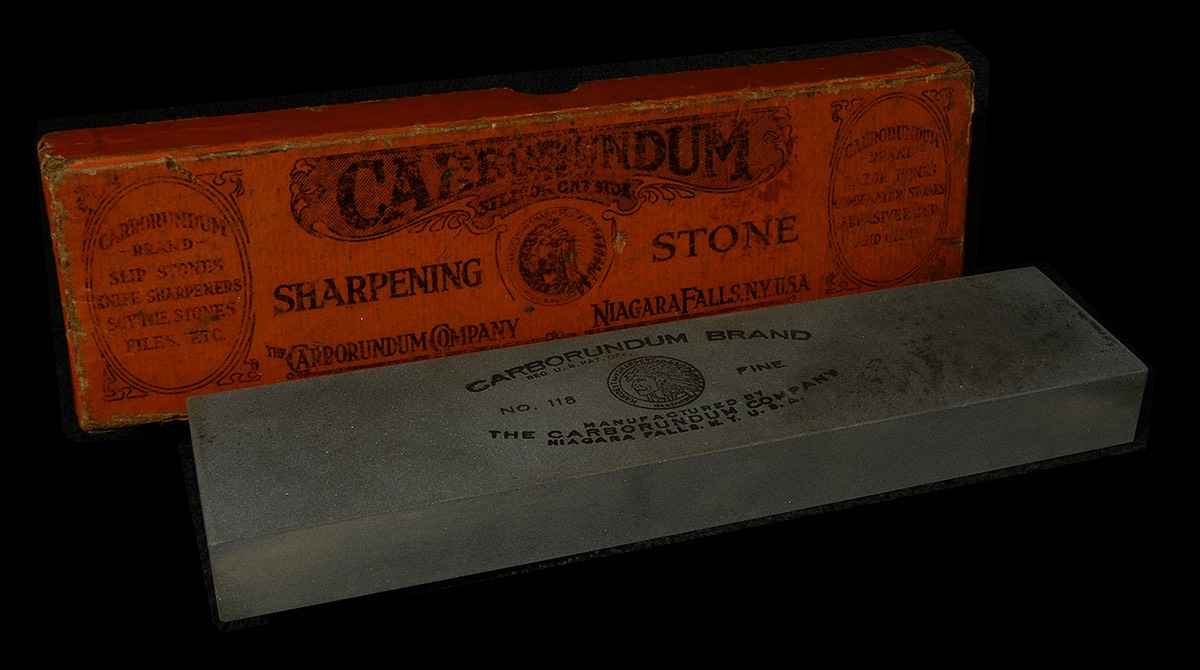

Carborundum #118.

Note - this is not a larger version of the #118s baber hone; this one is harder, coarser, and not a 'razor hone'.

But - this is a good option for a 1k-ish stone to set razor bevels with - could be wider but the price was good and the box is pretty cool.

It's 8x2x.75". These may have been made in other sizes but I'm not sure.

It's fast - real fast. It set a bevel on an auction site blade so fast it made me laugh.

Like all of these stones - how the surface is lapped and what lubricant is used will have a lot to say about how fast and 'fine' it is.

Basically - it's an oil stone but it can be used with water/soap - probably glycerine/water also.

I think that oil smudge on the right side will come out with a bit of oven cleaner. If not, it's no problem.

The honing surface cleaned up perfectly with lapping - looks brand new.

Works well for kitchen cutlery also - put a nice edge on a chef's knife really quickly.

Note - this is not a larger version of the #118s baber hone; this one is harder, coarser, and not a 'razor hone'.

But - this is a good option for a 1k-ish stone to set razor bevels with - could be wider but the price was good and the box is pretty cool.

It's 8x2x.75". These may have been made in other sizes but I'm not sure.

It's fast - real fast. It set a bevel on an auction site blade so fast it made me laugh.

Like all of these stones - how the surface is lapped and what lubricant is used will have a lot to say about how fast and 'fine' it is.

Basically - it's an oil stone but it can be used with water/soap - probably glycerine/water also.

I think that oil smudge on the right side will come out with a bit of oven cleaner. If not, it's no problem.

The honing surface cleaned up perfectly with lapping - looks brand new.

Works well for kitchen cutlery also - put a nice edge on a chef's knife really quickly.

Last edited: