Very nice it's really taking shape now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My own SE razor - made by hand

- Thread starter wquiles

- Start date

William

thanks for sharing. It is a great concept. I too would be curious about one that uses a DE blade cut in half. Your appreciation for the Feather KAI blades is understood, but with a DE the sky is the limit on blades. I have a Shavette that I chose to accept half DE blades just because I didn't want to be locked into a few blades.

Had you considered imbedding the magnets in the base and having the magnets in top affixed to a hinged door that could be lifted for blade change? that way it would be a one piece razor with no individual magnets to place. With these modern magnets, it could really clamp the blade in tight. I am definitely subscribed, so keep us posted.

thanks for sharing. It is a great concept. I too would be curious about one that uses a DE blade cut in half. Your appreciation for the Feather KAI blades is understood, but with a DE the sky is the limit on blades. I have a Shavette that I chose to accept half DE blades just because I didn't want to be locked into a few blades.

Had you considered imbedding the magnets in the base and having the magnets in top affixed to a hinged door that could be lifted for blade change? that way it would be a one piece razor with no individual magnets to place. With these modern magnets, it could really clamp the blade in tight. I am definitely subscribed, so keep us posted.

William

I was wondering if your idea is sufficiently different than other razors. Enough so that it could/should be patented? I think the concept has real merit. watch out for s

s

I was wondering if your idea is sufficiently different than other razors. Enough so that it could/should be patented? I think the concept has real merit. watch out for

s

sSubscribed!

- Thread starter

- #25

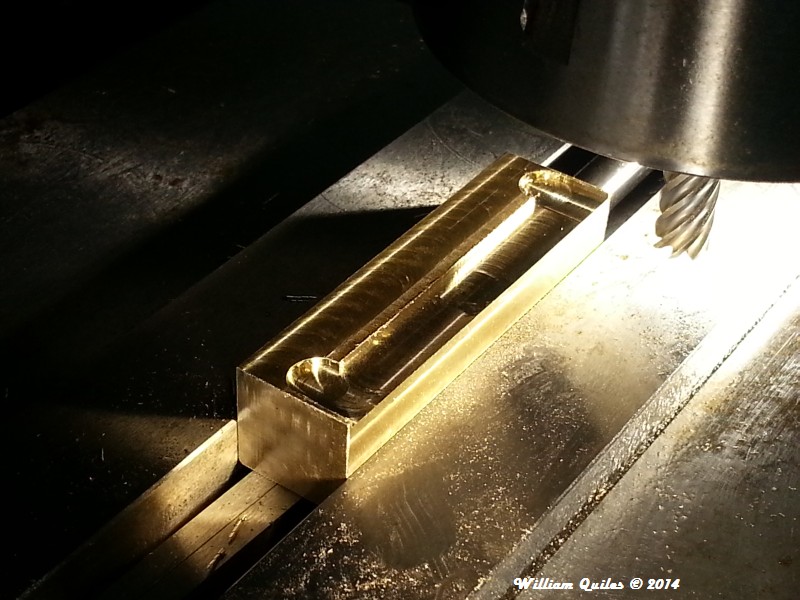

I machined the cut-out on the top of the razor to be just about 0.002" wider than the blade, and deep enough to allow a Feather Light, Feather Guard, Feather Pro, and Feather Super to stick out past the edge. So except for the cutting edge, the whole blade surface is supported while shaving. So I literally built the razor around this one type of Feather/KAI blade:William

thanks for sharing. It is a great concept. I too would be curious about one that uses a DE blade cut in half. Your appreciation for the Feather KAI blades is understood, but with a DE the sky is the limit on blades. I have a Shavette that I chose to accept half DE blades just because I didn't want to be locked into a few blades.

I can easily do the same with any other blade size, but obviously the razor head's dimensions would change to fit the other blade. Doing the same with a 1/2 DE blade will result in a narrower razor head, but a little deeper since 1/2 a DE blade is wider than the Feather/KAI blades. The fact that the Feather/KAI blades are narrower makes for a smaller profile razor, which is useful when shaving (for example) the mustache area under the nose:

So yes, making a new, wider razor head for 1/2 DE's blades is totally doable. Now, my design takes into advantage that the back of the Feather/KAI blades (edge opposite to the cutting edge) is perfectly flat, and since the cut/break line on a 1/2 DE blade is not always precise, the blade could/would not fit perfectly as these Feather/KAI blades fit - probably not an issue, but a small little detail to think about.

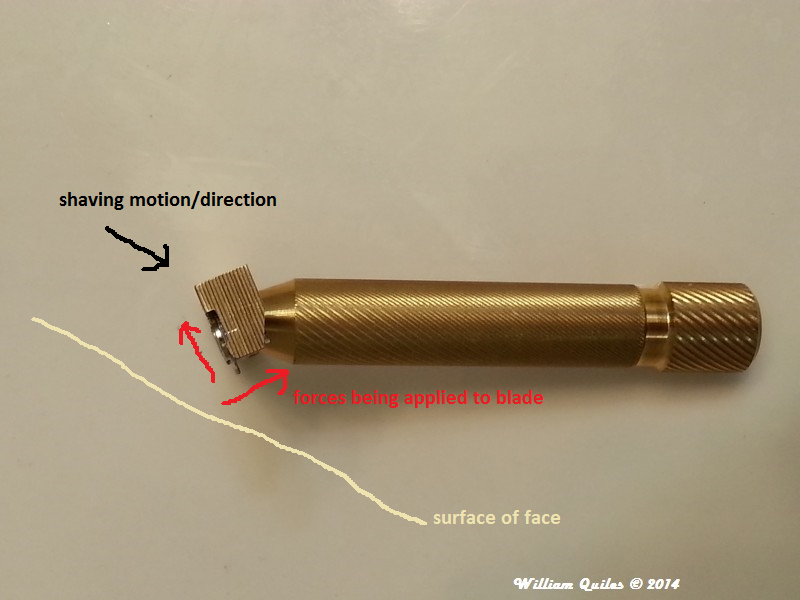

Yes, that was my "Plan B" if the magnets did not work. Note that since the blade is fully supported on the back (edge opposite to the cutting edge), and both sides, even with extremely small magnets, as long as you are shaving at 45 deg or less to the face, the forces against the blade keep the blade in place. Here is a quick and crude hand drawing showing what I mean:Had you considered imbedding the magnets in the base and having the magnets in top affixed to a hinged door that could be lifted for blade change? that way it would be a one piece razor with no individual magnets to place. With these modern magnets, it could really clamp the blade in tight. I am definitely subscribed, so keep us posted.

So as long as you shave at 45 deg or less, shaving actually pushes against the support areas, so the blade can't move. Now, if you shave at an angle greater than 45 degrees, then one of the forces against the blade would actually try to pull the blade away from the face. Even though this would result in a very rough and uncomfortable shave, that is where the strong magnets come in place, by pulling hard into the razor head. So in reality, with a normal shave angle range (say 35-5 degrees, although I personally prefer small angles), you "almost" don't even need the magnets in the first place, other than to prevent the blade from falling out due to gravity in between strokes. Note that although you "could" use small/weak magnets, I would not recommend them. I now have 12x shaves with this new "system" and I still like the extra sense of confidence these 4x very strong magnets provide in keeping the blade in place

Yes, absolutely, and I though of that before posting pictures. I do have a patent through a past employer, so I have been through the whole process already. But what does a patent "really" does? It provides a legal standing so that you can go into court and sue a person/entity for using your idea for profit. That means that you have to still have ten's of thousands of dollars out of your own pocket to defend your idea, and try prevent others from making a profit from your idea. If you are a large corporation like Samsung, Apple, Intel, etc. who has reams of lawyers in their personnel, it is very worthwhile to patent your ideas since you are talking about 100x, 1000x or more times, the money making potential, than your cost for the lawyers. For me, a home tinkerer, doing stuff as a hobby and for personal use, I would never afford the legal fees, so it is not worth spending $5-10K to get a patent in the first place.William

I was wondering if your idea is sufficiently different than other razors. Enough so that it could/should be patented? I think the concept has real merit. watch out fors

In fact, the reason I had these magnets already is that I used them for a magnetic ring selector for flashlights that I invented 2-3 years ago (think of a "dimmer light" switch, but instead of the light in a room, the dimmer controlled the output of a hand-held portable LED flashlight). Within 6 months flashlights from China started coming out with "my" idea. Even if I had a patent, what can/could I do? Or better, what could I "afford" to do? Nothing. In fact, I currently EDC one of those Asian-made flashlights using my idea - it works really well, and it was smaller than this prototype I made in my shop

Last edited:

William

regarding the half DE blade alignment. the Shavette razors that use them don't rely on the position of the cut to index the blade. They use the same holes that the pegs in the conventional razor index on. So the half blade is slid against the pegs or other stop embedded in the body to mate with the half holes. In this way the position of the cut is not that important so long as it is close-ish.

On the patent. I really am naive as to what kind of protection your patent could provide. I guess I was thinking that your idea does have merit and as such if you were the patent holder you'd have standing to sell it to a bigger concern. Alternately if a big concern did steal it and become invested in it so that their deep pockets were exposed, you'd be in a better position to negotiate with a law firm willing to take the case for a cut. These are just idle ramblings of the uninformed, so not worth much.

regarding the half DE blade alignment. the Shavette razors that use them don't rely on the position of the cut to index the blade. They use the same holes that the pegs in the conventional razor index on. So the half blade is slid against the pegs or other stop embedded in the body to mate with the half holes. In this way the position of the cut is not that important so long as it is close-ish.

On the patent. I really am naive as to what kind of protection your patent could provide. I guess I was thinking that your idea does have merit and as such if you were the patent holder you'd have standing to sell it to a bigger concern. Alternately if a big concern did steal it and become invested in it so that their deep pockets were exposed, you'd be in a better position to negotiate with a law firm willing to take the case for a cut. These are just idle ramblings of the uninformed, so not worth much.

- Thread starter

- #27

Yup, a total different blade holding system than mine. Here a picture of my own SS Parker Shavette:the Shavette razors that use them don't rely on the position of the cut to index the blade. They use the same holes that the pegs in the conventional razor index on. So the half blade is slid against the pegs or other stop embedded in the body to mate with the half holes. In this way the position of the cut is not that important so long as it is close-ish.

My system is more like the Feather razors, where the back "pocket" on the lower jaw (you can clearly see it in this picture) aligns the blade with the straight back portion if the blade. Of course, instead of a "top" plate as in my Feather DX below where force is applied "down" into the bottom jaw to hold the blade from moving, in my design, the 4x magnets pull down on the blade itself to keep the blade from moving (that is also why this razor is made our of brass - non magnetic):

I still have to spend $5-10K just to get the patent processed through all its stages, which is a process that takes several years (I got my patent awarded 4 years after it was accepted by the patent office, of course my employer at the time paid for everything, since they get to "keep" the Intellectual Property). Bottom line it is just too costly for a "small" guy to do the whole patent thing and then hope to be able to defend it, and get enough money back to at least break even. I rather avoid the whole problem, and simply don't worry about it. If somebody wants to copy/incorporate my ideas, go ahead... you'd be in a better position to negotiate with a law firm willing to take the case for a cut...

Last edited:

Great job and a very good idea .... you give me envy.

I'm serious.

- Thread starter

- #30

I made another prototype (photos here) and have been using it for the last 4-5 months. Still don't have the means to offer them for sale, so for now this remains a personal shaver:

You do awesome work man. The razor is very unique looking, that's why i like it.

That's an amazing looking razor!

Super cool.

Genius!

Those rare earth magnets are VERY strong ... and you've given me a super idea!

40x20x2mm magnet with a GEM blade on top and a Rolls Razor handle to hold in place. The angle of the pinch at the top of the Rolls Razor handle should be about the right angle to clamp the two together and the magnetism hold it all in place. In fact, a wider and shallower magnet would work for those hair dresser blades with spines.

I think I have just the right kit at home for a derived work.

Cheers! Great ideas.

Those rare earth magnets are VERY strong ... and you've given me a super idea!

40x20x2mm magnet with a GEM blade on top and a Rolls Razor handle to hold in place. The angle of the pinch at the top of the Rolls Razor handle should be about the right angle to clamp the two together and the magnetism hold it all in place. In fact, a wider and shallower magnet would work for those hair dresser blades with spines.

I think I have just the right kit at home for a derived work.

Cheers! Great ideas.

Scares me just looking at it!

My thoughts didn't quite pan out ...

I need to get a second magnet. The ones I'm using are strips/slabs of neodymium and when placed on a piece of metal, they like to jump to the middle of whatever it is they're magnetising (to). So, narrow strips (like 10mm deep) are too short for GEM blades; 40mm deep are too deep, covering the edge. Furthermore, the spines cause issues.

What I thought would be a simple case of a magnet on each side of a GEM with a Rolls Razor handle has not worked out. Conceptually, great ... something that can still work if the exact correct dimensions for the magnets can be procured for de-spined GEMs. Understand that Feathers are a slightly different size and so would require their own custom size.

Finally, removing the blade was a pain, even dangerous.

This concept with a metal frame to position the magnets is super! Perhaps thinner, a top and a base, using slab magnets would make a really good looking and safer razor?

Inspiring stuff!

I need to get a second magnet. The ones I'm using are strips/slabs of neodymium and when placed on a piece of metal, they like to jump to the middle of whatever it is they're magnetising (to). So, narrow strips (like 10mm deep) are too short for GEM blades; 40mm deep are too deep, covering the edge. Furthermore, the spines cause issues.

What I thought would be a simple case of a magnet on each side of a GEM with a Rolls Razor handle has not worked out. Conceptually, great ... something that can still work if the exact correct dimensions for the magnets can be procured for de-spined GEMs. Understand that Feathers are a slightly different size and so would require their own custom size.

Finally, removing the blade was a pain, even dangerous.

This concept with a metal frame to position the magnets is super! Perhaps thinner, a top and a base, using slab magnets would make a really good looking and safer razor?

Inspiring stuff!

Fascinating project. Keep refining it. Very creative.

- Thread starter

- #39

My thoughts didn't quite pan out ...

I need to get a second magnet. The ones I'm using are strips/slabs of neodymium and when placed on a piece of metal, they like to jump to the middle of whatever it is they're magnetising (to). So, narrow strips (like 10mm deep) are too short for GEM blades; 40mm deep are too deep, covering the edge. Furthermore, the spines cause issues.

What I thought would be a simple case of a magnet on each side of a GEM with a Rolls Razor handle has not worked out. Conceptually, great ... something that can still work if the exact correct dimensions for the magnets can be procured for de-spined GEMs. Understand that Feathers are a slightly different size and so would require their own custom size.

Finally, removing the blade was a pain, even dangerous.

This concept with a metal frame to position the magnets is super! Perhaps thinner, a top and a base, using slab magnets would make a really good looking and safer razor?

Inspiring stuff!

Awesome. Now you get why I liked this concept so much. Not perfect (yet), but there is great potential to the idea.

I have another idea of making a "top" plate, and using magnets to keep the top plate "pinching" holding the Feather blade in place, so then you remove/slide the top off, the blade would come off. Maybe one of these days I will have more time to tinker and try it out

The more I look at this (these) the more I like it! Very cool work indeed.

Similar threads

- Replies

- 1

- Views

- 643

- Replies

- 0

- Views

- 641