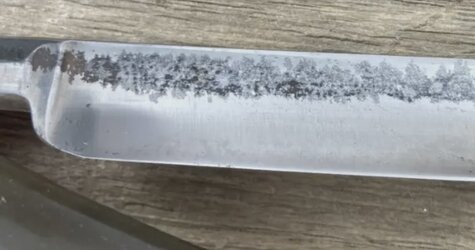

Put this one back in action. Probably the worst pivot hole I’ve come across in a blade. Oblong crooked, and oversized.

Attachments

-

1B610AA6-E048-4690-ABDE-CF6EFB701645.jpeg128.1 KB · Views: 46

1B610AA6-E048-4690-ABDE-CF6EFB701645.jpeg128.1 KB · Views: 46 -

A3426CD3-3795-4949-BEE3-CAE13DC367A6.jpeg87 KB · Views: 43

A3426CD3-3795-4949-BEE3-CAE13DC367A6.jpeg87 KB · Views: 43 -

B4ED181E-9D66-4E05-B38D-5087280F8BB1.jpeg83.2 KB · Views: 42

B4ED181E-9D66-4E05-B38D-5087280F8BB1.jpeg83.2 KB · Views: 42 -

2E855FDF-DC2D-4F68-91E5-3E3941EF2461.jpeg1.8 MB · Views: 42

2E855FDF-DC2D-4F68-91E5-3E3941EF2461.jpeg1.8 MB · Views: 42 -

CE35ADE5-D4D9-43DD-93E2-5B5CC730F9BA.jpeg2 MB · Views: 39

CE35ADE5-D4D9-43DD-93E2-5B5CC730F9BA.jpeg2 MB · Views: 39 -

CA3D28A8-CD09-481F-97DA-A42133A0391B.jpeg1.7 MB · Views: 36

CA3D28A8-CD09-481F-97DA-A42133A0391B.jpeg1.7 MB · Views: 36 -

D8A299F7-9D33-4719-B432-9D932DA96582.jpeg1.9 MB · Views: 40

D8A299F7-9D33-4719-B432-9D932DA96582.jpeg1.9 MB · Views: 40 -

637A6DE7-8D54-47CE-B12B-51E2A0FF59F3.jpeg1.1 MB · Views: 48

637A6DE7-8D54-47CE-B12B-51E2A0FF59F3.jpeg1.1 MB · Views: 48