Hi, I got a set of ebay beaters (SRs) to try my hand at honing. On getting my hands on two of these, however, I'm leaning more to restore them fully.

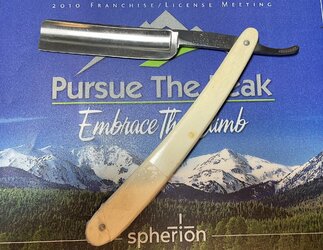

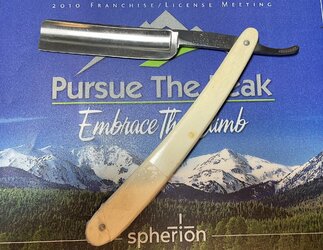

One is a Bismarck made by Ludwig Baer (Solingen, Germany) with bone scales. Another is a D.B. Special made by Wm. Dueltgen (New Jersey) with either bone or celluloid scales. Unfortunately, both of them have cracked scales (one of my own making). The blades seem in solid condition with no visible (under magnification) rust or pitting. Seeing the condition of the blades I'm tempted to either get them re-scaled professionally in similar scales or do them myself. Both are between 5/8 and 11/16.

a) are they worth re-scaling professionally? How much would this even cost? Who can do such a thing (USA)?

I looked into Maggards - their services are reasonable, but they have limited set of replacement scales. Razor Emporium seems to have only acrylic scales and cost is $$

b) Should I try to do this on my own? I tried my hand at changing scales on two other razors and frankly disappointed in myself. I can (nay should) ask for more help if I try this on my own.

Are there other options? Perhaps get a set of Dovo replacement scales? A set seems to run for $35 on the bay, but they're acrylic not bone.

One is a Bismarck made by Ludwig Baer (Solingen, Germany) with bone scales. Another is a D.B. Special made by Wm. Dueltgen (New Jersey) with either bone or celluloid scales. Unfortunately, both of them have cracked scales (one of my own making). The blades seem in solid condition with no visible (under magnification) rust or pitting. Seeing the condition of the blades I'm tempted to either get them re-scaled professionally in similar scales or do them myself. Both are between 5/8 and 11/16.

a) are they worth re-scaling professionally? How much would this even cost? Who can do such a thing (USA)?

I looked into Maggards - their services are reasonable, but they have limited set of replacement scales. Razor Emporium seems to have only acrylic scales and cost is $$

b) Should I try to do this on my own? I tried my hand at changing scales on two other razors and frankly disappointed in myself. I can (nay should) ask for more help if I try this on my own.

Are there other options? Perhaps get a set of Dovo replacement scales? A set seems to run for $35 on the bay, but they're acrylic not bone.

Last edited: