- Thread starter

- #21

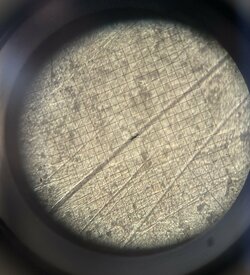

The striation at the bevel after the eef 8k looks terrible. However, if you use light pressure, and only do edge leading strokes it can set the edge up nicely for a suitable finisher.Stepped up to the EEF. It feels like garbage. Fair enough, that‘s apparently par for the course. With light pressure, start with 5 laps and a scope. Not looking good already.

You actually need a high magnification level to see what is happening.

I would also skip the 1200 to rule out this plate. You don't need it. The 8k cuts really fast.

I have now honed multiple razor, and the results are consistently good.

8k EEF edge

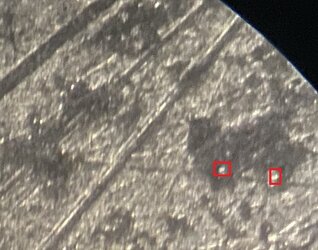

After two minutes on a jnat with tomo slurry

Part of the edge that was subjected to some larger diamonds. This will not effect the shave.