rbscebu

Girls call me Makaluod

The purpose of this thread is to obtain other's experience of honing with their Adaee #12000 Cnat whetstone, if you have/had one. There are plenty of other Cnats out there but I would prefer if this thread is restricted to the Adaee #12000 whetstone.

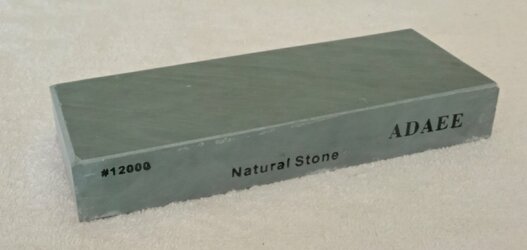

I received my Adaee #12000 a little over five months ago (about US$40 incl. shipping). It is 200mm x 75mm x 30mm with an SG = 2.77. Here is as received:

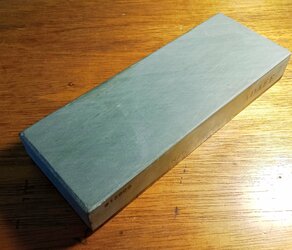

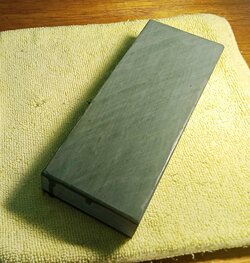

After lapping flat and quite a few honing sessions, it is now looking like this:

I have found this whetstone to be noticeably finer than my 10k Jsynth but a very slow cutter. I also consider it a splash and go type of stone with almost no water absorption.

I have only used this whetstone as a finisher using water and lather. The whetstone does not appear to self-slurry so the underside is used with a very light slurry developed with a 1k diamond plate. The topside is used without any slurry and has developed a slight burnishing of about 50%.

For cutting speed, I find it takes about 2 to 3 time the number of laps that I would normally require when using 1μm lapping film (coming from 3μm film). This means that a lot of work is required with my harder stainless steel SRs. For me, all this work is worth it.

It has taken me quite a while to learn how to get the best out of this Adaee but I feel that I am about there. My stainless steel SRs make up about a third of my stable. On these stainless steel SRs, this Adaee #12000 gives me an edge that well matches my 0.1μm diamond pasted balsa strop edges and a finish that is more comfortable to shave with. The bevel surface from the Adaee has an ever-so slight hazy finish compared to the mirror finish from the balsa.

With carbon steel SRs, I find edges from this Adaee not quite up to the keenness of the pasted balsa and having about the same shaving comfort level.

I am now at the point where I will be finishing all of my stainless steel SRs on this Adaee #12000. My cardon steel SRs will continue to be finished on diamond pasted balsa or vintage coticule.

I received my Adaee #12000 a little over five months ago (about US$40 incl. shipping). It is 200mm x 75mm x 30mm with an SG = 2.77. Here is as received:

After lapping flat and quite a few honing sessions, it is now looking like this:

I have found this whetstone to be noticeably finer than my 10k Jsynth but a very slow cutter. I also consider it a splash and go type of stone with almost no water absorption.

I have only used this whetstone as a finisher using water and lather. The whetstone does not appear to self-slurry so the underside is used with a very light slurry developed with a 1k diamond plate. The topside is used without any slurry and has developed a slight burnishing of about 50%.

For cutting speed, I find it takes about 2 to 3 time the number of laps that I would normally require when using 1μm lapping film (coming from 3μm film). This means that a lot of work is required with my harder stainless steel SRs. For me, all this work is worth it.

It has taken me quite a while to learn how to get the best out of this Adaee but I feel that I am about there. My stainless steel SRs make up about a third of my stable. On these stainless steel SRs, this Adaee #12000 gives me an edge that well matches my 0.1μm diamond pasted balsa strop edges and a finish that is more comfortable to shave with. The bevel surface from the Adaee has an ever-so slight hazy finish compared to the mirror finish from the balsa.

With carbon steel SRs, I find edges from this Adaee not quite up to the keenness of the pasted balsa and having about the same shaving comfort level.

I am now at the point where I will be finishing all of my stainless steel SRs on this Adaee #12000. My cardon steel SRs will continue to be finished on diamond pasted balsa or vintage coticule.