I have a 400x Chosera that works wonders. I had a Nubatama 180 that was nice but it took forever to soak and longer to dry out so I sorta threw it out when I got ticked off at it one day. But it worked well for speeding up heavy stock removal without leaving huge scars/gashes, etc.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Heavy grinds, Chip Removal, etc. Heavy lifting hone selection.

- Thread starter SliceOfLife

- Start date

With oil-stones, a worn medium India followed by a worn soft Arkansas has always suited me well, although more lately I've been playing with synth water-stones, where a Beston 500 followed by a Bester 1200 seems to be the ticket.

Last edited:

I have used medium and fine India stones as repair or repro filling an abused or gd condition razor for years.

You can condition them on one side with silicone carbide loose grit to cut finer and more shallow as you like .cheers.

As a coarse Waterstone I use the chosera 400 or a shapton 320 or even a very worn in dmt8c.

Use what the situation dictates?

You can condition them on one side with silicone carbide loose grit to cut finer and more shallow as you like .cheers.

As a coarse Waterstone I use the chosera 400 or a shapton 320 or even a very worn in dmt8c.

Use what the situation dictates?

- Thread starter

- #24

I've read many people caution against diamond plates. They've suggested that the scratch pattern is a bit deeper than an equal grit hone and there fore harder to hone out later. Any thoughts?

A lot of people stated their suspicions as facts about things like Diamond plates. They don't cut deep, but they cut aggressively; so they don't thin the way less aggressive hones can. Great trait for a hone that will be followed. Not great as a final hone in my opinion. To put it simply, a shave off a DMT 8k is probably worse than a shave of a 4k JIS or Norton 8k. But the edge off a DMT 8k is MUCH more easily refined by a finisher than off either of those.

A lot of people stated their suspicions as facts about things like Diamond plates. They don't cut deep, but they cut aggressively; so they don't thin the way less aggressive hones can. Great trait for a hone that will be followed. Not great as a final hone in my opinion. To put it simply, a shave off a DMT 8k is probably worse than a shave of a 4k JIS or Norton 8k. But the edge off a DMT 8k is MUCH more easily refined by a finisher than off either of those.

Zactly. That is why I can bash a blade into shape using my 600 DMT, and then polish out the scratches and continue honing with a slurried coticule. Pretty easily, actually.

I used an Atoma 400# to remove a toothed edge today. I had never went below 1k before. Perhaps I need to look at a DMT600 soon. The 400 was pretty rough but it got the job done and fast. Deffinately not for the faint of heart though!

Slash McCoy

I freehand dog rockets

I have used cheap diamond hones from Harbor Freight for very rough work, but now I use sandpaper, mostly. I have gone as far down as 60 grit in extreme cases. Just stop when you need to stop, and start a progression from there. Ideally there is just a faint trace of the original fault left, when moving up from your coarse starting grit. By the time you get to a normal bevel setting grit, the fault should be long gone. OH NO, HORRORS! 60 grit? You will ruin that razor! OMG I do hope you tape the spine or lift it off the paper! Well, no. That would be a serious error. It's just steel. Steel that must be removed anyway, doesn't care if you scratch the aitch ee double hockeysticks out of it. Let the progression do its job.

As for diamond hones scratching deeply, yes this can be a real thing. When new, most diamond plates have particles that stand proud of the surface. These ought to be knocked down by vigorously honing some hard stainless kitchen knives or similar, for best results. Once the irregular crystals are knocked off, they work just fine on razors as long as you are aware of their limitations. I mostly like sandpaper because of the wide choice of grits and the immense honing/grinding area I can give myself.

As for diamond hones scratching deeply, yes this can be a real thing. When new, most diamond plates have particles that stand proud of the surface. These ought to be knocked down by vigorously honing some hard stainless kitchen knives or similar, for best results. Once the irregular crystals are knocked off, they work just fine on razors as long as you are aware of their limitations. I mostly like sandpaper because of the wide choice of grits and the immense honing/grinding area I can give myself.

Low grit mediums are fine. The "profesionals" say no but they use them all day long. They dont want you to know that if used correctly like anything else they are fine. Saw a video of a famous guy, he made a rqzor for a customer. The edge kept chipping. He said the guy used a coarse hone and then proceeded to use a belt sander to take the chips out! Hmm. I wonder what grit the belt sander was. Theres a LOAD of bs out there. Dont take anybodies word for it. Prove or disprove it yourself is all i will say.

- Thread starter

- #29

So I used my 12x2.5" Crystolon coarse/fine oilstone to fix the problem with this ERN ATOR. It had been honed with the heel off the stone for a long time and was kind of wedge shaped (5/8" at toe and 6/8" at heel). Took about 8-9 minutes, which didn't feel especially slow or fast... but it was definitely easy. No nonsense. No clogging of the stone. Just hit it with more oil here and there and grind away with as much pressure as I liked. Basically... I didn't feel like I sacrificed anything vs using a 220 dmt or 800 King, and I got this hone effectively free (came in a lot I bought for another hone). Perfectly suitable heavy-lifting razor hone that doesn't bring more than what it costs to ship on eBay. Not a bad solution to some rough geometry fixes.

I expect the razor to be a winner. Reminds me of some of my nicer puma's in shape and steel.

The picture is a before to show how bad the heel was. My phone is dead and being RMA'ed at the moment and I'm not gonna disassemble my microscope camera to take an after picture, but it's got proper geometry now, so just picture that.

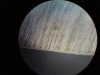

The scope shot is the edge the fine side of the crystolon leaves. It shaves arm hair well enough, but there's a definite bite to it that you have to pull it through the hair forcibly. Probably in the 400-600grit range... but more tooth than most waterstones leave.

I expect the razor to be a winner. Reminds me of some of my nicer puma's in shape and steel.

The picture is a before to show how bad the heel was. My phone is dead and being RMA'ed at the moment and I'm not gonna disassemble my microscope camera to take an after picture, but it's got proper geometry now, so just picture that.

The scope shot is the edge the fine side of the crystolon leaves. It shaves arm hair well enough, but there's a definite bite to it that you have to pull it through the hair forcibly. Probably in the 400-600grit range... but more tooth than most waterstones leave.

Attachments

Last edited:

- Thread starter

- #30

Similar threads

- Replies

- 63

- Views

- 5K