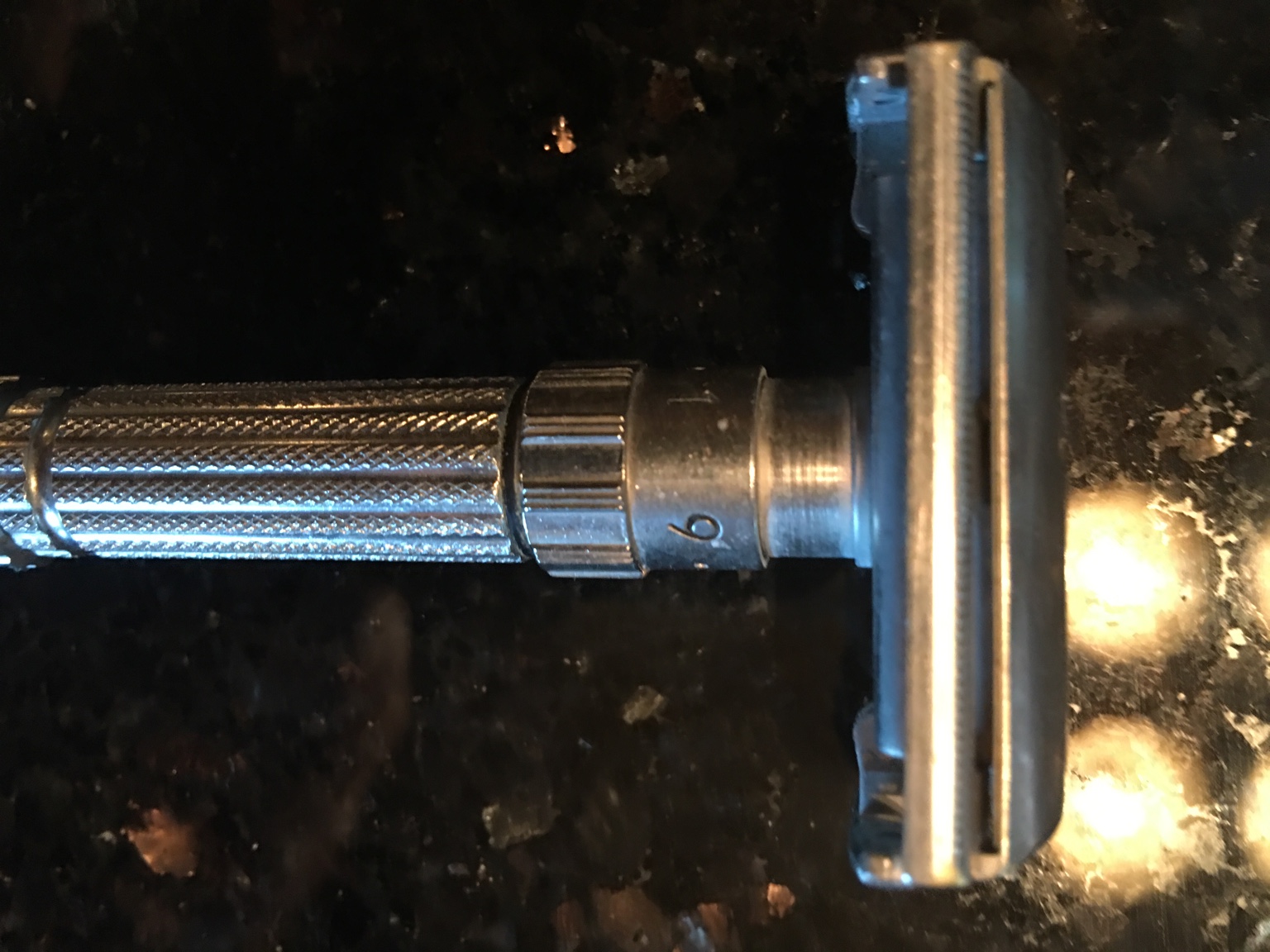

I have a fatboy and love using it but just noticed the blade gap is uneven. Is this common? How do I fix it?

I was going to post pics but don't know how.

Also what oil should I use on my adjustables.

Thanks for the advice.

I was going to post pics but don't know how.

Also what oil should I use on my adjustables.

Thanks for the advice.