- Thread starter

- #21

Mick were you able to salvage all the relays and wiring? Looks fantastic!

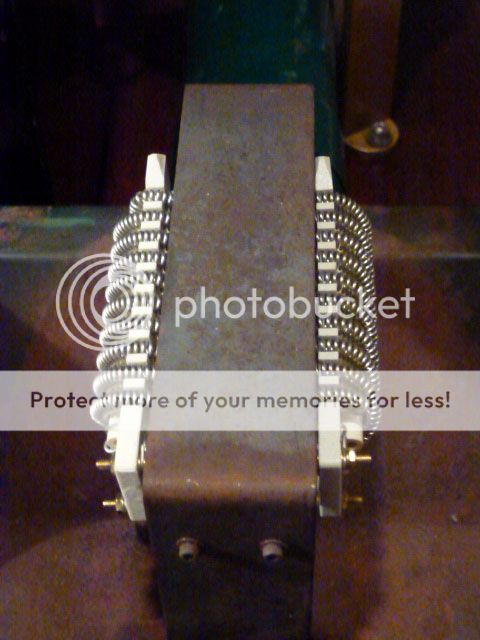

All was fine except for the heater rheostats which were replacements (not correct and not HD enough so burned up... they were light fixture dimmers and not up to the 14 amp X 2 draw of the heating elements).

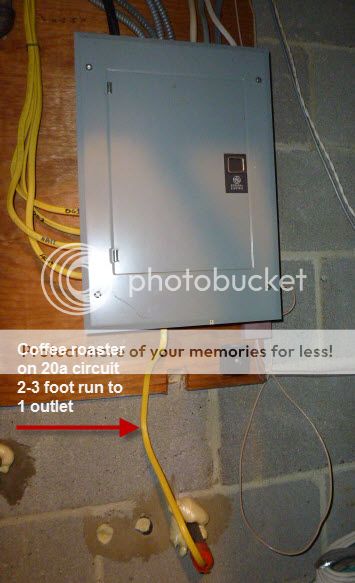

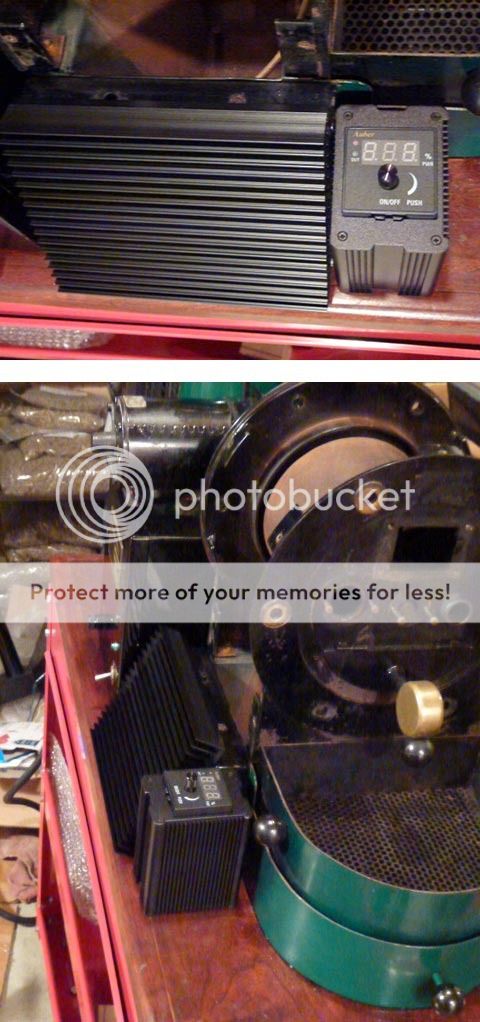

I've ordered an 80 amp 10kw rheostat that is 220V but I can feed 220 in and take both lines out separately to each heater (110). That one should be MORE than HD enough to get the roaster started using manual controls I am hoping to get some thermocouples into the face of the roaster for BT (bean mass temp) and ET (roasting basket ambient temp), then feed these to another Artisan interface board like I did on my hottop roaster.

I don't want to canalize the hottop as it works so nicely so I need another set of cards and a housing for the new "bits"

Last edited: