Having a soft spot for older film cameras and especially rangefinders from the 60's, 70's and 80's, I from time to time take the chance and buy unknown, untested cameras "in the wild" at flea markets and garage sales. Have found many deals this way and with a little bit of work mixed with a can-do attitude and the ability to say oh well if things don't work out, anyone can do this.

I will say, I have thrown out cameras while learning and have not had any training beyond a few videos and conversations about specific cameras. If it is a camera you care about, can't replace easily, or do not want the possibility of screwing things up more ( aka fubar), then send it to a trained professional. I learned by doing. More importantly, I have learned how NOT to do certain things...

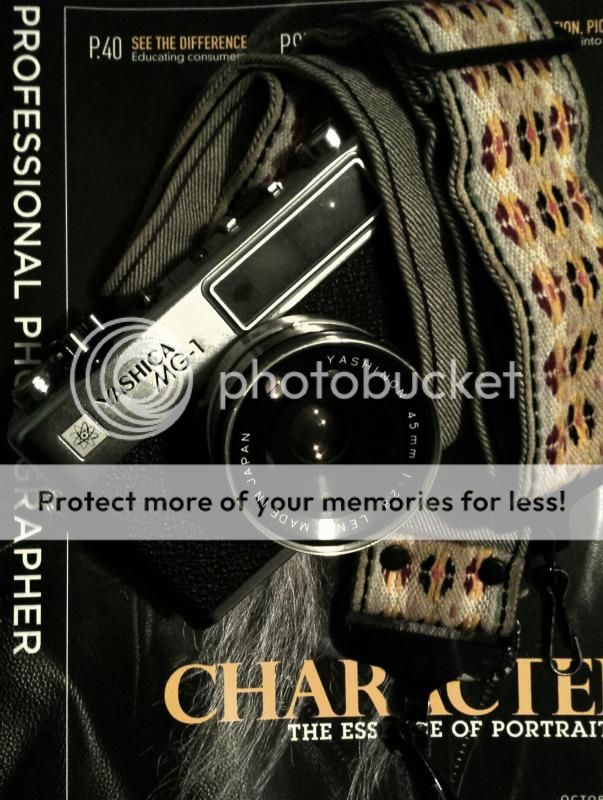

This past Sunday I picked up a nice looking Yashica MG -1 rangefinder for $5. It functioned mechanically, wasn't dented or beat up, and had minor corrosion in the battery compartment. But, aperture blades were clean, functioned smooth, glass was in great shape, and everything was there. So, for the price of a Draft brew I decided to take the chance.

Knowing the camera is the first step to buying like this. The MG -1 is the baby brother to the much more popular Yashica Electro 35 series. It is the same size and shape, but has some different features. It was nearly half the price of the GSN when new.

This camera has a cds cell inside the lens ring, the little eye above the lens, for metering. This one was nice and clean. Nice thing about this style is it will meter through any filters you put on. Yashica users will likely be familiar with the "POD" or Pad of Death. It's a little 2 mm thick piece of rubber that deteriorates into some sort of petroleum by product type goo and is essential to keeping everything in proper adjustment. If it is worn out, when you wind on the film you will hear a loud "clunk" and that isn't good. This one went clunk. I already had a replacement pad with self adhesive backing. But, any durable material that is exactly 2 mm thick can be used. I've heard that flexible magnet, Tupperware lid, and any other hard-ish material being used.

Next thing about old cameras is the batteries. This one was designed for a 5.7v mercury cell, well, since those are pretty much extinct, finding a modern replacement is important. I have a good supply available through my work of 6v alkaline cells that work well enough, though it does throw the meter off about 1/3 of a stop. 4 LR44 batteries can also be taped together to work. There are even adapters available for not much money.

Here is the camera...

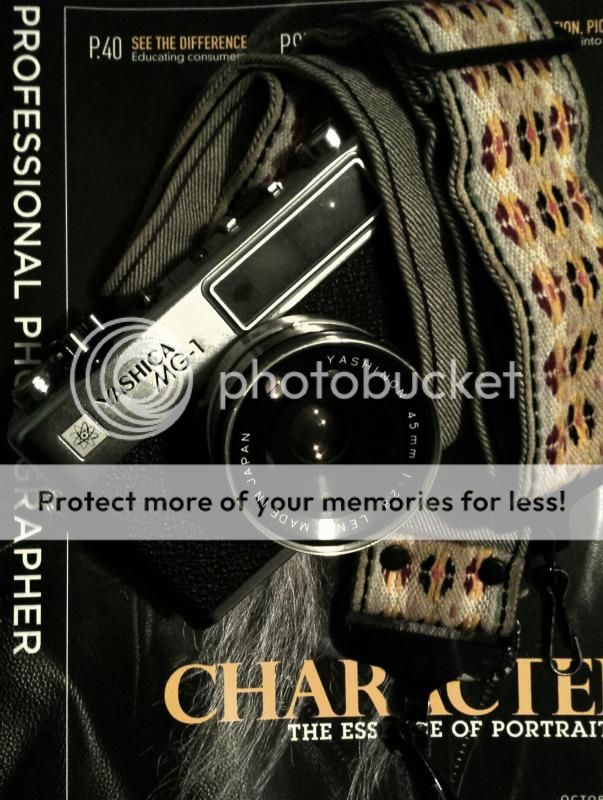

Here next to my Electro 35 GSN For comparison. ..

First and obvious thing to do was tackle the corrosion in the battery compartment. Seemed to be mostly contained to the screw cap. The clean one is from my GSN to compare if this one will even make suitable contact.

A look inside the battery tube shows that there is a small amount of corrosion near the base of the spring. This could be troublesome, could be nothing...

So I spray a bit of foaming electrical contact cleaner in there to help it out. Swab out the excess and leave it to do its thing.

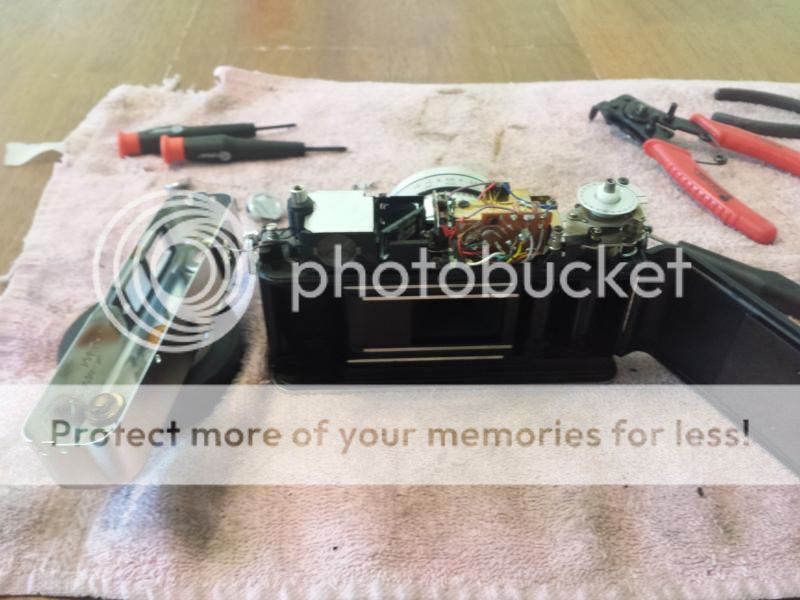

Next is to tackle the POD. This camera is laid out differently than the GSN I am familiar with and locating the POD is entirely new for me. There isn't much info out there about these specific cameras, everybody wants the GSN. So after some searching to no avail, I decide to just dive in and snoop around.

To pull the top plate, use a small spanner to remove the advance lever, under it are a wave washer and backing plate. Next is to open the back (tape over the edge of the door so it doesn't latch closed) and hold the film rewind spur to unscrew the rewind knob. Next is three small screw around the edge of the top plate. Lift carefully, there is a tiny wire that connects the hot shoe to the electronics. It a pain if it breaks.

More in next post

I will say, I have thrown out cameras while learning and have not had any training beyond a few videos and conversations about specific cameras. If it is a camera you care about, can't replace easily, or do not want the possibility of screwing things up more ( aka fubar), then send it to a trained professional. I learned by doing. More importantly, I have learned how NOT to do certain things...

This past Sunday I picked up a nice looking Yashica MG -1 rangefinder for $5. It functioned mechanically, wasn't dented or beat up, and had minor corrosion in the battery compartment. But, aperture blades were clean, functioned smooth, glass was in great shape, and everything was there. So, for the price of a Draft brew I decided to take the chance.

Knowing the camera is the first step to buying like this. The MG -1 is the baby brother to the much more popular Yashica Electro 35 series. It is the same size and shape, but has some different features. It was nearly half the price of the GSN when new.

This camera has a cds cell inside the lens ring, the little eye above the lens, for metering. This one was nice and clean. Nice thing about this style is it will meter through any filters you put on. Yashica users will likely be familiar with the "POD" or Pad of Death. It's a little 2 mm thick piece of rubber that deteriorates into some sort of petroleum by product type goo and is essential to keeping everything in proper adjustment. If it is worn out, when you wind on the film you will hear a loud "clunk" and that isn't good. This one went clunk. I already had a replacement pad with self adhesive backing. But, any durable material that is exactly 2 mm thick can be used. I've heard that flexible magnet, Tupperware lid, and any other hard-ish material being used.

Next thing about old cameras is the batteries. This one was designed for a 5.7v mercury cell, well, since those are pretty much extinct, finding a modern replacement is important. I have a good supply available through my work of 6v alkaline cells that work well enough, though it does throw the meter off about 1/3 of a stop. 4 LR44 batteries can also be taped together to work. There are even adapters available for not much money.

Here is the camera...

Here next to my Electro 35 GSN For comparison. ..

First and obvious thing to do was tackle the corrosion in the battery compartment. Seemed to be mostly contained to the screw cap. The clean one is from my GSN to compare if this one will even make suitable contact.

A look inside the battery tube shows that there is a small amount of corrosion near the base of the spring. This could be troublesome, could be nothing...

So I spray a bit of foaming electrical contact cleaner in there to help it out. Swab out the excess and leave it to do its thing.

Next is to tackle the POD. This camera is laid out differently than the GSN I am familiar with and locating the POD is entirely new for me. There isn't much info out there about these specific cameras, everybody wants the GSN. So after some searching to no avail, I decide to just dive in and snoop around.

To pull the top plate, use a small spanner to remove the advance lever, under it are a wave washer and backing plate. Next is to open the back (tape over the edge of the door so it doesn't latch closed) and hold the film rewind spur to unscrew the rewind knob. Next is three small screw around the edge of the top plate. Lift carefully, there is a tiny wire that connects the hot shoe to the electronics. It a pain if it breaks.

More in next post

Last edited:

Great work, Xander, and thank you for the detailed posts. I hope you enjoy the camera.

Great work, Xander, and thank you for the detailed posts. I hope you enjoy the camera.