Hello I have a friend who gave me a synthetic ruby hone, like a 1 x 4 inch size that he doesn't need. Now ruby is supposed to be carborundum and rated at 9 hardness scale. Im thinking of using this as a super hard tomo to raise base stone slurry on my harder jnats. Does this sound feasible or any better suggestion Im all ears. Thanks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Synthetic ruby stone

- Thread starter buca3152

- Start date

Ruby is actually Aluminum Oxide, and could also be called ceramic. Also a hardness of 9. If it's a sintered stone (not held together by a binder) it should be comparable to a Spyderco Fine or Ultra Fine (depending on many factors) and **shouldn't** break down if used as a slurry stone. I look forward to hearing how it works for you.

- Thread starter

- #3

Most of them that I've seen are sintered synthetic 'ruby' or corundum. Generally - they're sold as being 3k or so.

I had one - was a decent set up stone before the Beryl stone.

On oil, it was fast - really fast. Like - stupid fast. The stone loaded quickly and it wasn't easy to clear off.

There are a lot of them out there, most are relatively inexpensive. I'm not sure if they're all the same. Testing is the only way to find out.

I had one - was a decent set up stone before the Beryl stone.

On oil, it was fast - really fast. Like - stupid fast. The stone loaded quickly and it wasn't easy to clear off.

There are a lot of them out there, most are relatively inexpensive. I'm not sure if they're all the same. Testing is the only way to find out.

Really? They're sintered? I always thought it was just a gimmick for a red corundum hone to claim it had "Rubys" as the abrasive. I may have to try one now. Sounds neat.

I don't know if every ruby hone is sintered, a lot of this stuff comes out of China and who knows what that stuff is.

The good stones used for mold polishing are definitely sintered man-made ruby xls or bits or whatever.

The one I had was weird - but fun. the slabs for polishing are alleged to be 3k - thats a US grit I think, not JIS.

There are lower grit ruby stones too... not sure what they're for, I seem to remember maybe they're used to deburr molds?

I forget - I looked all this stuff up when I got mine.

Cut like a demon with oil, slower with water. Lapped pretty easily. Mine was from China - who knows what it really was.

The good stones used for mold polishing are definitely sintered man-made ruby xls or bits or whatever.

The one I had was weird - but fun. the slabs for polishing are alleged to be 3k - thats a US grit I think, not JIS.

There are lower grit ruby stones too... not sure what they're for, I seem to remember maybe they're used to deburr molds?

I forget - I looked all this stuff up when I got mine.

Cut like a demon with oil, slower with water. Lapped pretty easily. Mine was from China - who knows what it really was.

I'm was thinking of the vintage barber hones that had "Ruby" or "The Ruby Hone" or similar labels.

Nah - those are different.

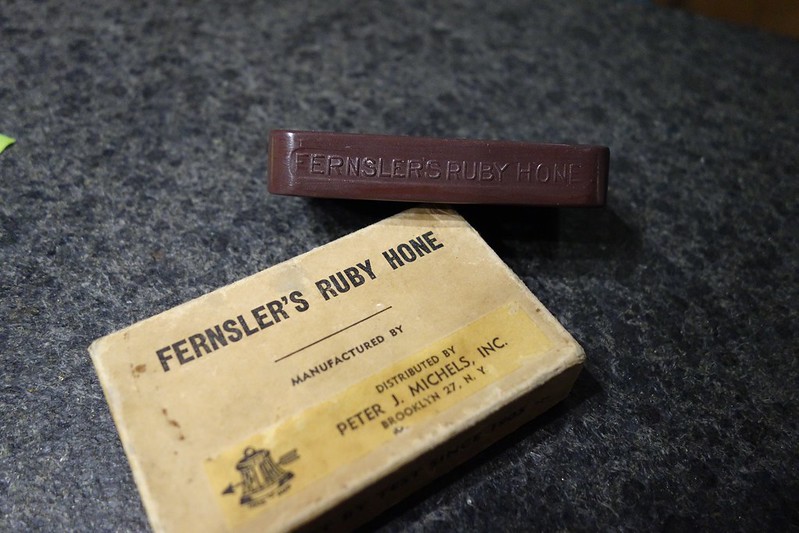

One of them is alleged to quite good - Fernslers Ruby Hone, or something like that.

One of them is alleged to quite good - Fernslers Ruby Hone, or something like that.

Nah - those are different.

One of them is alleged to quite good - Fernslers Ruby Hone, or something like that.

Keith Did you ever tried this one ?

Last edited:

Nope - never tried one of those - I did have another hone that was shellac though. Was a PITA to lap.

Fairly good stone - feels weird in the hand.

Might pick one of those Fernsler's up up someday though.

Fairly good stone - feels weird in the hand.

Might pick one of those Fernsler's up up someday though.

Last edited:

Its one of the nicest ones around, very comfortable shave....leaves a very shiny edge....

One of the stones around i often take with me travelin...

One of the stones around i often take with me travelin...

- Thread starter

- #12

Here it is. I lapped it. Supposed to come from an hand engraver who used to work in lower manhattan. Thats the story and I didnt buy it, it was given to me. I will test it out and see. I lapped it rather quickly on an atoma 140, its small so it went fast. It scratched my hardest stone which is an ozuku asagi.

Yeah if it's actually synthetic ruby I'd expect it'd scratch anything except a diamond.

- Thread starter

- #14

Sounds promising! What kind of edge do you get from the slurry? Like a DS Slurry or more like a Tomo Slurry?

- Thread starter

- #16

Dn slurry is coarser so cuts more than slurry such as this. What i like about this is it is much harder than any stone I have so its my go to when i want to raise fine base stone slurry. I used it once on a mediumhard asagi. I just ran the ruby stone on my ozuku asagi which is my hardest stone and it raised a fine slurry rather quickly. As opposed to 100 plus laps with an ozuku tomo. Much faster. I will say that having used base stone slurry like this has brought me great edges so Im thinking this is just a faster way of getting the slurry. I will test some edges and continue to report what I find.

Last edited:

I've found that coarser slurry doesn't neccessarily cut faster than finer slurry.

Incremental tracking a scratch pattern on a blade showed finer slurry cutting faster and more efficently.

Doesn't mean that happens all the time, just means that coarse slurry isn't always faster.

Is your ruby 'glassy' or 'plasticy' feeling? One of the two is supposed to have more friable AlOx particles.

Incremental tracking a scratch pattern on a blade showed finer slurry cutting faster and more efficently.

Doesn't mean that happens all the time, just means that coarse slurry isn't always faster.

Is your ruby 'glassy' or 'plasticy' feeling? One of the two is supposed to have more friable AlOx particles.

- Thread starter

- #18

It feels glassy. It works fast at raising the slurry, friable or not I dont know and will keep an eye out as if it isnt, the particles may cause chips. It is very very early to say whether this is viable or not. So far so good though and only 2 stones ad hones on it. Its hard and although I agree about big differences in stones, the size of the particles will have some affect on the finished edge as larger will tend to cut and scratch more. Generally and there are variables there.

Last edited:

- Thread starter

- #19

After some time using I find this works wonderful with all of my stones. Lately Ive been using chosera 1k, striped iyoto, hideriyama suita and a finisher. No naguras or other tomos except for a small rub of uchi half way through the last slurry on the finisher, just raising very fine base stone slurry on each. Its working GREAT for me, I haven't missed an edge since I started using this. I have not seen any particles getting lost in the moix from the ruby stone, so far so good.

That's about all a guy can ask for. I'm glad things are working.

Similar threads

- Replies

- 2

- Views

- 552

- Replies

- 63

- Views

- 5K