Hi all,

I'm interested to find out what methods you guys use to thin down that huge spine on the GD's ?

Mark

I'm interested to find out what methods you guys use to thin down that huge spine on the GD's ?

Mark

Why don't folks grind down the thick spines on a Maestro Livi?

Because they don't have to.

Why dont they grind down the big spines on a Filarmonica?

Because they don't have to.

Etc, etc.....

Do it if you WANT to, but there is no NEED to do so.

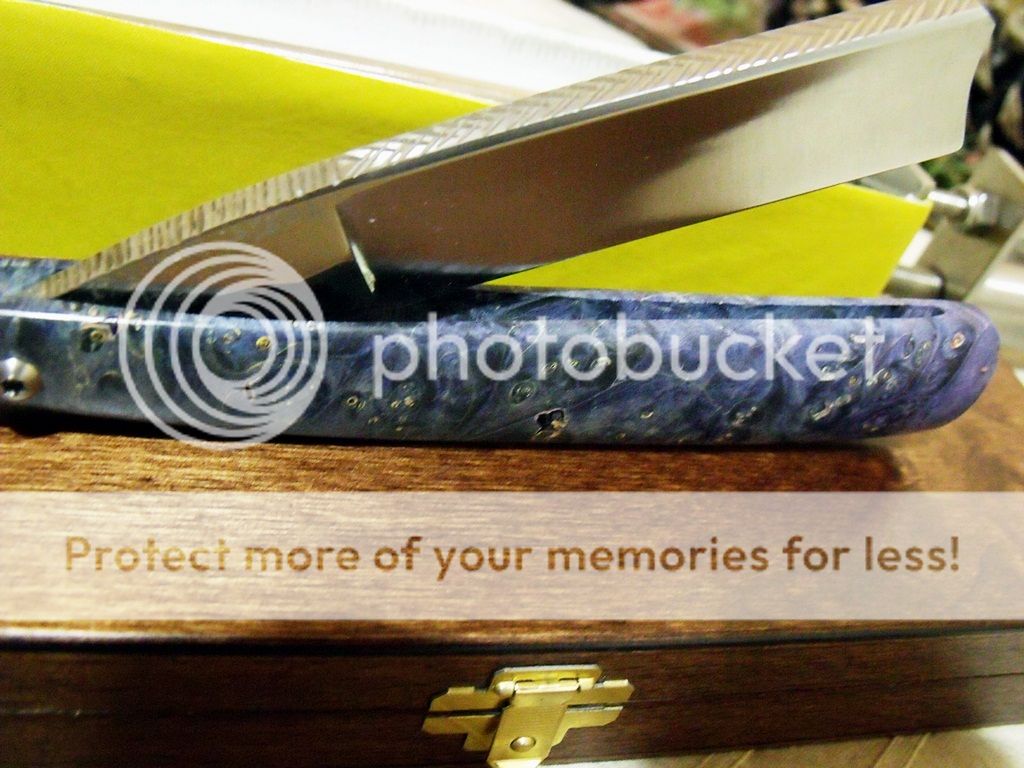

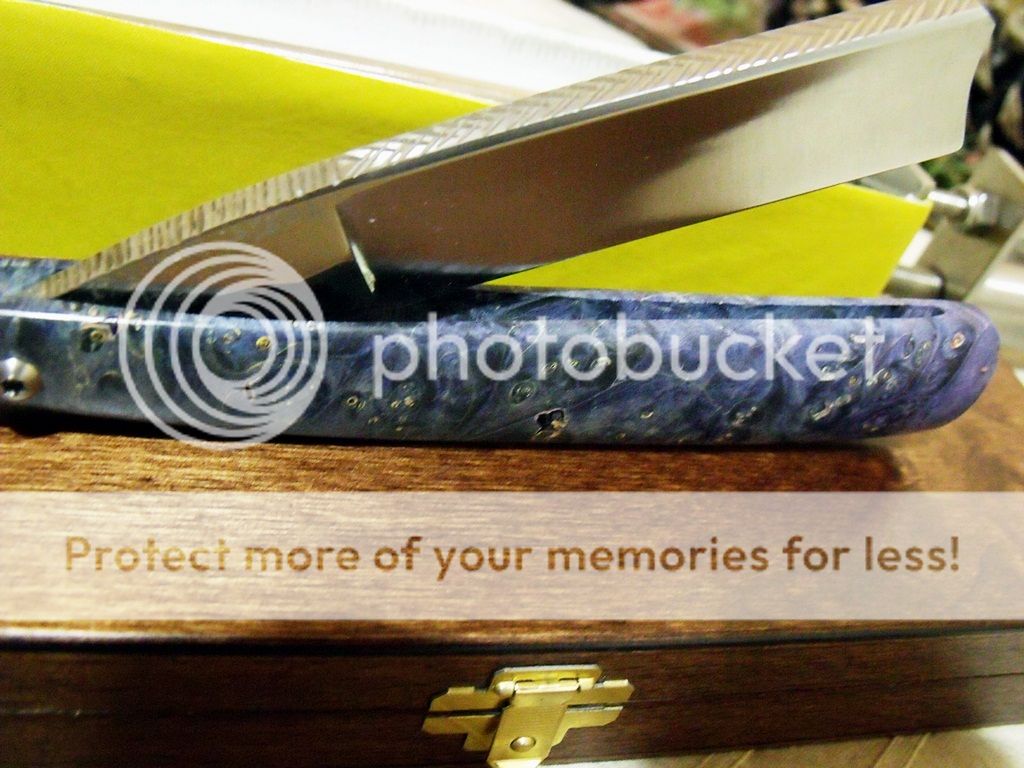

What I've been doing is scuffing it on a 325 DMT to check for flatness. (if necessary I'll work it on the DMT till its flat) Then, depending on how close it is to the angle I want I'll either take the dremel to it with a sanding wheel and then smooth it out on the DMT, or just work it on the DMT. (It's almost impossible to get anything straight/flat over any length with just a dremel, there are usually dips and waves left)

Though while I'm working it on the DMT for thinning purposes, I'll actually tape the blade edge so I'm not taking material off it as well.