Pressure question...

Being new to razor honing, but with a lot of knife honing experience, I find a couple of my biggest challenges are figuring how much pressure to apply, and when to switch stones.

Anyway someone might be able describe these two items? I mean the weight of the razor, or "hoverhand" (love that description BTW) is a good descriptor, so for pressure, would it be pencil eraser, or scratch off ticket, or...?

Likewise on the switching stones...

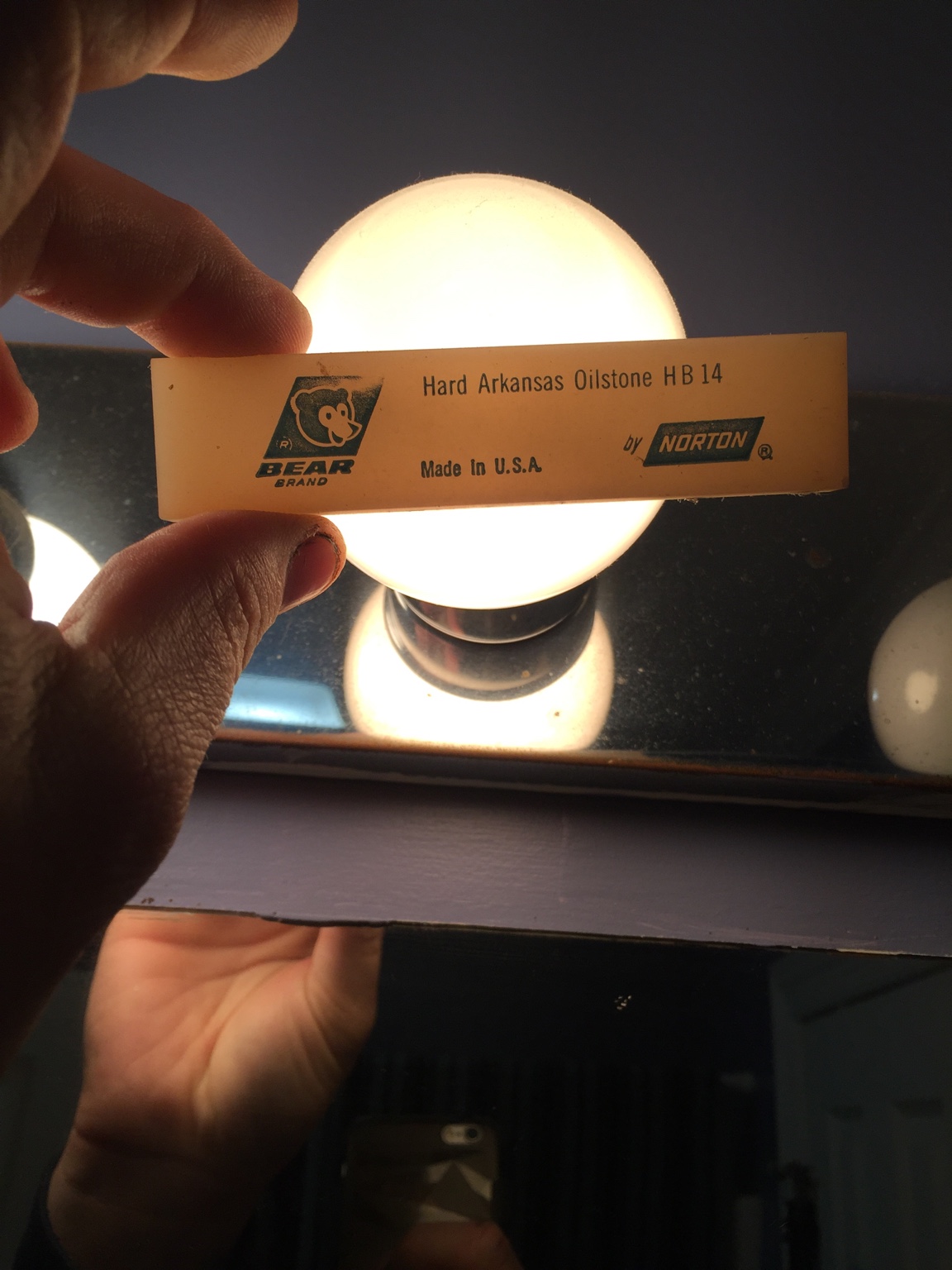

I suppose I should find me one of those nobrainer stones as well, suggestions?

Thanks.

2. They're fast. People call them slow because they only learned the internet method of razor honing... I call it the "hoverhand" technique. You know what I mean. Sharpening requires pressure... controlled, balanced, PURPOSEFUL pressure; but pressure. I'm sure a lot of guys polish the hell out of their Arkansas, then run razors around on them with the weight of the razor and boggle at how slow the stone cuts. They are PENETRATIVE cutters. You have to PUSH the metal and the stone together to get it to cut. On a well-worn arkansas there are not big old honking chunks of abrasive sticking up (or rolling around) and banging up your razor. YOU are the mechanism of the metal removal... not slurry and not the stone surface. Your force directly translates into metal being removed from the tool.

...

4. They are easy to use. Managing pressure isn't hard. Every time you sharpen anything, you get better at it. You find it challenging or don't feel confident at it? Do it more. Keep a nobrainer stone around (like a Thuri or a Jsynth) for comparison. The ark edge isn't as sharp as the thuri/synth edge? You need more practice.

.

Being new to razor honing, but with a lot of knife honing experience, I find a couple of my biggest challenges are figuring how much pressure to apply, and when to switch stones.

Anyway someone might be able describe these two items? I mean the weight of the razor, or "hoverhand" (love that description BTW) is a good descriptor, so for pressure, would it be pencil eraser, or scratch off ticket, or...?

Likewise on the switching stones...

I suppose I should find me one of those nobrainer stones as well, suggestions?

Thanks.