This time were bringing you something a little different, higher quality with performance options. Hiromoto Aogami Super Steel knives represent a great value to price ratio, add in some extra work and they become truly exceptional knives destined to become family heirlooms.

Hiromoto Tenmi-Jyuraku Aogami Super Steel (AS) Series

Santoku - 190mm available

Gyuto - 210mm, 240mm & 270mm available

Knife Features:

Core Steel Type - Hitachi Aogami Super Steel - 1.40-1.50 Carbon, 0.30-0.50 Chromium, 2.00-2.50 Tungsten

Cladding Steel Type - 420J1 Stainless

Stock Handle Black Staminawood

Package Options:

1. Sharpening Package ($35 Value) = Edge Sharpened, Spine/Choil Smoothed

Example - See above stock photos

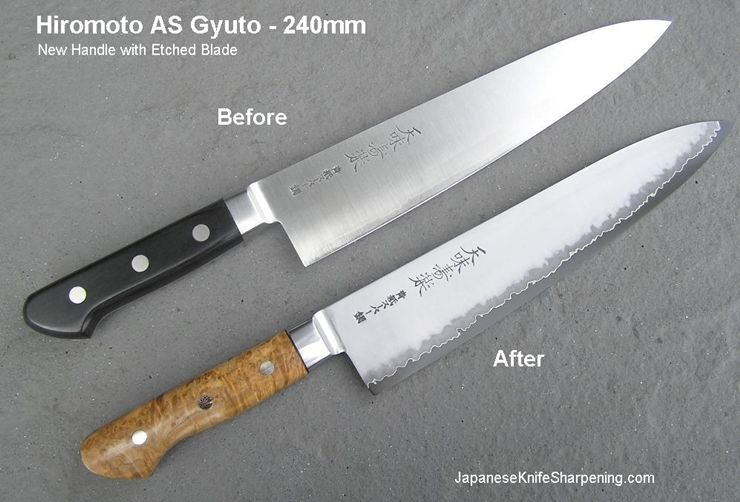

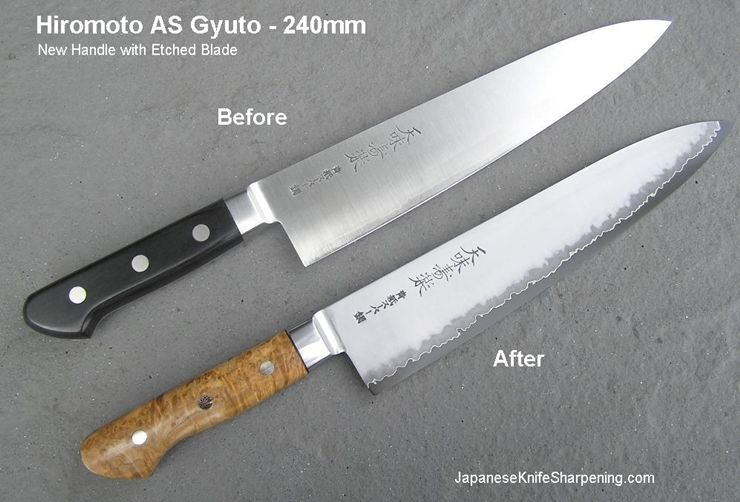

2. Performance Package ($172 Value) = Blade Thinned & Etched for Appearance, Spine/Choil Rounded, Edge Sharpened

Example

3. Rehandle Plus Performance Package ($377 Value) = Custom Rehandle plus Performance Package

Examples

Details:

Blade Thinning the knife to the max makes it an even better performer than what it is when new. This service really shows the user what a knife is capable of being.

Blade etching is a chemical process that enhances the appearance of the blade by offering contrast between the high carbon core steel and the mild stainless steel cladding.

*Please note that each and every knife will yield a different result (appearance) from this process and that we cannot predict the outcome nor accept requests for a specific look. The knife will reveal whatever look was forged into it at the time it was made. Yes the thinning process does expose more core steel then the knife shows when stock, however, the look is not affected beyond that. Still, its worth noting that the 240mm & 270mm gyutos often show the wildest patterns.

Wood choice for handle scales will be our pick from our stock of fully stabilized woods. Please note at the time of purchase if you would prefer a light (natural) or darker type of wood, plain or more crazier looking, or even a color (dyed wood) might be possible. We want you to have a knife that is customized to your specs as much as possible yet its impossible to supply each customer a specific wood at a reasonable cost, even so, well try our best to accommodate where we can.

Examples

Handle pins will be either nickel silver or copper. Mosaic pins are available for an additional charge of $12 per knife.

Spine/Choil options are smoothing or rounding. For smoothing we simply remove the sharp edges commonly found on the spine/choil of Japanese knives. For rounding we re-shape the spine/choil into a comfortable smooth and polished surface.

DONATION:

For each knife sold a $2 donation will be made to The National Breast Cancer Foundation in the name of Sue Moore

For each knife sold a $2 donation will be made to The National Breast Cancer Foundation in the name of Sue Moore

Knife Styles & Sizes Available/Pricing:

The prices shown below represent a savings from our regular service pricing.

190mm Santoku

1. Sharpening Pkg. - $134

2. Performance Pkg. - $219

3. Handle + Perf Pkg. - $399

210mm Gyuto

1. Sharpening Pkg. - $155

2. Performance Pkg. - $235

3. Handle + Perf Pkg. - $415

240mm Gyuto

1. Sharpening Pkg. - $181

2. Performance Pkg. - $252

3. Handle + Perf Pkg. - $432

270mm Gyuto

1. Sharpening Pkg. - $203

2. Performance Pkg. - $269

3. Handle + Perf Pkg. - $449

Shipping:

(Flat Rate for up to 2 knives)

CONUS - $15

International - $35

*Insurance not included

Delivery Time Estimate:

Pkg #2 & #3 = 8-12 weeks (for the first 10 orders), all others to follow.

Pkg. #1 = 4-6 weeks

*If you order knives from different packages then expect the longest delivery time for all knives as they will all be delivered at the same time.

**Please understand that this is custom work being performed that requires a lot of time to complete. We promise to deliver as soon as possible though, we like happy customers.

To Place an Order:

Please PM me with your order including your email address, your location, & handle (wood) requests. Ill follow by sending you a Paypal email invoice.

Thanks!

Dave

Hiromoto Tenmi-Jyuraku Aogami Super Steel (AS) Series

Santoku - 190mm available

Gyuto - 210mm, 240mm & 270mm available

Knife Features:

Core Steel Type - Hitachi Aogami Super Steel - 1.40-1.50 Carbon, 0.30-0.50 Chromium, 2.00-2.50 Tungsten

Cladding Steel Type - 420J1 Stainless

Stock Handle Black Staminawood

Package Options:

1. Sharpening Package ($35 Value) = Edge Sharpened, Spine/Choil Smoothed

Example - See above stock photos

2. Performance Package ($172 Value) = Blade Thinned & Etched for Appearance, Spine/Choil Rounded, Edge Sharpened

Example

3. Rehandle Plus Performance Package ($377 Value) = Custom Rehandle plus Performance Package

Examples

Details:

Blade Thinning the knife to the max makes it an even better performer than what it is when new. This service really shows the user what a knife is capable of being.

Blade etching is a chemical process that enhances the appearance of the blade by offering contrast between the high carbon core steel and the mild stainless steel cladding.

*Please note that each and every knife will yield a different result (appearance) from this process and that we cannot predict the outcome nor accept requests for a specific look. The knife will reveal whatever look was forged into it at the time it was made. Yes the thinning process does expose more core steel then the knife shows when stock, however, the look is not affected beyond that. Still, its worth noting that the 240mm & 270mm gyutos often show the wildest patterns.

Wood choice for handle scales will be our pick from our stock of fully stabilized woods. Please note at the time of purchase if you would prefer a light (natural) or darker type of wood, plain or more crazier looking, or even a color (dyed wood) might be possible. We want you to have a knife that is customized to your specs as much as possible yet its impossible to supply each customer a specific wood at a reasonable cost, even so, well try our best to accommodate where we can.

Examples

Handle pins will be either nickel silver or copper. Mosaic pins are available for an additional charge of $12 per knife.

Spine/Choil options are smoothing or rounding. For smoothing we simply remove the sharp edges commonly found on the spine/choil of Japanese knives. For rounding we re-shape the spine/choil into a comfortable smooth and polished surface.

DONATION:

Knife Styles & Sizes Available/Pricing:

The prices shown below represent a savings from our regular service pricing.

190mm Santoku

1. Sharpening Pkg. - $134

2. Performance Pkg. - $219

3. Handle + Perf Pkg. - $399

210mm Gyuto

1. Sharpening Pkg. - $155

2. Performance Pkg. - $235

3. Handle + Perf Pkg. - $415

240mm Gyuto

1. Sharpening Pkg. - $181

2. Performance Pkg. - $252

3. Handle + Perf Pkg. - $432

270mm Gyuto

1. Sharpening Pkg. - $203

2. Performance Pkg. - $269

3. Handle + Perf Pkg. - $449

Shipping:

(Flat Rate for up to 2 knives)

CONUS - $15

International - $35

*Insurance not included

Delivery Time Estimate:

Pkg #2 & #3 = 8-12 weeks (for the first 10 orders), all others to follow.

Pkg. #1 = 4-6 weeks

*If you order knives from different packages then expect the longest delivery time for all knives as they will all be delivered at the same time.

**Please understand that this is custom work being performed that requires a lot of time to complete. We promise to deliver as soon as possible though, we like happy customers.

To Place an Order:

Please PM me with your order including your email address, your location, & handle (wood) requests. Ill follow by sending you a Paypal email invoice.

Thanks!

Dave

Last edited by a moderator: