- Thread starter

- #61

Don't have any in stock at the moment. Please send me a PM/email if interested.Would you happen to be selling brush handles?

Perhaps with a minor change?

Don't have any in stock at the moment. Please send me a PM/email if interested.Would you happen to be selling brush handles?

Perhaps with a minor change?

Don't have any in stock at the moment. Please send me a PM/email if interested.

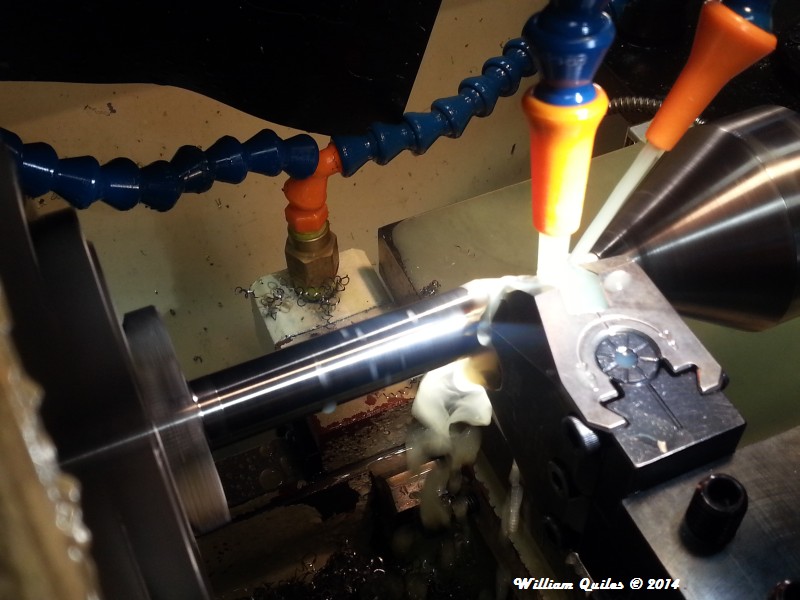

I am considering a different style, more like the Ti DE handles I am making.So you are doing shaving brushes again ?

. I have a good selection of insert tool holders and inserts however. I really like your work if I haven't said so already.

. I have a good selection of insert tool holders and inserts however. I really like your work if I haven't said so already.

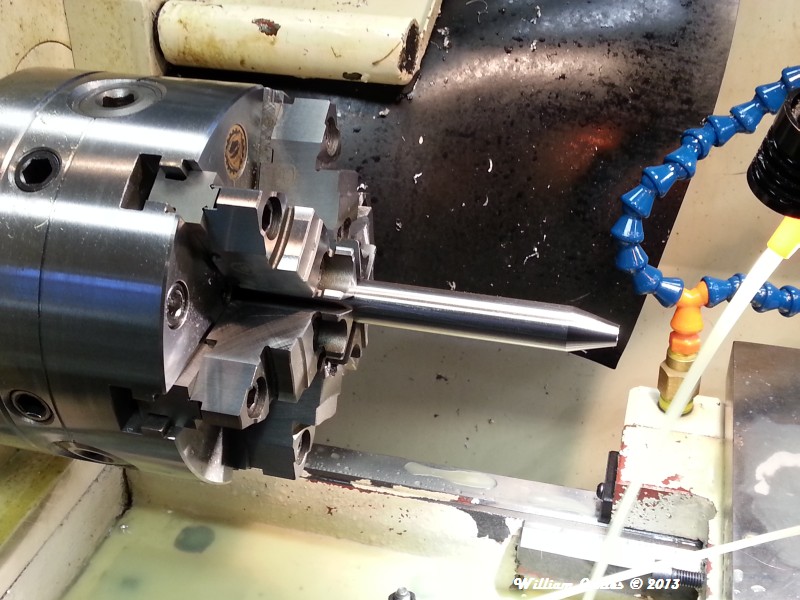

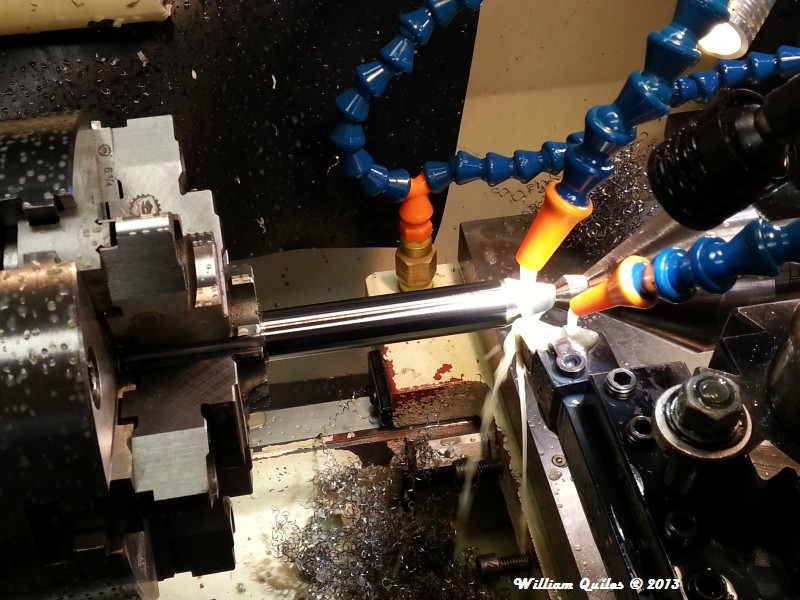

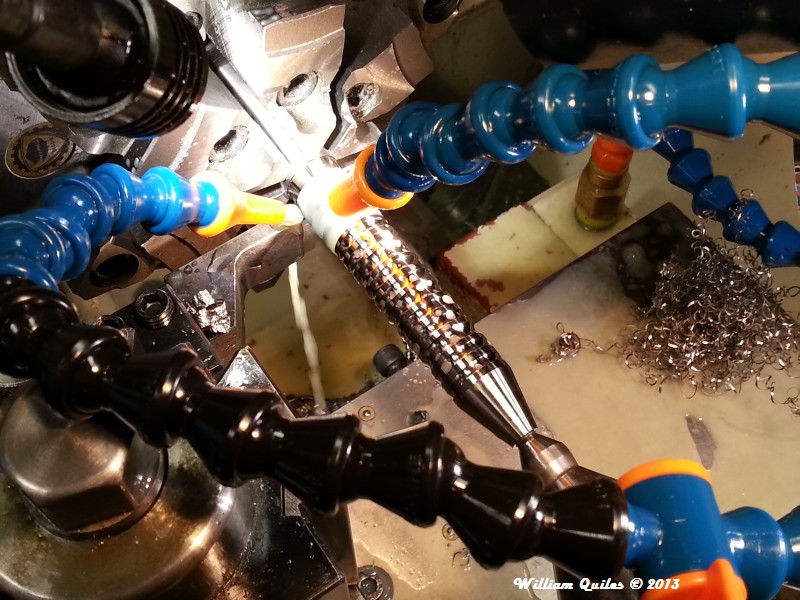

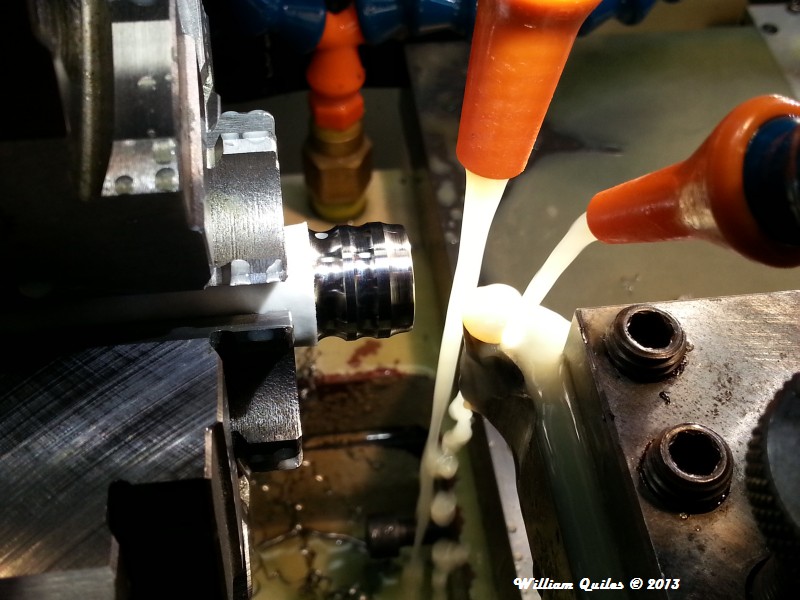

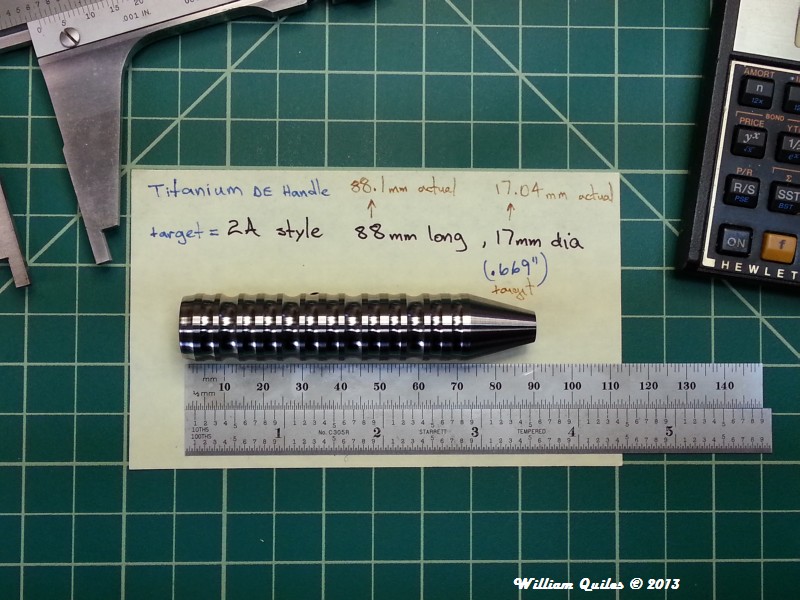

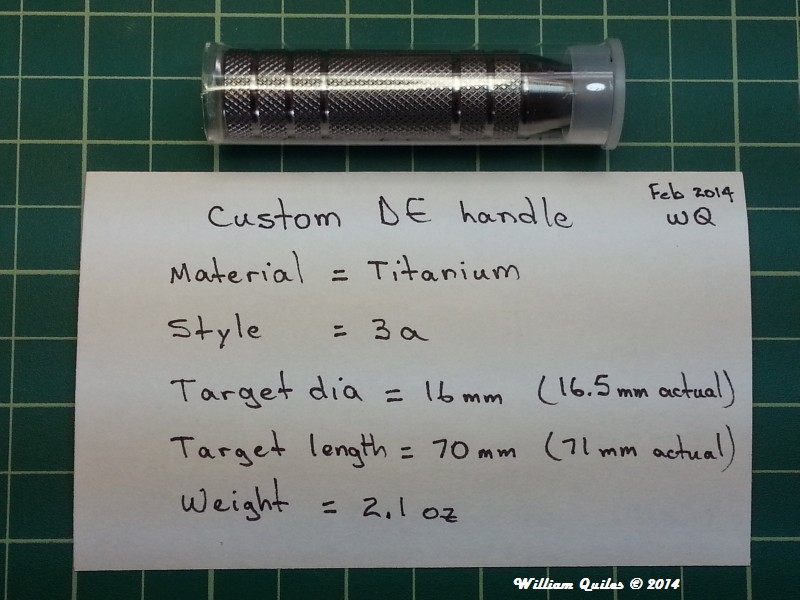

Latest custom Ti DE handle, for one of my international customers.