- Thread starter

- #41

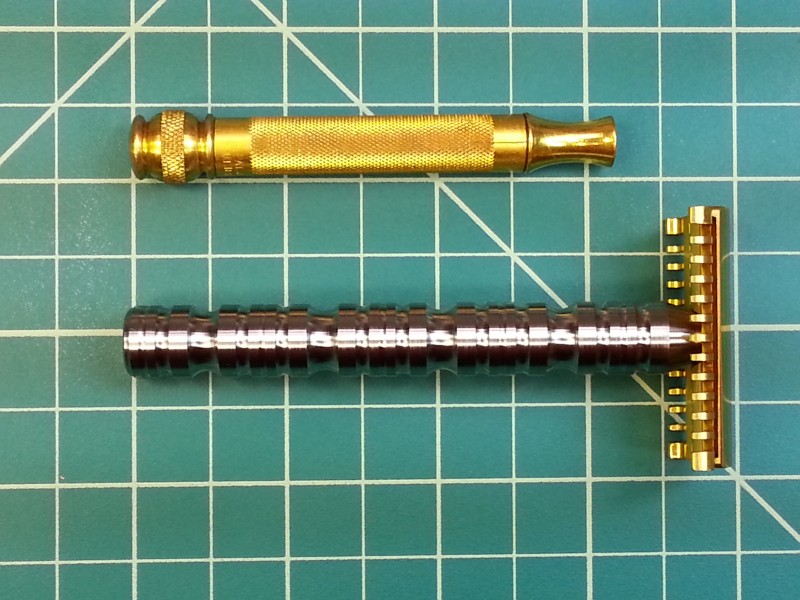

A forum member asked me about making a fat DE handle out of brass, so I got some brass to try it out. Here is the new brass piece next to the Titanium rod:

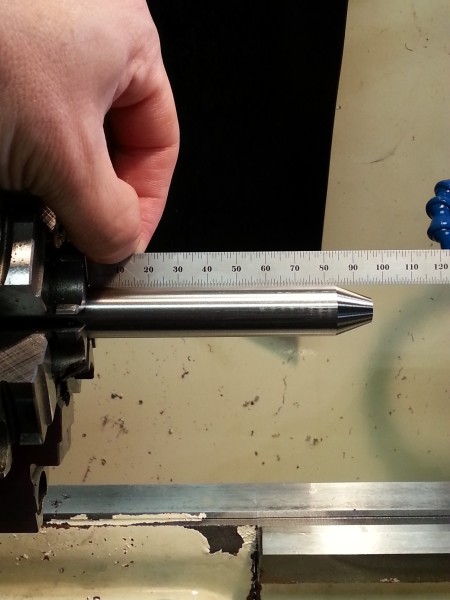

Face off:

Spot drill:

Drill and tap (M5x0.8):

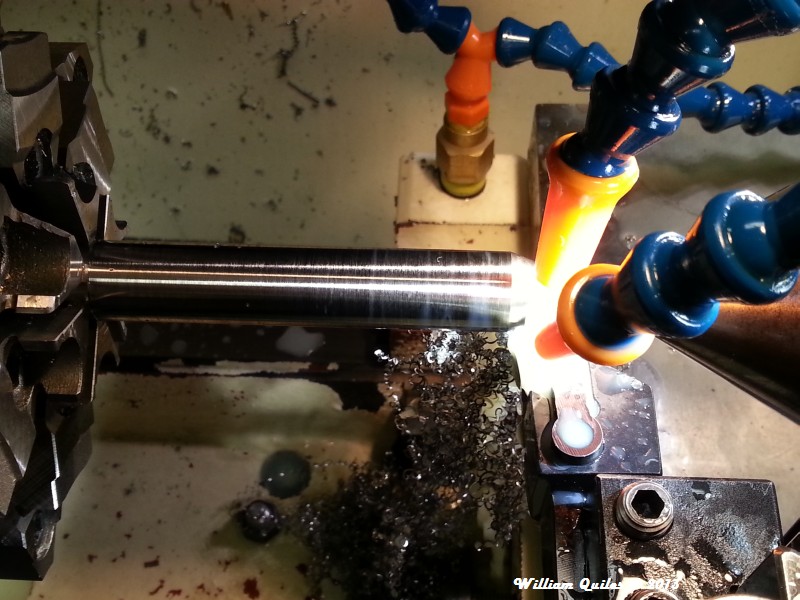

Clean and make the OD even and smooth, in preparation for knurling:

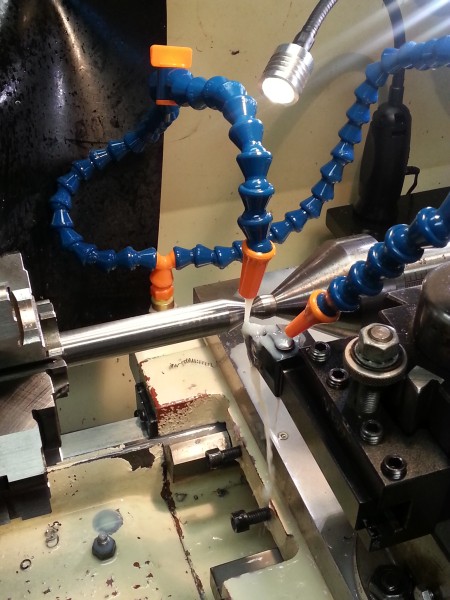

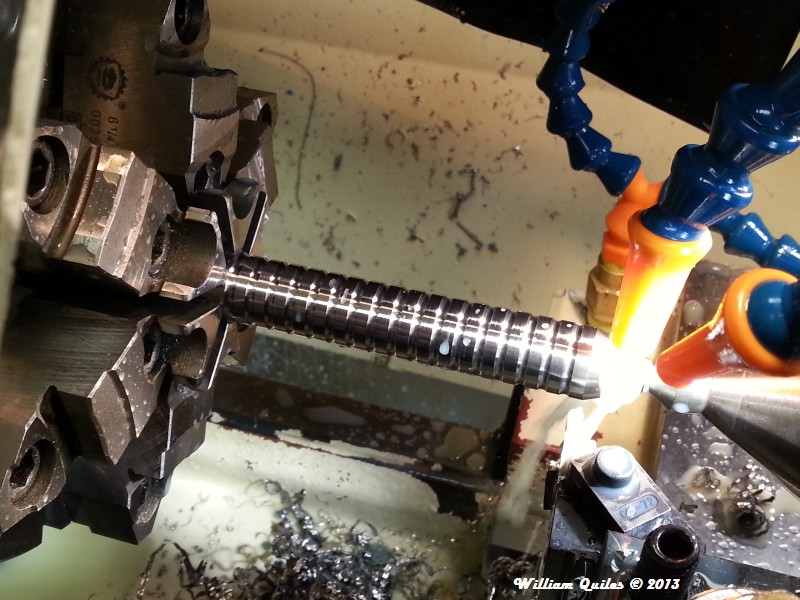

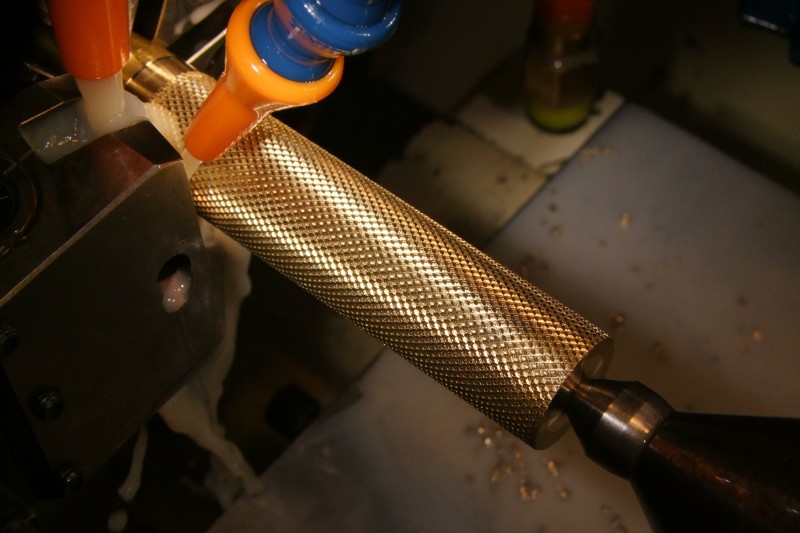

Knurl the piece (most time consuming):

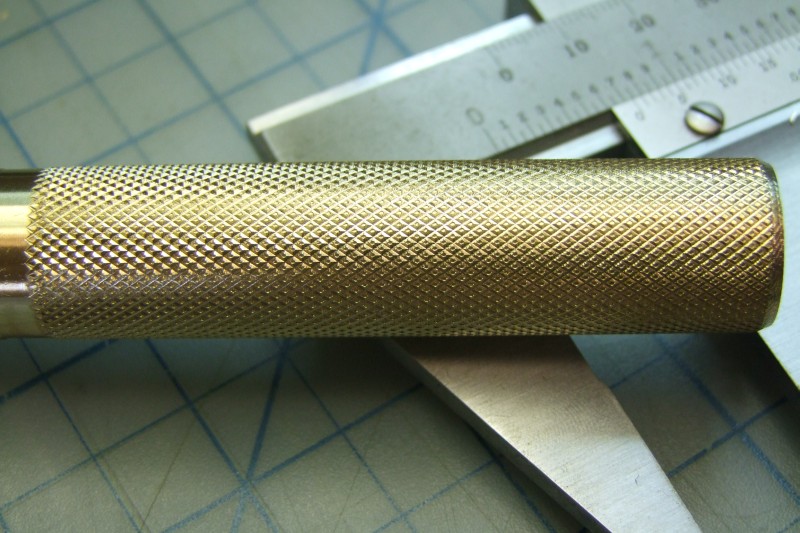

Knurling complete:

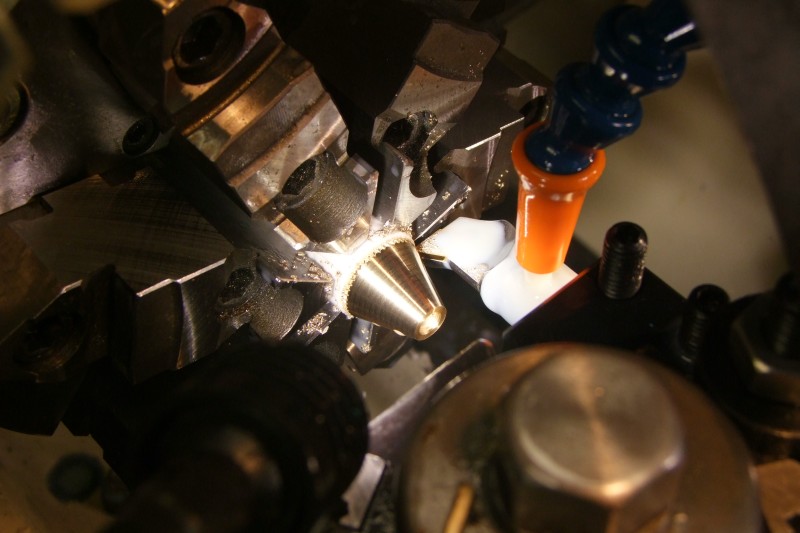

Cut the cone:

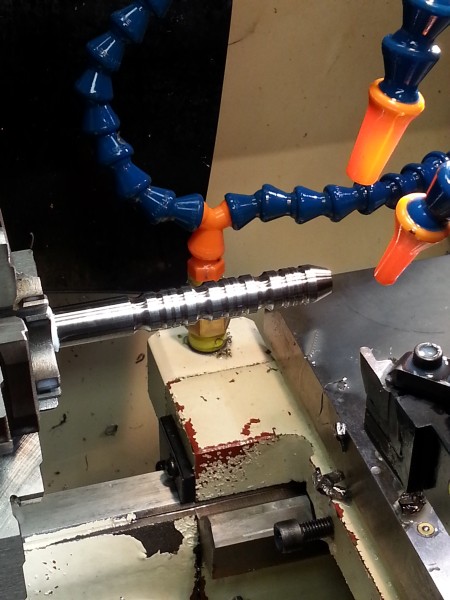

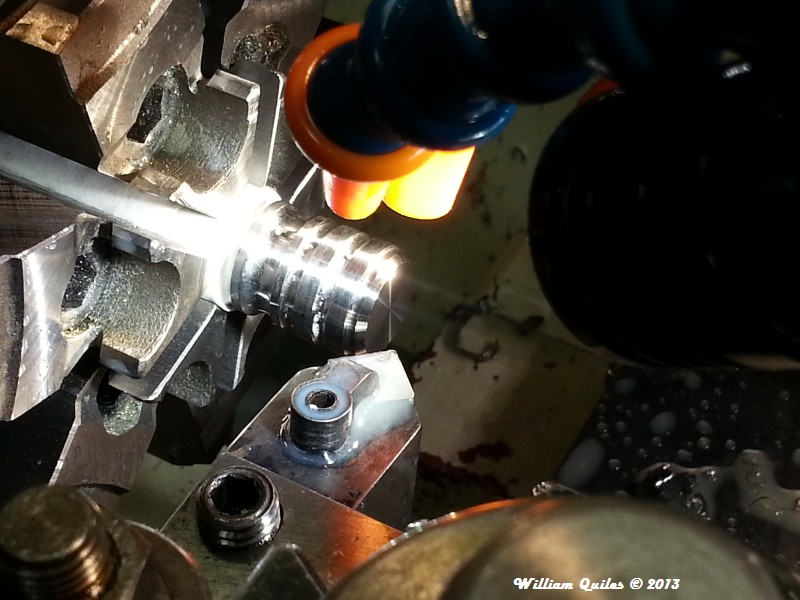

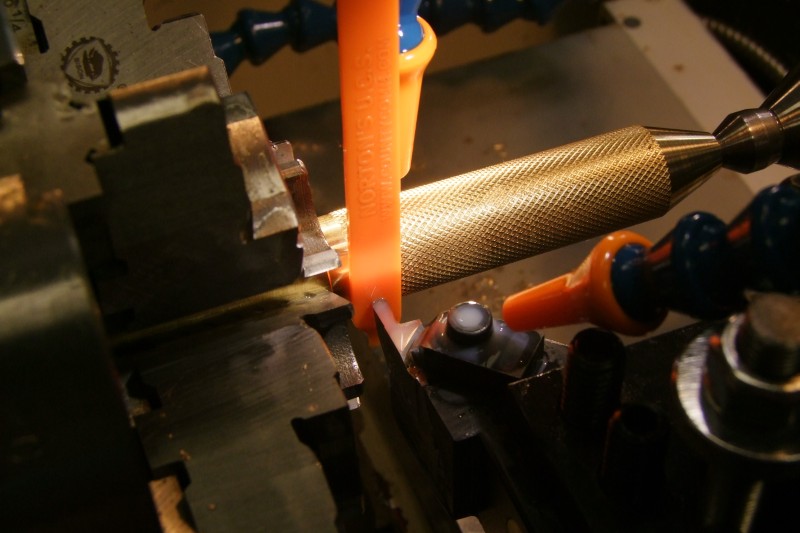

Check tool alignment, and cut grooves:

Now trim the handle to length (about 3") and face base:

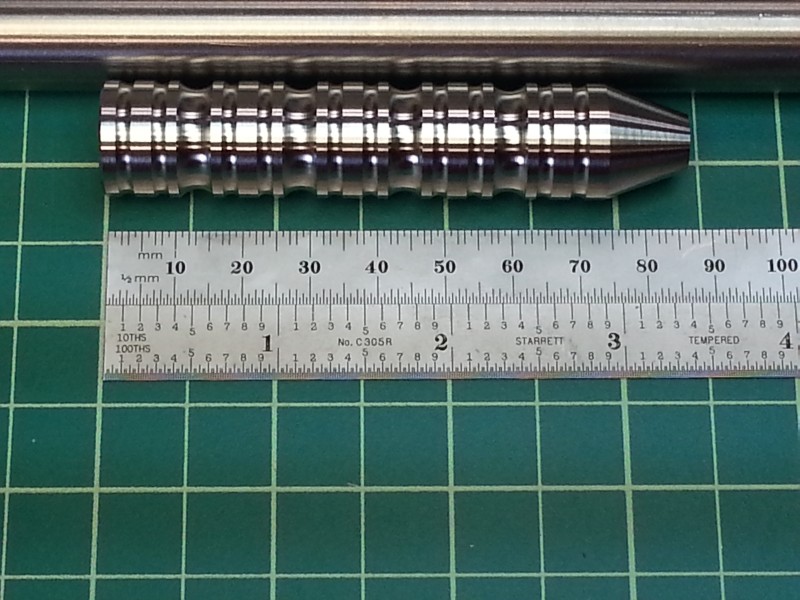

Work complete - here is a close-up:

On an EJ89 head:

Face off:

Spot drill:

Drill and tap (M5x0.8):

Clean and make the OD even and smooth, in preparation for knurling:

Knurl the piece (most time consuming):

Knurling complete:

Cut the cone:

Check tool alignment, and cut grooves:

Now trim the handle to length (about 3") and face base:

Work complete - here is a close-up:

On an EJ89 head: