I was just thinking about that today. I've got a small piece about 2.5" x 4" almost lapped to where I can put a blade on it to see if that formation is worth pursuing. If it is I will try getting deeper into the seem where the rock is less weathered.Can you stabilize a larger piece by bonding to a piece of tile?

Phil

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making a hone

- Thread starter xMackx

- Start date

2.5 x 4 inch is a pretty nice size honestly. No *need* for bigger, but bigger is quicker to use in reality. More removed material per stroke.

Phil

Phil

I prefer bigger for honing, but small is nice for lapping.

Looks interesting but you won't know until you try it. I might try lapping the side and trying a narrow chisel or knife on the separate layers to see what's what.

That should be fun to lap.oh i should add thats a side profile each layer creates a 6" wide strip on the top

When I'm testing a new rock, I have started trying to lap the smallest piece that I think I can hone on. Then I can determine if it's worth lapping a larger piece. If the rock is not worth it, I saved a lot of lapping time. Making your own hones gives you a new perspective on size and it starts making sense why so few naturals are large. Lapping difficulty increases faster than linear with area.

That's the truth! I'll add that after you try lapping a bunch of naturals and get a bunch of slow 3K-8K stones, you start to appreciate the fast and/or fine stones...Making your own hones gives you a new perspective on size and it starts making sense why so few naturals are large. Lapping difficulty increases faster than linear with area.

Something that big would start on the sidewalk for lapping! Concrete can be a pretty good lap material.

Phil

Phil

Thinking about the fact that some of the Apache Strada stones are sleepers has me revisiting some of the found stones that I had given up on. Maybe I just picked up a bad piece! Alex has stated that only about 1% of the JNats coming out of the mines were razor quality. His recent videos showing piles of stones around the mines and his comment about them sitting out for too long to still be of value doesn't bode well for us rock hounds either.

Tagging this...but still on page 19. I live in Arizona, and as has been said...we have about ten million kinds of potential finisher quality stuff just laying around to be picked up.

I also have a C12k, another cool Guangxi hone, an Apache Strata, and Apache Red...and some cool local stuff I've been working on that I'm looking forward to discussing...if I ever get done reading lol.

I also have a C12k, another cool Guangxi hone, an Apache Strata, and Apache Red...and some cool local stuff I've been working on that I'm looking forward to discussing...if I ever get done reading lol.

Welcome to the thread Cris. I look forward to hear about your finds.

Well! This has been a really long, and interesting thread lol!!

My own experience with self made stones is very minimal, but in my short time dealing with razors I've had some extensive experience with four of the natural hones being sold online. The first is a Guangxi '2k'...which seems to cut anywhere from 1k to 6-8k (I've handled six of them with similar results). I actually use this stone with 1k and 6k King synthetic slurry for a really interesting 'Jnat' effect on the edge bevel. The second is the Guangxi 12k, or C12k, or PHIG, or whatever they're being called now. The final two are the Apache Red and Apache Strata from naturalhones.com. The stone I made myself seems to be a form of quartzite with red/yellow coloration and black lines. Surprisingly this stone cuts quite well for what it is...though I think that's more a factor of surface preparation. I would say the finish is roughly 8k, off of a 600 grit diamond plate surface.

Here's a few pictures of the various stones:

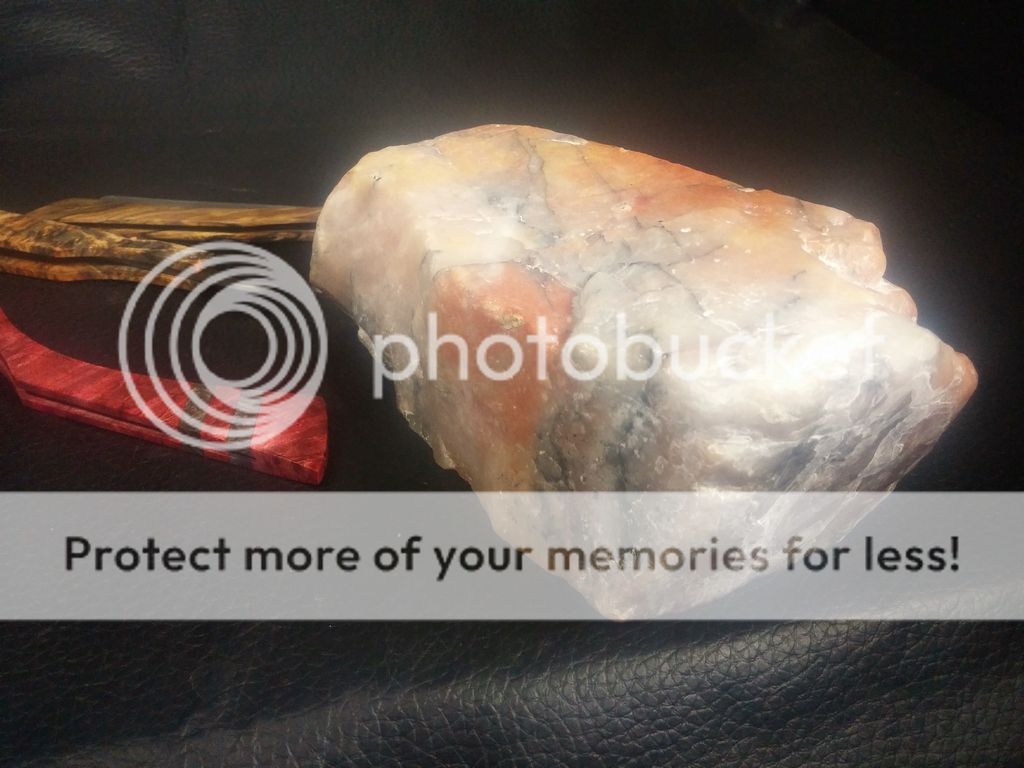

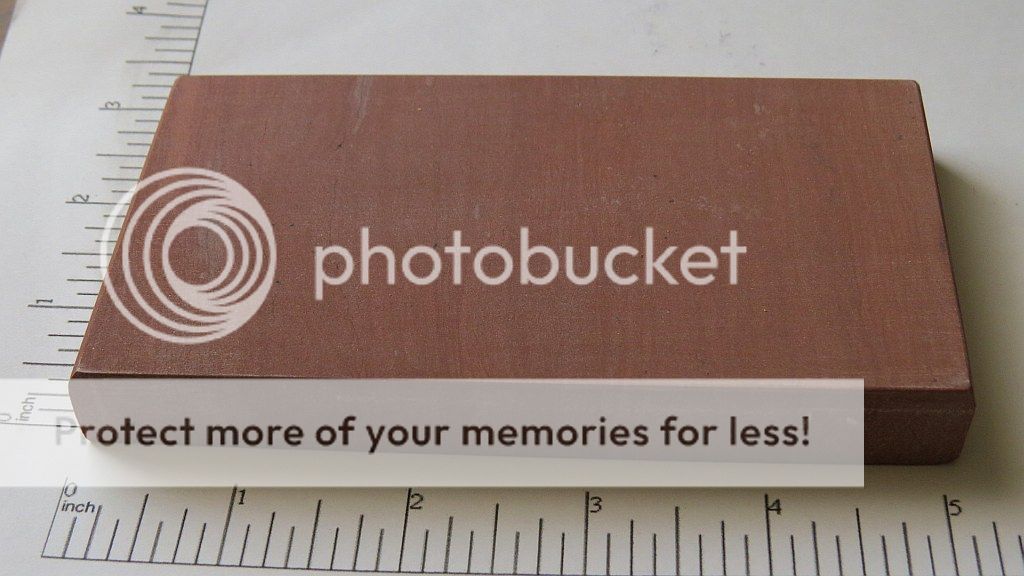

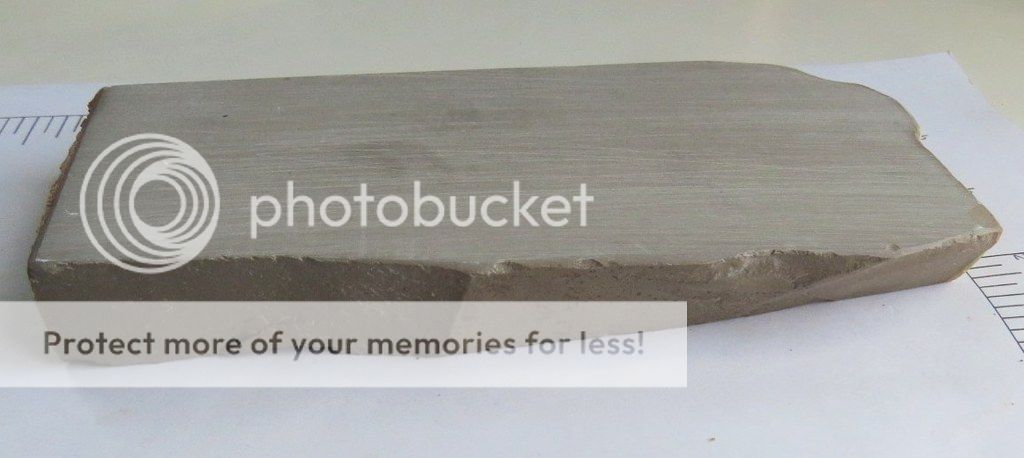

This is the natural state of the stone I am working on. It appears to be some type of quartzite. The breaks have a glassy/waxy appearance, and it was naturally polished in a roughly rectangular shape. Dimensions are 5.5"x3"x2". If it continues to show promise I'll roughly flatten one side, then pick up a tile saw and slab it out.

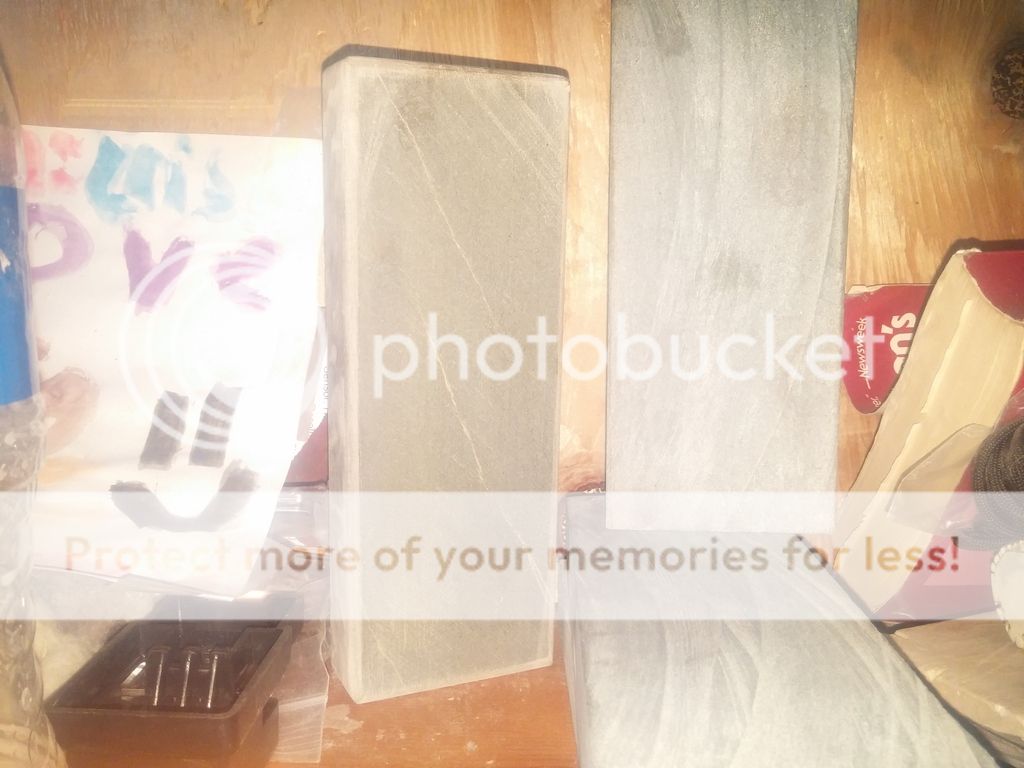

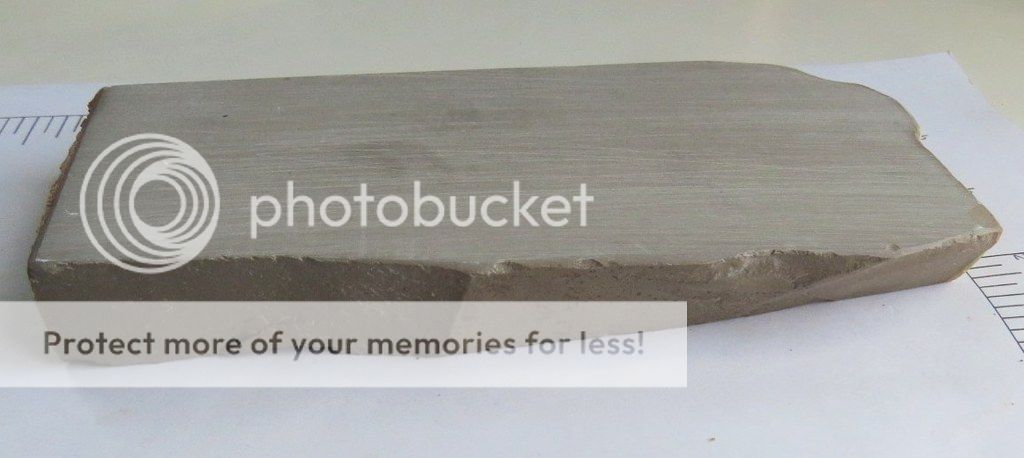

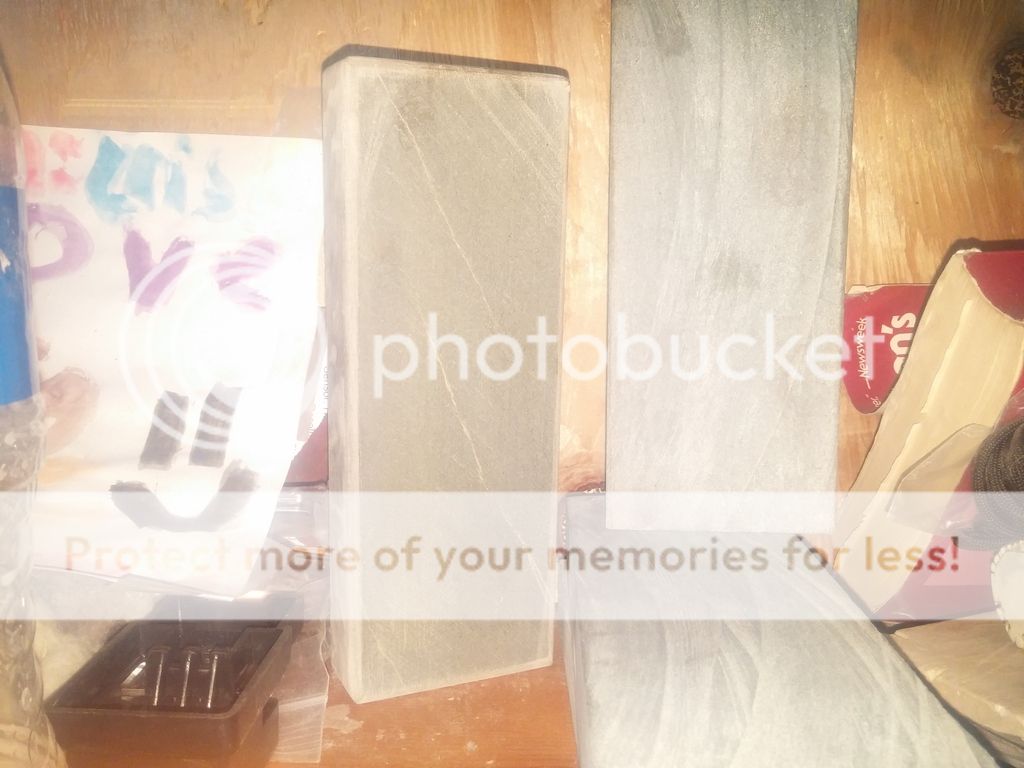

This is the cut and lapped side. To those of you doing all of this work by hand, I salute you. I used my 3hp water cooled 2x72 belt grinder on it with a fresh Norton Blaze 40 grit belt, and got almost nowhere. I then switched to an angle grinder with a metal cutting disc...just touching it up with the belt grinder to verify the high spots, and things progressed a bit more quickly. It still took 2hrs with a 200 grit diamond plate to get it to this level. It still needs some work (I want it completely flat on the top!!), but its flat enough to run a razor on and test. I took it up to a 600 grit polish, and it cuts surprisingly well. 20 or so laps will begin generating a barely visible swarf on a 63HRC W2 tool steel razor. The scratch pattern appears to be a roughly 8k grit, going off of what the pattern looks like off of a 6k King with no slurry.

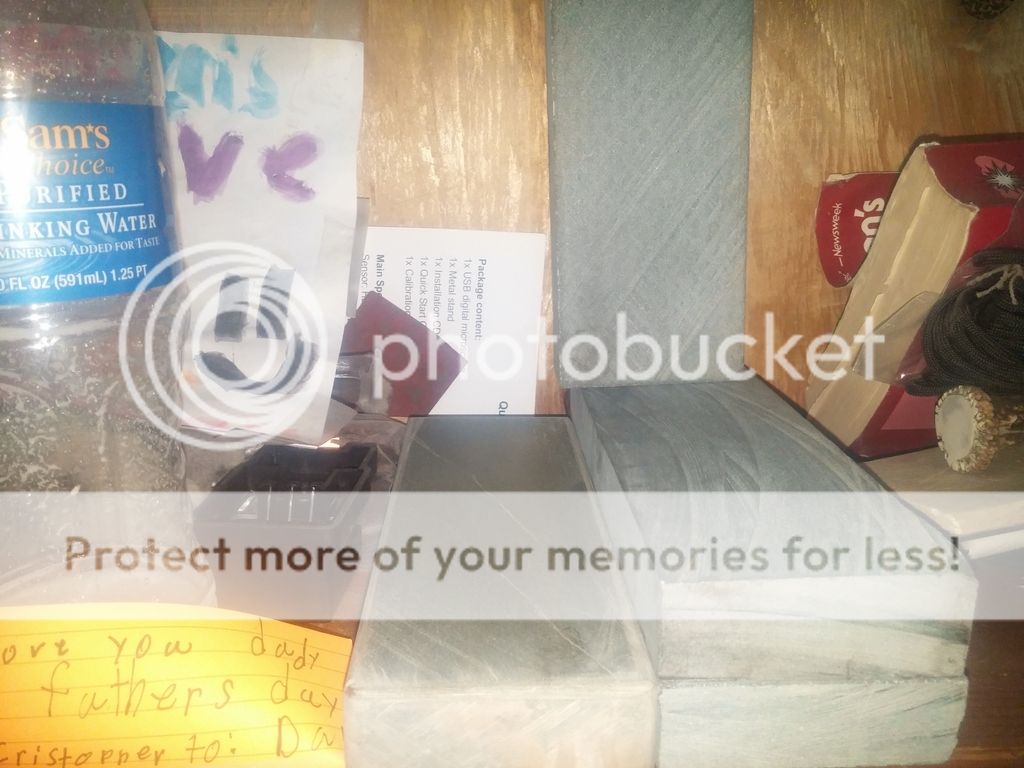

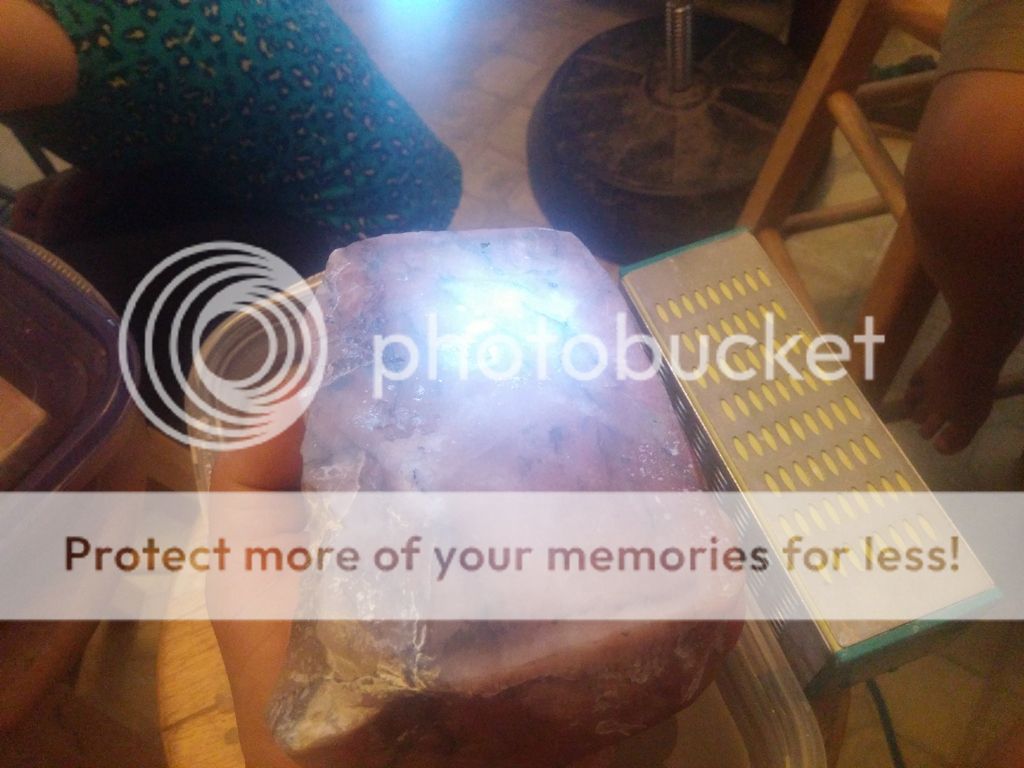

The main inclusion left on the surface of the stone. Right now this is going to take more effort than I'm willing to invest to remove lol...but I'll get to it eventually. These pits were caused by the heat produced with the grinders. The surface would be juuuust about completely smooth, and then I'd leave it against the belt a bit too long and suddenly hear/feel a click/pop. Sure enough, there would be a new divot. I eventually gave up on straightening it out with the belt for this reason, and switched solely to hand lapping.

The success with this stone prompted me to order a piece of fortification agate (already lapped, thank GOD lol), as well as another piece of quartzite...this time green. The green is supposed to have a high chromium/mica content, which might improve the cutting ability even further:

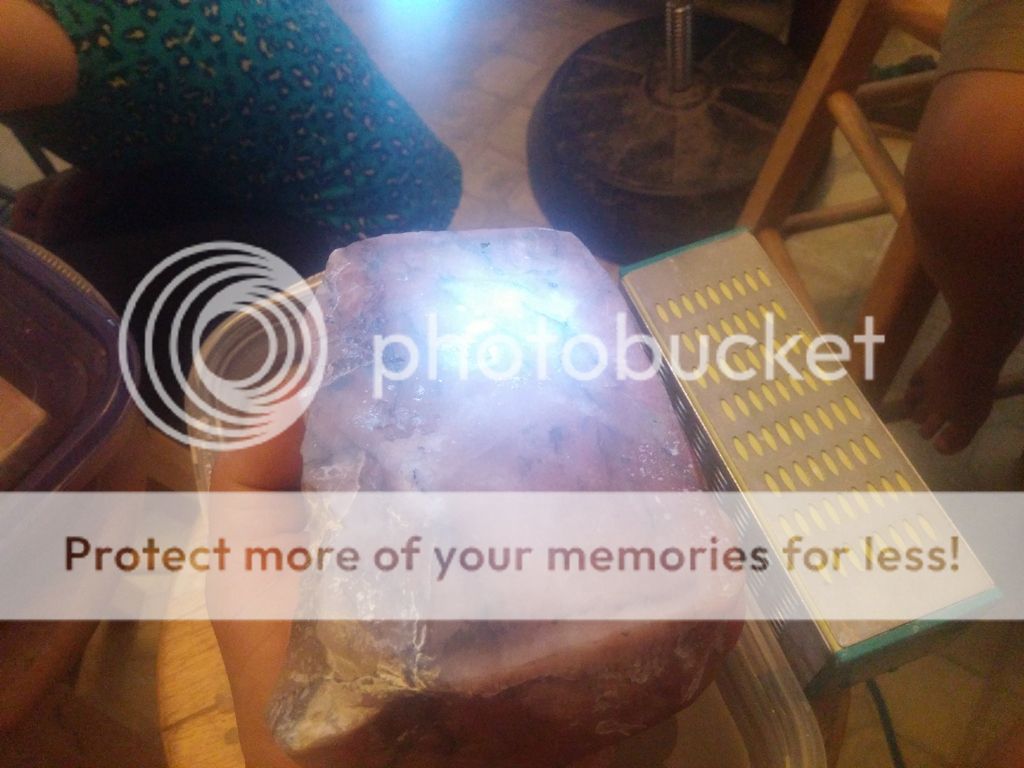

Fortification agate. I picked up a slab that's 5.5"x3.5"x3/8" thick for about $20 shipped. Even if it doesn't work for a hone, its quite beautiful so I figure it's worth the money .

.

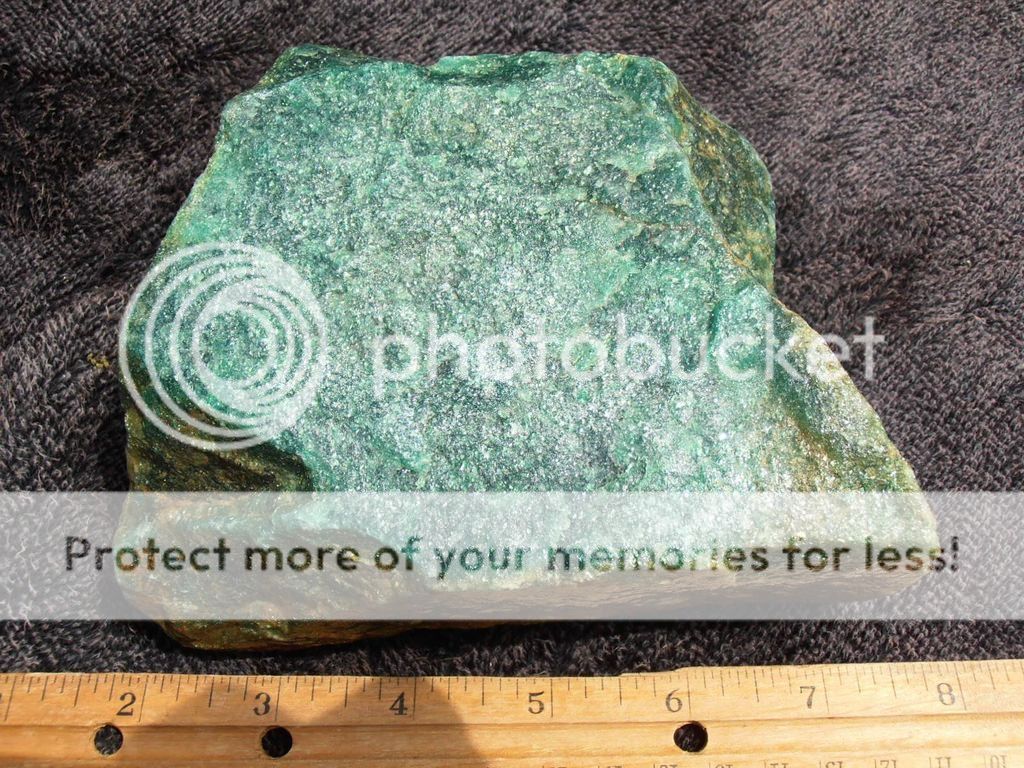

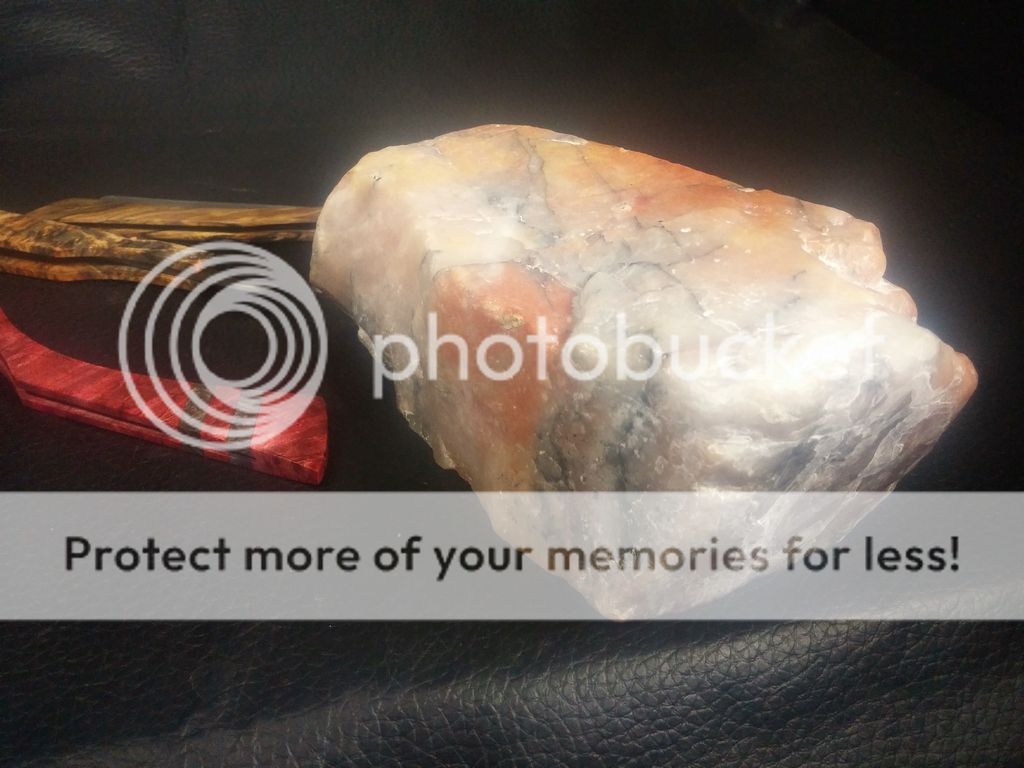

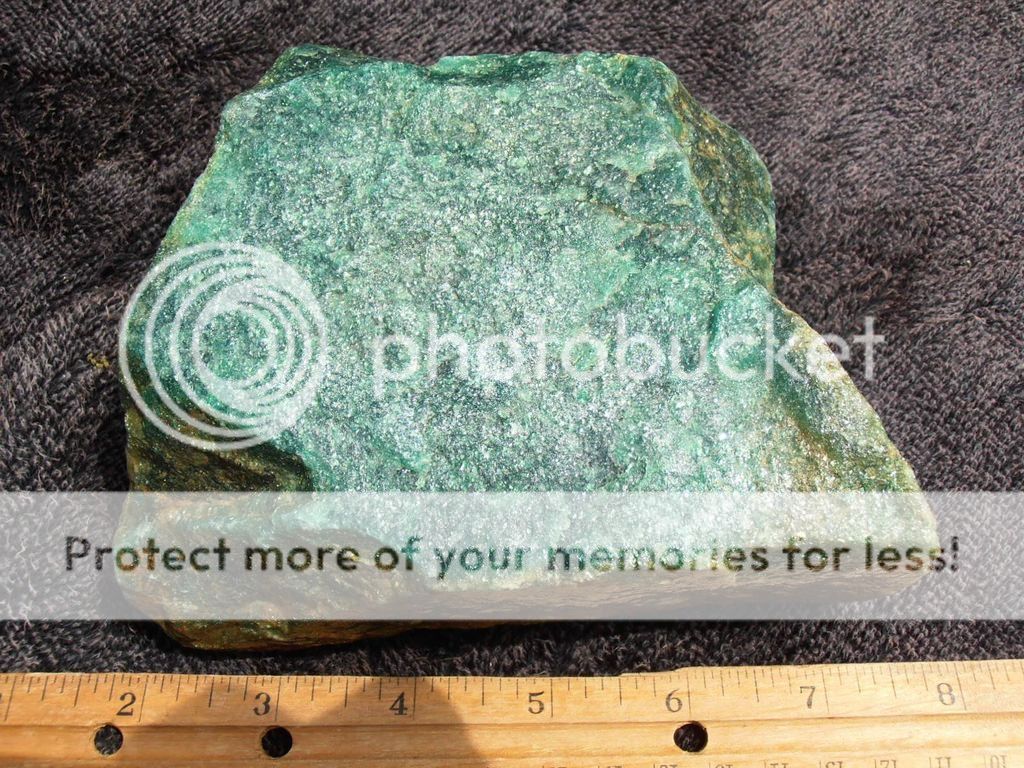

This is the green quartzite. Dimensions are around 6"x4"x2". If this makes a successful hone I'll slab it out as well.

My other natural stones were all bought or traded for...but I have pictures of them as well.

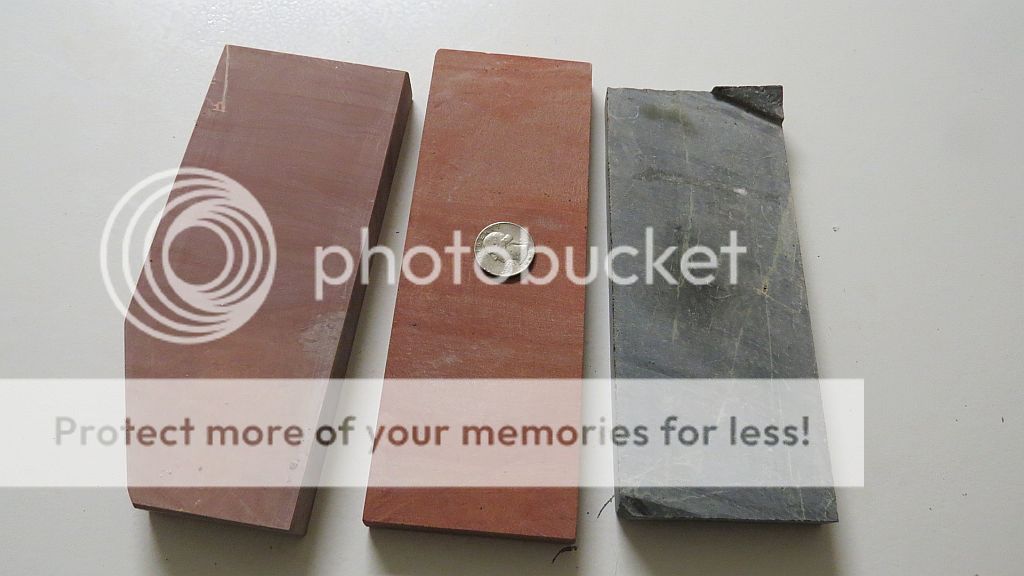

On the left is the Guangxi '2k' and on the right the 12k. The 2k is an AMAZING finisher for kitchen knives, as with pressure I can cut in a fresh bevel on a 65HRC tool steel knife that has never been sharpened (literally, flat on the edge), then...with nothing more than reducing pressure...I can take the edge to a nice and toothy 6-8k level of refinement. I've used it on razors as well...and have shaved directly off of it...and while it wasn't the most enjoyable shave I've had, it wasn't what I'd call horrible or extremely unpleasant either. If I could only have one stone to do everything with...this would be it. The material seems to be some sort of slate with a very high quartz content. All six stones I've had in my hands so far have been very similar in composition and effectiveness. The C12k also appears to be of slate origin, though much more fine...and does not have the quartz content. The feel and effectiveness of those have been well documented on this site however, so I won't go into much more detail than that. Both of those stones come from the Guangxi province, per my distributor.

A few more pictures of the 2k...as they come to me (on the right), and after I've roughed them out (on the left). They get a little higher level of polish before use of course.

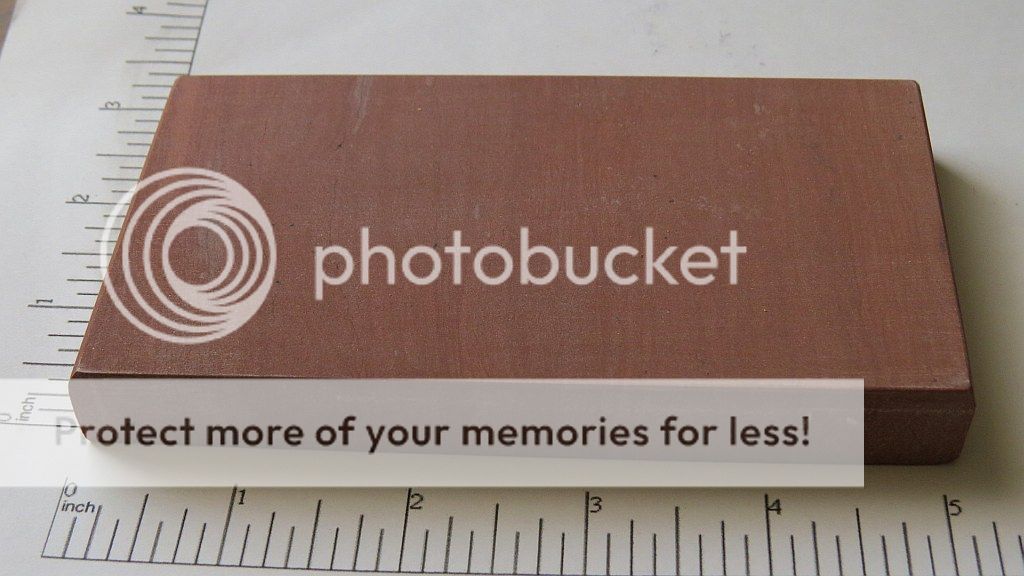

Here we have the Apache Red. this stone was rated by Terry at 8-10k, but honestly...mine seems to act substantially finer. This is probably due to the level of polish I put on the surface. I have worked the stone to a nearly mirror level of finish:

As you can see the surface is quite reflective. I would put this hone at an easy 10-12k now in comparison with the others (we all know grit is subjective of course...but comparing the resultant edges at 500x...this is what I see). The surface was achieved by simply honing first, then later by honing with .5 micron diamond spray/slurry (in water), then eventually by lapping it against my Apache Strata with the .5 micron diamond spray as the lubricant.

Here's my Apache Strata. At first this stone seemed...eh. I don't know how much of that was a function of my newness to honing razors, my complete lack of experience straight razor shaving, or just the lack of refinement of the stone's surface. With time, this finisher has really become top notch though. It cuts a bit more quickly than the quartzite hone I made, with a much higher level of refinement I can HHT (3 to 4) off of this stone and the Red now...something I have as yet been unable to achieve with the others.

Here's my Apache Strata. At first this stone seemed...eh. I don't know how much of that was a function of my newness to honing razors, my complete lack of experience straight razor shaving, or just the lack of refinement of the stone's surface. With time, this finisher has really become top notch though. It cuts a bit more quickly than the quartzite hone I made, with a much higher level of refinement I can HHT (3 to 4) off of this stone and the Red now...something I have as yet been unable to achieve with the others.

The level of reflectiveness of the Strata. The surface preparation was the same as the Red. Razor honing, then razor honing on .5 micron diamond slurry, then eventually lapping against the Red with .5 micron slurry. This finisher is excellent, and for every step up my skills improve, it seems to take two steps of its own.

For comparison, here's the surface finish of the quartzite hone:

Anyhow...there you have it...my entire natural hone selection. I'm looking forward to getting out to the desert (I'm in Phoenix) this fall to look for other promising hones...though I have no idea where to look yet. If you guys have researched any areas of interest, please clue me in. I know Nobody was quite active in these areas...but it appears he hasn't been online in quite awhile. If I can find anything interesting, and I pick up a slab saw...I'll be more than happy to share them out to you all...particularly if I can get the information on where to look from this thread.

My own experience with self made stones is very minimal, but in my short time dealing with razors I've had some extensive experience with four of the natural hones being sold online. The first is a Guangxi '2k'...which seems to cut anywhere from 1k to 6-8k (I've handled six of them with similar results). I actually use this stone with 1k and 6k King synthetic slurry for a really interesting 'Jnat' effect on the edge bevel. The second is the Guangxi 12k, or C12k, or PHIG, or whatever they're being called now. The final two are the Apache Red and Apache Strata from naturalhones.com. The stone I made myself seems to be a form of quartzite with red/yellow coloration and black lines. Surprisingly this stone cuts quite well for what it is...though I think that's more a factor of surface preparation. I would say the finish is roughly 8k, off of a 600 grit diamond plate surface.

Here's a few pictures of the various stones:

This is the natural state of the stone I am working on. It appears to be some type of quartzite. The breaks have a glassy/waxy appearance, and it was naturally polished in a roughly rectangular shape. Dimensions are 5.5"x3"x2". If it continues to show promise I'll roughly flatten one side, then pick up a tile saw and slab it out.

This is the cut and lapped side. To those of you doing all of this work by hand, I salute you. I used my 3hp water cooled 2x72 belt grinder on it with a fresh Norton Blaze 40 grit belt, and got almost nowhere. I then switched to an angle grinder with a metal cutting disc...just touching it up with the belt grinder to verify the high spots, and things progressed a bit more quickly. It still took 2hrs with a 200 grit diamond plate to get it to this level. It still needs some work (I want it completely flat on the top!!), but its flat enough to run a razor on and test. I took it up to a 600 grit polish, and it cuts surprisingly well. 20 or so laps will begin generating a barely visible swarf on a 63HRC W2 tool steel razor. The scratch pattern appears to be a roughly 8k grit, going off of what the pattern looks like off of a 6k King with no slurry.

The main inclusion left on the surface of the stone. Right now this is going to take more effort than I'm willing to invest to remove lol...but I'll get to it eventually. These pits were caused by the heat produced with the grinders. The surface would be juuuust about completely smooth, and then I'd leave it against the belt a bit too long and suddenly hear/feel a click/pop. Sure enough, there would be a new divot. I eventually gave up on straightening it out with the belt for this reason, and switched solely to hand lapping.

The success with this stone prompted me to order a piece of fortification agate (already lapped, thank GOD lol), as well as another piece of quartzite...this time green. The green is supposed to have a high chromium/mica content, which might improve the cutting ability even further:

Fortification agate. I picked up a slab that's 5.5"x3.5"x3/8" thick for about $20 shipped. Even if it doesn't work for a hone, its quite beautiful so I figure it's worth the money

This is the green quartzite. Dimensions are around 6"x4"x2". If this makes a successful hone I'll slab it out as well.

My other natural stones were all bought or traded for...but I have pictures of them as well.

On the left is the Guangxi '2k' and on the right the 12k. The 2k is an AMAZING finisher for kitchen knives, as with pressure I can cut in a fresh bevel on a 65HRC tool steel knife that has never been sharpened (literally, flat on the edge), then...with nothing more than reducing pressure...I can take the edge to a nice and toothy 6-8k level of refinement. I've used it on razors as well...and have shaved directly off of it...and while it wasn't the most enjoyable shave I've had, it wasn't what I'd call horrible or extremely unpleasant either. If I could only have one stone to do everything with...this would be it. The material seems to be some sort of slate with a very high quartz content. All six stones I've had in my hands so far have been very similar in composition and effectiveness. The C12k also appears to be of slate origin, though much more fine...and does not have the quartz content. The feel and effectiveness of those have been well documented on this site however, so I won't go into much more detail than that. Both of those stones come from the Guangxi province, per my distributor.

A few more pictures of the 2k...as they come to me (on the right), and after I've roughed them out (on the left). They get a little higher level of polish before use of course.

Here we have the Apache Red. this stone was rated by Terry at 8-10k, but honestly...mine seems to act substantially finer. This is probably due to the level of polish I put on the surface. I have worked the stone to a nearly mirror level of finish:

As you can see the surface is quite reflective. I would put this hone at an easy 10-12k now in comparison with the others (we all know grit is subjective of course...but comparing the resultant edges at 500x...this is what I see). The surface was achieved by simply honing first, then later by honing with .5 micron diamond spray/slurry (in water), then eventually by lapping it against my Apache Strata with the .5 micron diamond spray as the lubricant.

The level of reflectiveness of the Strata. The surface preparation was the same as the Red. Razor honing, then razor honing on .5 micron diamond slurry, then eventually lapping against the Red with .5 micron slurry. This finisher is excellent, and for every step up my skills improve, it seems to take two steps of its own.

For comparison, here's the surface finish of the quartzite hone:

Anyhow...there you have it...my entire natural hone selection. I'm looking forward to getting out to the desert (I'm in Phoenix) this fall to look for other promising hones...though I have no idea where to look yet. If you guys have researched any areas of interest, please clue me in. I know Nobody was quite active in these areas...but it appears he hasn't been online in quite awhile. If I can find anything interesting, and I pick up a slab saw...I'll be more than happy to share them out to you all...particularly if I can get the information on where to look from this thread.

Last edited:

Just picked up three more local stones from Terry at Natural Hones. I know this thread is about finding and/or making your own...but these stones are local to me...so it'll be nice to see what it is I should be looking for. I know that my Apache Red and Strata I posted above are the best finishers I've seen. I loaned them to my friend down at Phoenix Knife House (they have a sharpening service which includes razors) for a week, and he said he hadn't seen anything like them. In doing my research, they are definitely a form of siltstone or claystone. Possibly with very fine quartz content. This kind of rock is all over the place in southern Arizona...though each individual location will probably have its own characteristics.

Here's a couple pictures of the exact stones I bought:

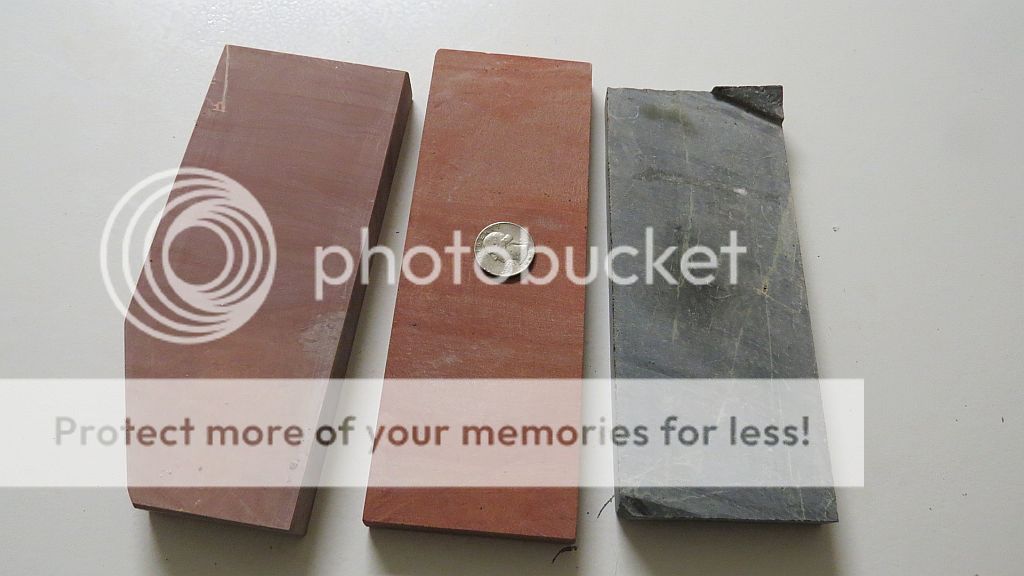

Wet and dry. He's sending them to me rough cut...I'll put my own work into polishing them. From left to right are an experimental 'dark red' or 'purple' hone that he said razor guys didn't like because it felt 'gritty'. I'll be trying it out on kitchen knives myself. In the middle is another Apache Red like the one I posted above, just bigger. The one on the right is the one that most interests me though, that I can't wait to get my paws on. It's the Apache 'Black Gila'. It supposedly cuts more quickly than the Apache Strata, and leaves a more refined edge as well. We'll be seeing here in a few days .

.

Again...the exciting thing for me is these are local stones. It's REALLY cool seeing what they're all about!

Here's a couple pictures of the exact stones I bought:

Wet and dry. He's sending them to me rough cut...I'll put my own work into polishing them. From left to right are an experimental 'dark red' or 'purple' hone that he said razor guys didn't like because it felt 'gritty'. I'll be trying it out on kitchen knives myself. In the middle is another Apache Red like the one I posted above, just bigger. The one on the right is the one that most interests me though, that I can't wait to get my paws on. It's the Apache 'Black Gila'. It supposedly cuts more quickly than the Apache Strata, and leaves a more refined edge as well. We'll be seeing here in a few days

Again...the exciting thing for me is these are local stones. It's REALLY cool seeing what they're all about!

Good stuff Cris.

For sure man! I'm super excited about it. The Gila looks like it was cut from the same piece that one of the forum members here has, and he's super thrilled with the thing.

As Nobody said (is he still around at all?), this area of the US is chocked full of volcanic and sedimentary rock. If someone took the time and effort, and got a little lucky...I bet there are some truly amazing stones in this area for honing. The Apache series of hones are stellar examples of exactly what I mean.

As Nobody said (is he still around at all?), this area of the US is chocked full of volcanic and sedimentary rock. If someone took the time and effort, and got a little lucky...I bet there are some truly amazing stones in this area for honing. The Apache series of hones are stellar examples of exactly what I mean.

Terry is slabbing up some interesting stuff for sure. I like my Gila, good stuff.

kcb5150 has been finding very slight gold particles in his, lol.

I haven't got around to doing much here in the last few weeks as far as the quartzite stuff goes...but it's definitely on my list to do.

I haven't got around to doing much here in the last few weeks as far as the quartzite stuff goes...but it's definitely on my list to do.

I found a deposit of what I would call schist that is showing some promise. I've still got a lot of lapping to do before I have a big enough area to test.

Similar threads

- Replies

- 63

- Views

- 5K

- Replies

- 3

- Views

- 781