i got a 'Hoppe Special' razor a number of years ago that I was revisiting last night and the razor has somewhat of a 'frown' rather than a 'smile'. are these still honeable with that reverse smile in the middle of the blade? the blade appears to have some hone wear on it also, but it's in good condition. i was able to shine it up pretty well, i'd like to be able to rescale it and use it..

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

razor with a 'frown'

- Thread starter ahoiberg

- Start date

Yes, a razor with a frown can be honed. To be done properly the edge would need to be straight at least. Meaning that where you have the frown, that would become the new size of the razor. If you are loosing too much metal, it might not be worth it. Any pictures?

Almost any frown is fixable by careful honing, but the solution is to remove enough metal from the extremities of the blade to make the edge a straight line again. In other words, when you have a blade that is already pretty worn down AND it has a frown, then the amount of metal you have to remove plus the wear already on the blade sometimes means that the job is not worth it.

Anyway, photos would help!

Anyway, photos would help!

- Thread starter

- #4

thanks for the replies, I will try to get a picture posted of it tonight.

A word of warning, and a tip...

The first few times I breadknifed a blade to get rid of a frown, I didn't remove enough metal! Now, PLEASE read my explanation carefully, for I am only speaking about a very small amount of metal when I say I didn't remove enough.

Initially, breadknifing made me nervous, so as soon as I thought the edge was flat, I started honing. Well, the whole blade honed nicely, but about 1/2 to 3/4 inch in the middle, in the center of where the frown was. In that location, it didn't get sharp at all!

In other words, even though I had removed enough metal to look straight, it wasn't enough metal! And, there was still the slightest frown.

Another time or two, I had a similar problem. But, instead of about 1/2 to 3/4 inch not getting sharp at all, it just got raspy. That little section developed burr edges very easily. Skipping details, what was happening was that the blade, in the center of the frown had enough metal removed to touch the hone, but barely touch the hone. So, it got sharper, but was in essence being held above the hone, making only light contact, when the rest of the blade on both sides of the frown made contact.

Two similar problems, both caused by not removing enough metal.

When you remove a frown, periodically hold the blade edge up with a light in the background. Move the blade so the light glints off the edge. As you do, you will see the area that glints grow larger and larger, and the area of the frown shrink. Finally, the frown will disappear and a glint will extend all along the blade. The area covered by the frown should glint also.

There isn't much metal removal difference between not enough, and just right. I'm only talking a small, small amount. But, it is enough to make the difference between success and failure.

The first few times I breadknifed a blade to get rid of a frown, I didn't remove enough metal! Now, PLEASE read my explanation carefully, for I am only speaking about a very small amount of metal when I say I didn't remove enough.

Initially, breadknifing made me nervous, so as soon as I thought the edge was flat, I started honing. Well, the whole blade honed nicely, but about 1/2 to 3/4 inch in the middle, in the center of where the frown was. In that location, it didn't get sharp at all!

In other words, even though I had removed enough metal to look straight, it wasn't enough metal! And, there was still the slightest frown.

Another time or two, I had a similar problem. But, instead of about 1/2 to 3/4 inch not getting sharp at all, it just got raspy. That little section developed burr edges very easily. Skipping details, what was happening was that the blade, in the center of the frown had enough metal removed to touch the hone, but barely touch the hone. So, it got sharper, but was in essence being held above the hone, making only light contact, when the rest of the blade on both sides of the frown made contact.

Two similar problems, both caused by not removing enough metal.

When you remove a frown, periodically hold the blade edge up with a light in the background. Move the blade so the light glints off the edge. As you do, you will see the area that glints grow larger and larger, and the area of the frown shrink. Finally, the frown will disappear and a glint will extend all along the blade. The area covered by the frown should glint also.

There isn't much metal removal difference between not enough, and just right. I'm only talking a small, small amount. But, it is enough to make the difference between success and failure.

A Honemeister will be able to get rid of a frown without too many problems. As JeffE said, it might not be worth it though depending on the condition and size of the blade. By either taping or lifting the spine when removing the excess steel of the frown, you can do it without adding to the obvious hone wear.

- Thread starter

- #7

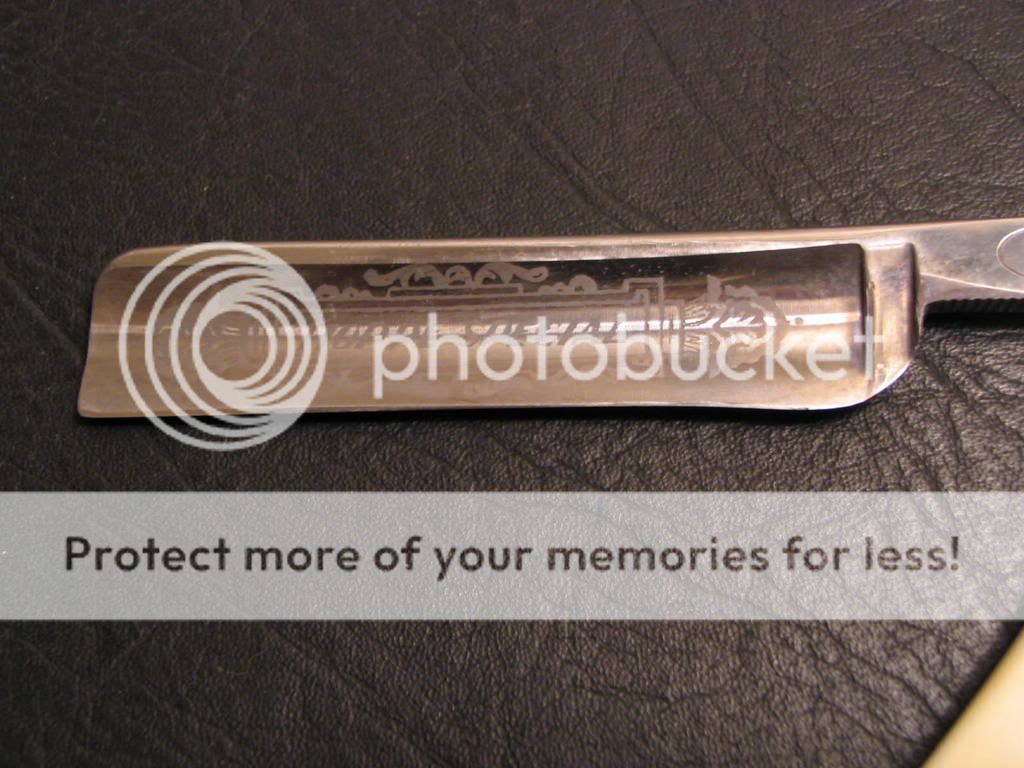

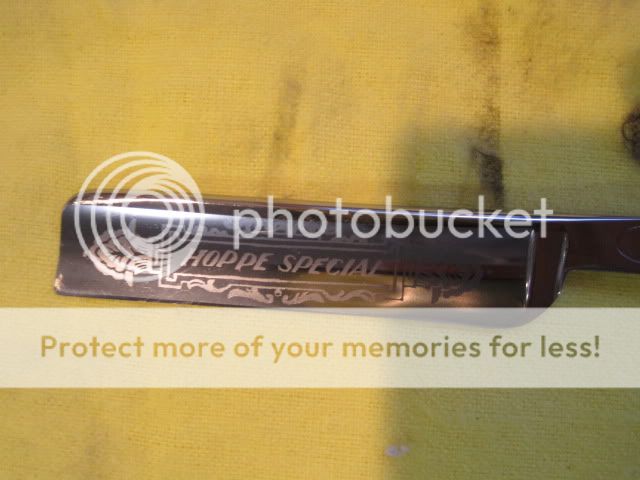

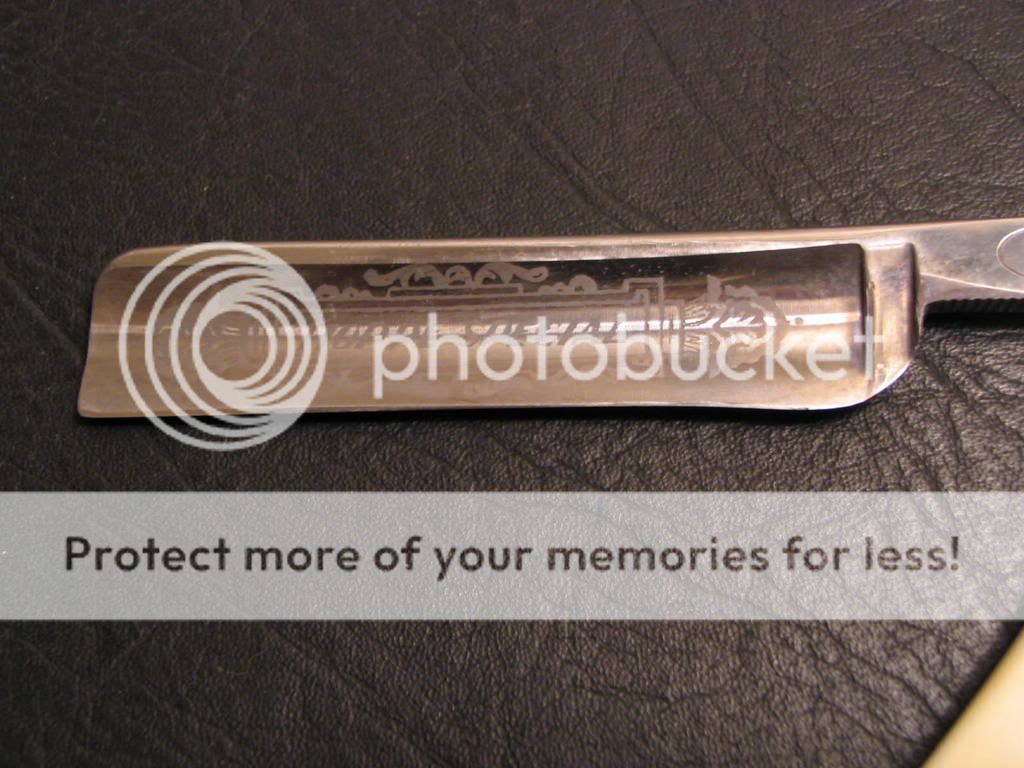

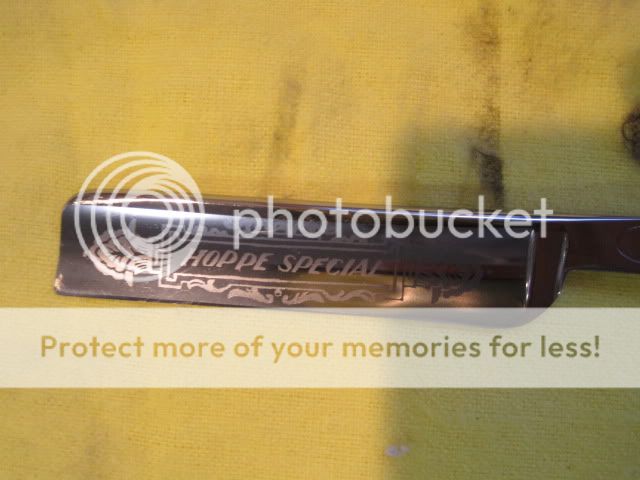

appreciate the continued replies... here are a few pictures of it.

i guess it doesn't look as bad as i thought, but advice on the best route would be appreciated.

i guess it doesn't look as bad as i thought, but advice on the best route would be appreciated.

That's well worth doing. It's a nice looking razor. Any honemeister should be able to sort that out for you.

That's no so bad. I would save it!

Looks like you're going to have to grind up close to or into that stabilizer. Also looks like a lot of hone wear which might be a continuing problem, especially at the tip.

- Thread starter

- #11

so is butterknifing on some sandpaper/flat surface the best way to start this out? i'm not overly concerned if this doesn't turn out perfect, this thing has been sitting in my 'to do' pile for about 5 years and it didn't cost much.

Slash McCoy

I freehand dog rockets

so is butterknifing on some sandpaper/flat surface the best way to start this out? i'm not overly concerned if this doesn't turn out perfect, this thing has been sitting in my 'to do' pile for about 5 years and it didn't cost much.

Or a very coarse el cheapo DMT. I get mine from Harbor Freight and they are very cheap. I have only messed with a couple of frownies but I think a coarse throwaway DMT is a good way to go.

With paper, you wouldn't want to use a true breadknifing technique, I don't think. You will just cut up the paper. What I would do with paper and a razor with less potential than yours is to hone on the paper at a really high angle but not the 90 degree angle of breadknifing. Works the same way. You are still only removing metal that MUST be removed ANYWAY. I have never actually done it that way which is why I wouldn't try it on a nice razor like yours. I would go get a cheap coarse stone and breadknife.

Checking your progress is easier if you stop and give the blade a few strokes on a finer stone, say 1K rather than the 300 or so I would use as a coarse stone. The finer stone will make nice shiny surfaces that you can see easily. Breadknifing is all about that reflecty surface. You should see reflected light from the flat all up and down the blade, though it is okay if that flat is only barely wide enough to see it in places. That tells you that you finally have a nice straight edge. Then back to the coarse stone to set a bevel, and this part is critical so work carefully. It is tempting, when you know you have a lot of steel to remove, to bear down a bit, but that's a bad thing. Concentrate on establishing a nice flat bevel. Light to moderate pressure. Let the stone do the work. When you want to check your progress, stop and hit the 1K or a finer stone for a few laps, so you can see the flat of the bevel more easily. When the flats extend all the way to the edge on both sides and all down the length of the blade, AND you can turn the blade edge-up and examine it the way you did while breadknifing and see NO reflection from the edge, you are only then ready to start progressing up through the normal stone progression. I think I have wasted more time trying to do the work on a 1K or 4K that I should have done on a coarser stone than I want to talk about. That extra 100 laps on the coarse rock when you think MAYBE it is time to move up, might save you 2000 laps on the finer stones. When you are bringing back a razor like yours, the coarse stones are your friends. Stones you would not use to sharpen your buck knife are gonna save you hours and hours, if you don't mess up. Messing up, of course, is greatly enhanced when doing it on a coarse stone. Been there, done that.

Similar threads

- Replies

- 14

- Views

- 980

- Replies

- 16

- Views

- 1K