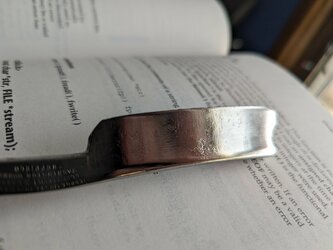

I had picked up a lot of razors mostly aiming at a W&B, but this guy was in there as well. Original condition is seen as it is the top razor in the first picture below. I decided with a little spare time before summer comes, I'd take a blade I'm not invested in and see what I could do. The after pictures follow. Excuse my fingerprints on the tang.

My question is - how far / how much material would you go down to get that perfect finish? The staining and some pitting go somewhat deep and it seemed like a fool's errand to sand it down that far. The finish is pretty good polished finish but the staining in certain light is still present and it isn't a fully "mirror" finish.

Thoughts? Obviously if the starting point was much cleaner and less staining/pitting the mirror is more achievable but trying to gauge how far one goes.

Thanks!

My question is - how far / how much material would you go down to get that perfect finish? The staining and some pitting go somewhat deep and it seemed like a fool's errand to sand it down that far. The finish is pretty good polished finish but the staining in certain light is still present and it isn't a fully "mirror" finish.

Thoughts? Obviously if the starting point was much cleaner and less staining/pitting the mirror is more achievable but trying to gauge how far one goes.

Thanks!