Here's one for those of you who know machine/metal work better than I do...

I am trying to revive my "Lock-A-FOCS" project. Basically this is a small modification to allow for a screw to be inserted up from the bottom of the handle to jam against the end of the threaded stud on the cap, once it's screwed into the handle. The intent is to allow for opening up the razor just a little in a safer and more secure way. We've lately seen @Clouds and @Tanuki displaying the fruits of their labours during the OCtober thread.

Last time I tried that with the FOCS the handle was too loose and things got a little frightening tout suite.

The FOCS seems like a good fit to the project, as the ferrule at the top of the handle is through-drilled and the handle is hollow. That ferrule is just a millimetre or so longer than 7/8" -- why they needed a ferrule that long I don't know; further I can't fathom why they didn't run their darn tap all the way through. But no matter. If I can source the tool I can do the work.

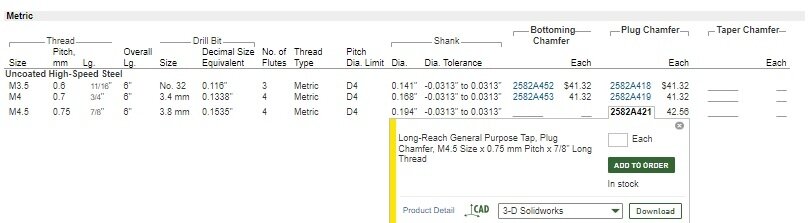

There's a lot about taps I never had to know. This allows me to be open-minded. The tap needs to be M4.5 x 0.75 thread pitch, and I'd want the "length of cut" to be at least an inch/2.5 cm to allow for getting good threads all the way down. I've got a standard length tap in that pitch and it "shoulders out" before it can cut all the way through.

The tap needs to be M4.5 x 0.75 thread pitch, and I'd want the "length of cut" to be at least an inch/2.5 cm to allow for getting good threads all the way down. I've got a standard length tap in that pitch and it "shoulders out" before it can cut all the way through.

I have figured out that a "deep hole" tap is likely not what I want, as they seem to be standard cutters on longer shafts.

So there it is. I would like a couple of things: what that specific style of tap is called, so I can sound knowledgeable ; and a source that is either in or ships to Canada. Thanks in advance for any insight or assistance!

; and a source that is either in or ships to Canada. Thanks in advance for any insight or assistance!

O.H.

I am trying to revive my "Lock-A-FOCS" project. Basically this is a small modification to allow for a screw to be inserted up from the bottom of the handle to jam against the end of the threaded stud on the cap, once it's screwed into the handle. The intent is to allow for opening up the razor just a little in a safer and more secure way. We've lately seen @Clouds and @Tanuki displaying the fruits of their labours during the OCtober thread.

Last time I tried that with the FOCS the handle was too loose and things got a little frightening tout suite.

The FOCS seems like a good fit to the project, as the ferrule at the top of the handle is through-drilled and the handle is hollow. That ferrule is just a millimetre or so longer than 7/8" -- why they needed a ferrule that long I don't know; further I can't fathom why they didn't run their darn tap all the way through. But no matter. If I can source the tool I can do the work.

There's a lot about taps I never had to know. This allows me to be open-minded.

The tap needs to be M4.5 x 0.75 thread pitch, and I'd want the "length of cut" to be at least an inch/2.5 cm to allow for getting good threads all the way down. I've got a standard length tap in that pitch and it "shoulders out" before it can cut all the way through.

The tap needs to be M4.5 x 0.75 thread pitch, and I'd want the "length of cut" to be at least an inch/2.5 cm to allow for getting good threads all the way down. I've got a standard length tap in that pitch and it "shoulders out" before it can cut all the way through.I have figured out that a "deep hole" tap is likely not what I want, as they seem to be standard cutters on longer shafts.

So there it is. I would like a couple of things: what that specific style of tap is called, so I can sound knowledgeable

O.H.